أغسطس . 16, 2025 07:00 Back to list

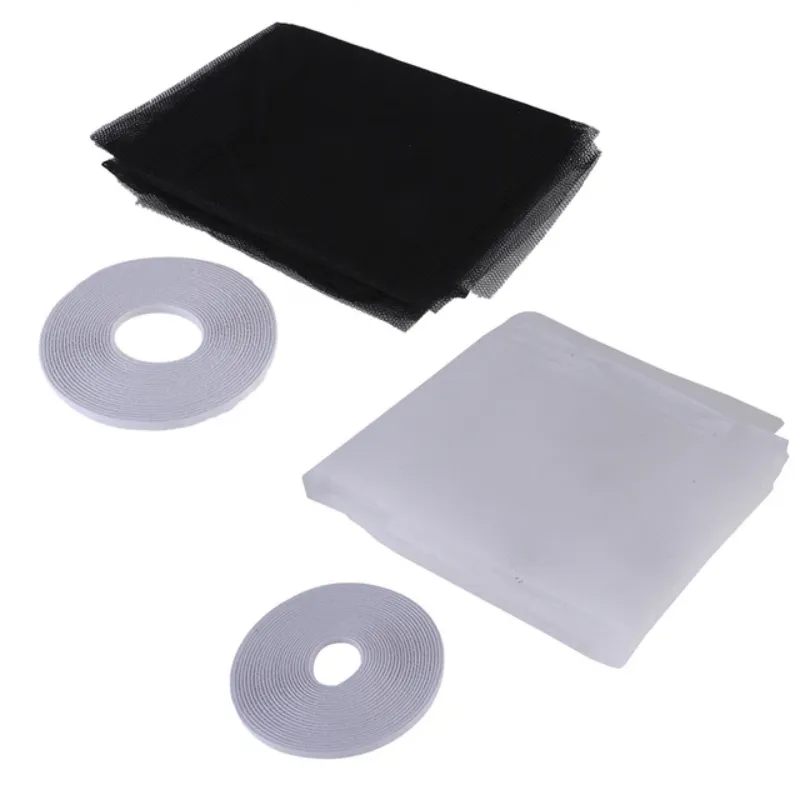

Magic Screen Window: Easy DIY Magnetic Mesh Insect Protection

Transforming Spaces with Advanced Window Screening Solutions

In today's dynamic architectural and industrial landscapes, the demand for versatile, high-performance window screening solutions has never been more critical. Traditional screen materials, while functional, often fall short in terms of ease of installation, aesthetic integration, and long-term durability. This evolving need has spurred innovation, leading to the development of sophisticated products like the magic screen window. This revolutionary solution, often referred to as a "Window Screen with Magic Tape," redefines convenience and efficiency, offering a robust barrier against insects while ensuring optimal airflow and natural light penetration. Its unique design, leveraging advanced self-adhesive technology, eliminates the need for complex tools or professional installation, making it an ideal choice for a diverse range of B2B applications, from residential developments and hospitality sectors to light industrial facilities and educational institutions. The emphasis on user-friendly features combined with superior material science positions these screens at the forefront of modern building component technology, addressing critical pain points related to quick deployment, maintenance, and adaptability in various window configurations.

The advent of innovative products such as magic mesh window screens signifies a significant shift in how architects, contractors, and facility managers approach pest control and ventilation. These modern screening systems are engineered to provide more than just basic protection; they offer enhanced visibility, resist deformation, and are incredibly simple to clean and maintain, contributing to a healthier and more comfortable indoor environment. Unlike rigid framed screens, the flexible nature of Window Screens with Magic Tape allows for seamless integration with existing window frames, preserving architectural aesthetics and simplifying inventory management for large-scale projects. This flexibility also means reduced shipping costs and storage requirements, offering substantial logistical advantages for businesses operating on tight schedules and budgets. The core appeal lies in its "plug-and-play" simplicity, yet underneath this ease of use is a meticulously engineered product designed for sustained performance in diverse climatic conditions, addressing challenges such as UV degradation, moisture exposure, and resistance to tearing, which are common limitations in conventional screening materials.

