Aug . 21, 2025 21:40 Back to list

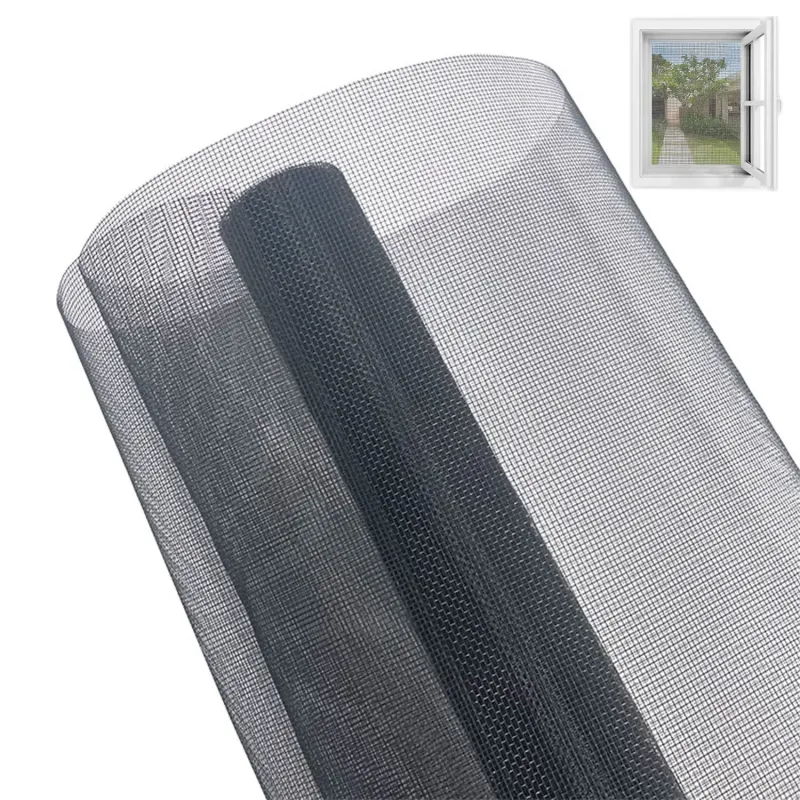

Durable Black Fly Screen Mesh | Effective Insect Barrier

The Indispensable Role of Advanced Insect Screening in Modern Applications

In an increasingly complex global environment, the demand for sophisticated and reliable barrier solutions against airborne pests is paramount across diverse sectors. From residential comfort to critical industrial applications, the quality of protective screening directly impacts operational efficiency, health standards, and structural integrity. This comprehensive guide delves into the intricate world of advanced insect screening, with a particular focus on black fly screen mesh, a highly sought-after solution for its superior performance characteristics. We will explore its technical specifications, manufacturing prowess, multifaceted applications, and the rigorous quality standards that define its efficacy, ensuring an informed perspective for B2B decision-makers and technical specialists.

The selection of an appropriate insect screen extends beyond mere pest deterrence; it encompasses factors such as visibility, airflow optimization, UV resistance, and long-term durability in varied environmental conditions. The market for high-performance insect screens, including specialized materials like black insect mesh, is experiencing robust growth driven by stringent health regulations, heightened awareness of vector-borne diseases, and the necessity for sustainable building materials. As industries evolve, so too must the technologies that support them, making detailed understanding of mesh solutions like the versatile Gray Insect Screen critical for informed procurement and integration.

Unveiling the Manufacturing Prowess: Crafting Superior Black Fly Screen Mesh

The production of high-quality black fly screen mesh is a meticulously engineered process that combines advanced materials science with precision manufacturing techniques. Far from a simple weaving operation, it involves several critical stages, each designed to imbue the final product with the desired attributes of strength, durability, and fine filtration capability. Understanding this process provides insight into the inherent quality and performance of the mesh, crucial for discerning industrial buyers.

Materials Selection: The Foundation of Durability