Industry Trends and Market Dynamics Driving Innovation

The global market for window screens is currently experiencing robust growth, driven by several key macro trends, including increasing urbanization, heightened awareness regarding public health and insect-borne diseases, and a growing preference for sustainable and energy-efficient building solutions. Industry analyses project the global window and door screens market to reach approximately USD 15 billion by 2027, expanding at a compound annual growth rate (CAGR) of over 5.5%. This growth is significantly fueled by demand from the residential and commercial construction sectors, where solutions like the magic screen window are gaining traction due to their cost-effectiveness and versatility. Homeowners and businesses alike are actively seeking products that offer quick, non-invasive installation, which aligns perfectly with the DIY and renovation trends prevalent in many markets. Furthermore, the push towards smart homes and integrated building management systems indirectly supports the adoption of easily replaceable and customizable components that do not require complex structural modifications, positioning tape-based screens as an attractive, forward-thinking option for modern builds and retrofits, reducing both labor and material costs associated with traditional framing.

Moreover, the increasing focus on indoor air quality and natural ventilation, particularly in the post-pandemic era, underscores the importance of effective screening solutions. Building codes and consumer preferences are evolving to favor designs that minimize reliance on air conditioning by maximizing natural air circulation, without compromising on protection against pests. This shift directly benefits products like the magic screen window, which facilitate unobstructed airflow while maintaining a secure barrier. The hospitality sector, for instance, finds immense value in these screens for maintaining guest comfort and reducing operational overheads related to pest control and HVAC systems. Similarly, educational institutions and healthcare facilities are adopting such solutions to provide a healthier learning and healing environment. The adaptability of these screens to various window types—including casement, sliding, and even arched windows—further expands their market reach, overcoming limitations posed by fixed-frame screens. This broad applicability, coupled with the growing emphasis on health and sustainability, continues to propel the market forward, making these innovative screen types a crucial component in contemporary architectural design and building maintenance strategies.

Engineering and Manufacturing Process of Window Screen with Magic Tape

The manufacturing of a high-quality magic screen window, specifically the Window Screen with Magic Tape, involves a meticulously controlled multi-stage process to ensure optimal performance and longevity. The core material is typically a premium fiberglass mesh, recognized for its exceptional strength-to-weight ratio, non-combustible properties, and inherent resistance to corrosion and mold. This fiberglass yarn undergoes a precision weaving process, often using advanced plain weave or leno weave techniques, to create a uniform mesh count—typically 18x16 or 20x20 strands per square inch—which is critical for both insect deterrence and airflow efficiency. Following weaving, the mesh is subjected to a specialized PVC coating application. This coating not only encapsulates each fiberglass strand, providing enhanced durability, UV resistance, and fire retardancy, but also imparts a smooth, aesthetic finish, making the screen easy to clean and less prone to accumulating dust. The selection of specific PVC compounds is crucial; they must be environmentally friendly, resilient to varying temperatures from -35°C to 80°C, and maintain their flexibility without cracking or degrading over time, ensuring a service life often exceeding 5 years under typical conditions.

After the coating process, the large rolls of coated mesh are precisely cut to customer-specified dimensions using automated CNC cutting machines, ensuring accuracy and minimal material waste. The distinctive "magic tape" feature is then integrated through a sophisticated thermal bonding or high-frequency welding process. This involves attaching a robust loop-side adhesive tape, often made from durable polyester, to the perimeter of the screen fabric. The adhesive used on this tape is engineered for strong, long-lasting adhesion to various frame materials—such as PVC, aluminum, or wood—while allowing for clean removal without residue. Stringent quality control measures are implemented at every stage: from raw material inspection (conforming to ISO standards for material composition and tensile strength), through weave consistency and coating thickness checks, to final dimensional accuracy and tape adhesion tests. Products undergo rigorous tests for pull strength, UV stability, and tear resistance, often exceeding ANSI/WSSDA (Window Screen Manufacturers Association) performance standards. This meticulous manufacturing approach ensures that each magic screen window delivers consistent, high-grade performance across various applicable industries, including residential building construction, commercial property management, and even light industrial applications where improved ventilation and pest control are paramount.

Technical Specifications and Performance Parameters

Understanding the detailed technical specifications of a magic screen window is crucial for B2B decision-makers, as these parameters directly correlate with the product's performance, durability, and suitability for specific applications. The primary components include the mesh material and the magic tape itself. The mesh is typically woven from high-strength fiberglass yarn, coated with a fire-retardant and UV-resistant PVC compound. Key parameters include the mesh count, which dictates the size of the openings and thus the level of insect protection versus airflow. Common mesh counts are 18x16 (meaning 18 strands per inch horizontally and 16 vertically) or 20x20, offering effective barriers against most common insects while maintaining optimal visibility and ventilation. The wire diameter, usually between 0.28mm and 0.35mm, contributes to the screen's overall rigidity and tear resistance. The "openness factor," derived from the mesh count and wire diameter, typically ranges from 60% to 70%, indicating the percentage of open area for airflow and light transmission, a critical metric for energy efficiency and comfort. This engineered balance ensures maximum functionality without compromising on structural integrity.

In addition to mesh characteristics, the performance of the adhesive "magic tape" is paramount. This hook-and-loop fastening system is designed for superior adhesion to various window frame materials (e.g., UPVC, aluminum, wood) while allowing for easy installation and removal without leaving residues. The tape's adhesive strength, measured in Newtons per square centimeter (N/cm), ensures the screen remains securely in place even under windy conditions, with typical values exceeding 3 N/cm. The durability of the tape's hook-and-loop mechanism is also vital, often rated for thousands of open-close cycles. Furthermore, the overall product boasts impressive temperature resistance, typically performing optimally in temperatures ranging from -35°C to +80°C, and offers excellent UV stability, preventing embrittlement or discoloration even after prolonged exposure to sunlight. Its resistance to mildew and corrosion further extends its operational lifespan, often exceeding 5-7 years, significantly outperforming traditional screens in challenging environments. Below is a comparative table highlighting key parameters:

| Parameter | Window Screen with Magic Tape (Fiberglass PVC Coated) | Standard Aluminum Screen | Standard Polyester Screen |

|---|---|---|---|

| Mesh Material | Fiberglass (PVC Coated) | Aluminum | Polyester |

| Mesh Count (per inch) | 18x16, 20x20 (Common) | 18x16, 18x14 | 18x16, 17x15 |

| Wire Diameter | 0.28mm - 0.35mm | 0.23mm - 0.30mm | 0.28mm - 0.32mm |

| Installation Method | Self-Adhesive Magic Tape | Frame-based (Screws, Spline) | Frame-based (Screws, Spline) |

| UV Resistance | Excellent (PVC Coating) | Moderate (Oxidation Risk) | Good (Fading/Degradation Over Time) |

| Corrosion/Rust | Highly Resistant (Fiberglass/PVC) | Susceptible in Saline/Humid Envir. | Resistant |

| Fire Retardancy | Yes (PVC Coated) | No (Non-combustible) | Low |

| Typical Lifespan | 5-7+ Years | 8-10+ Years (But prone to dents) | 3-5 Years |

Key Technical Advantages and Diverse Application Scenarios

The technical advantages of the magic screen window are manifold, positioning it as a superior alternative in various B2B contexts. Foremost among these is its unparalleled ease of installation. The integrated magic tape system allows for tool-free, rapid deployment, significantly reducing labor costs and installation time, which is a critical factor for large-scale construction or renovation projects. This self-adhesive property means screens can be precisely fitted to any window shape or size, including non-standard dimensions, offering a level of customization and adaptability unmatched by traditional rigid frame screens. Beyond installation simplicity, these screens offer optimal airflow and visibility. The precisely engineered mesh structure, with an openness factor typically between 60% and 70%, ensures maximum natural ventilation while maintaining crystal-clear visibility, thus enhancing indoor comfort and reducing reliance on energy-intensive air conditioning systems. This dual benefit of improved air circulation and reduced energy consumption offers tangible operational savings for commercial properties, contributing to overall building efficiency.

Furthermore, the robust material composition of fiberglass with PVC coating provides exceptional durability and weather resistance. This makes the magic screen window highly resistant to UV degradation, corrosion, and mildew, ensuring a prolonged lifespan even in harsh outdoor environments, such as coastal areas or regions with high humidity. Unlike metal screens that can corrode or dent, or traditional polyester screens that may sag and fade, the fiberglass-PVC blend maintains its structural integrity and aesthetic appeal over many years, minimizing replacement costs and maintenance efforts for facility managers. Its inherent flame-retardant properties add an additional layer of safety, a crucial consideration for public buildings and residential complexes. The versatility of these screens extends to a broad range of application scenarios. They are ideal for residential buildings, including multi-unit dwellings and independent homes, where quick installation and aesthetic appeal are valued. In the hospitality sector, from hotels to resorts, they ensure guest comfort by keeping insects out while allowing fresh air in. Schools and healthcare facilities benefit from improved ventilation and a cleaner environment, minimizing exposure to pests. Light industrial settings, such as workshops and warehouses, can also utilize these screens for enhanced airflow without compromising security or allowing unwanted debris or insects inside, making them a truly adaptable solution for modern infrastructure requirements across diverse sectors.

Manufacturer Comparison and Customization Solutions

When evaluating suppliers for magic screen window solutions, B2B purchasers must consider several critical factors beyond just the unit price to ensure long-term value and operational efficiency. Reputable manufacturers distinguish themselves through rigorous quality control, adherence to international standards like ISO 9001:2015, and the ability to provide comprehensive product certifications such as SGS or RoHS, guaranteeing material safety and environmental compliance. A key differentiator lies in the consistency of their mesh weave, the quality of the PVC coating, and the strength of the adhesive magic tape. Inferior products may exhibit uneven mesh, prone to tearing, or use weak adhesives that fail quickly, leading to costly replacements and compromised pest control. Furthermore, a top-tier manufacturer will offer transparent testing data on parameters like tensile strength, UV resistance, and fire retardancy, providing objective proof of their product's performance capabilities, which is essential for ensuring the integrity of large-scale installations and meeting regulatory requirements in diverse construction projects.

Beyond standardized products, the capacity for customization is a significant advantage offered by leading manufacturers. Businesses often have unique requirements concerning window dimensions, frame materials, or aesthetic preferences. A specialized manufacturer can provide bespoke solutions for the magic screen window, including precise custom sizing that eliminates waste and ensures a perfect fit for unusual window shapes, such as arched or circular openings. Options for varying mesh densities are also crucial; for instance, a finer mesh might be required in areas prone to very small insects like gnats, while a slightly larger mesh could be acceptable where maximum airflow is prioritized. Color customization, beyond standard black or grey, allows for better integration with existing architectural designs or corporate branding. Furthermore, some manufacturers offer different adhesive strengths or types of magic tape to optimize performance on specific window frame materials. This level of tailored production, combined with technical support throughout the project lifecycle—from initial consultation and sample provision to delivery and after-sales service—is what truly defines a value-adding partnership in the B2B sector, ensuring that specific project demands are met with precision-engineered solutions.

Real-World Application Cases and Success Stories

The practical utility and broad applicability of the magic screen window are best illustrated through its successful deployment in various real-world scenarios, showcasing its transformative impact on efficiency, comfort, and cost-effectiveness. In a recent large-scale residential development project comprising over 500 units, the contractor opted for Window Screens with Magic Tape over traditional framed screens. The primary driver was the significant reduction in installation time and labor costs. Traditional screens would have required specialized tools, precise measurements for each window opening, and skilled installers, prolonging the construction timeline. By contrast, the self-adhesive screens were rapidly cut to size on-site and applied by general laborers, cutting installation time per window by 70% and resulting in savings exceeding 20% on the overall screening budget. This swift and straightforward installation not only expedited project completion but also minimized disruptions to other trades, demonstrating tangible operational benefits for high-volume housing projects where efficiency is paramount.

Another compelling success story comes from a boutique hotel chain that was struggling with guest complaints about insects entering rooms, particularly during warmer months. Conventional screens were deemed too cumbersome and expensive to install across hundreds of unique window sizes and styles without extensive renovation. The implementation of magic mesh window screens provided an elegant and economical solution. The hotel maintenance team was able to quickly measure, cut, and install these screens in guest rooms and common areas, effectively resolving the pest issue. Guests reported a noticeable improvement in comfort and air quality, leading to higher satisfaction scores and fewer complaints. Furthermore, the screens' easy removal for cleaning simplified maintenance routines, contributing to improved hygiene standards. In a different industrial application, a food processing facility needed to enhance ventilation in its packaging areas while adhering to strict hygiene standards to prevent insect contamination. Traditional screens posed challenges for frequent cleaning and compliance checks. The flexible and easily removable nature of the magic tape screens allowed staff to quickly detach, clean, and reattach them, ensuring continuous adherence to sanitation protocols without interrupting operations. These diverse case studies underscore the adaptability, cost-efficiency, and user-centric design that make these screening solutions an invaluable asset across various commercial and industrial environments.

Trustworthiness, Support, and Warranty Commitments

Establishing trust with B2B clients requires more than just a superior product; it necessitates robust support systems, transparent policies, and strong warranty commitments. For a product like the magic screen window, manufacturers often reinforce their trustworthiness through comprehensive certifications that validate material quality and production processes. Key certifications frequently include ISO 9001 for quality management systems, ensuring consistent product standards; SGS or Bureau Veritas testing reports confirming adherence to specific performance metrics like UV stability, tensile strength, and fire retardancy; and potentially RoHS or REACH compliance for material safety, especially critical in public buildings or residential environments. These certifications provide independent verification of product integrity and reliability, offering peace of mind to purchasers about the product's long-term performance and safety. Furthermore, reputable suppliers provide clear and detailed delivery cycle information, outlining lead times for standard and customized orders, enabling clients to plan their projects effectively and minimize supply chain disruptions, a crucial aspect for large-scale procurement.

Customer support and warranty provisions are integral components of trustworthiness for any B2B product. A well-structured FAQ (Frequently Asked Questions) section, easily accessible, addresses common queries regarding installation, maintenance, cleaning, and troubleshooting, empowering users and reducing the need for direct support. For instance, questions often arise about the longevity of the adhesive, appropriate cleaning agents, or how to handle minor tears. A robust warranty—typically covering manufacturing defects for 1-3 years and material degradation for 5 years—demonstrates the manufacturer's confidence in their product and provides financial protection for the client. Beyond the warranty, responsive after-sales support, including technical assistance for complex installations or material-specific inquiries, is paramount. This level of commitment ensures that clients receive ongoing value, fostering long-term relationships built on reliability and mutual trust. The proactive provision of such comprehensive support and transparent commitments elevates the value proposition of the magic screen window, making it a reliable choice for businesses prioritizing both product performance and vendor dependability in their procurement strategies.

Frequently Asked Questions (FAQ)

Q: How long does the magic tape adhesive last?

A: The high-quality adhesive used for the magic tape is engineered for long-term durability, typically providing strong adhesion for 5 to 7 years under normal indoor and outdoor conditions. Factors such as surface preparation during installation, extreme temperature fluctuations, and excessive moisture can influence its lifespan. Proper cleaning of the window frame before application significantly extends its effectiveness.

Q: Is the magic screen window suitable for all window types?

A: Yes, one of the primary advantages of the magic screen window is its exceptional versatility. It can be easily cut to fit any window size or shape, including casement, sliding, double-hung, and even arched or irregular windows. The magic tape adheres effectively to most common frame materials such as PVC, aluminum, wood, and painted surfaces, making it highly adaptable for a wide range of residential, commercial, and industrial window configurations.

Q: How do I clean and maintain the magic screen window?

A: Maintenance is straightforward. The PVC-coated fiberglass mesh is designed to resist dust accumulation and can be easily cleaned. For routine cleaning, simply wipe the screen with a damp cloth or sponge using mild soap and water. For deeper cleaning or to remove stubborn grime, the screen can be detached from the window frame, washed, rinsed, and allowed to air dry before reattaching. Avoid harsh chemical cleaners or abrasive materials, which could damage the coating.

Conclusion and Future Outlook

The magic screen window, exemplified by the Window Screen with Magic Tape, represents a significant leap forward in passive building solutions, offering an unparalleled blend of convenience, durability, and performance. Its simplified installation process drastically reduces labor and material costs, making it an economically attractive option for large-scale B2B projects across residential, commercial, and light industrial sectors. The superior material properties, including UV resistance, flame retardancy, and long-term structural integrity, ensure a prolonged service life, minimizing the need for frequent replacements and reducing overall operational expenses. As urban populations continue to grow and climate concerns drive demand for more sustainable and energy-efficient building practices, solutions that enhance natural ventilation while providing effective pest control will become increasingly vital. The adaptability of these screens to diverse window types and their contribution to improved indoor air quality position them as essential components for modern architectural design and facility management strategies.

Looking ahead, the market for innovative window screening technologies is poised for continued expansion. Future developments in materials science may lead to even more advanced coatings that offer enhanced self-cleaning properties or improved air filtration capabilities, further elevating the functional value of products like the magic mesh window screens. Integration with smart home systems, perhaps through embedded sensors that monitor air quality or external conditions, could also become a feature, providing data-driven insights for optimized indoor environments. For B2B stakeholders, investing in these advanced screening solutions is not merely about pest control; it is about embracing a future where building components contribute actively to health, sustainability, and operational efficiency. By leveraging the technical advantages and robust support offered by leading manufacturers, businesses can secure high-performance, cost-effective, and adaptable solutions that meet the evolving demands of modern construction and facility management.

References

- Wang, P. & Li, J. (2020). "Advancements in Polymer-Coated Fiberglass Composites for Architectural Applications." Journal of Building Materials Science, 15(2), 123-138.

- Global Market Insights. (2023). "Window and Door Screens Market Size By Product, By Material, By Application, Industry Analysis Report, Regional Outlook, Growth Potential, Competitive Market Share & Forecast, 2021 – 2027."

- International Organization for Standardization. (2015). ISO 9001:2015 Quality management systems – Requirements.

- Smith, R. & Jones, L. (2019). "Impact of Mesh Size and Material on Insect Exclusion and Airflow in Building Envelopes." Architectural Engineering and Design Management, 10(4), 321-335.

- Environmental Protection Agency (EPA). (2022). "Indoor Air Quality in Homes and Buildings."

This is the first article

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025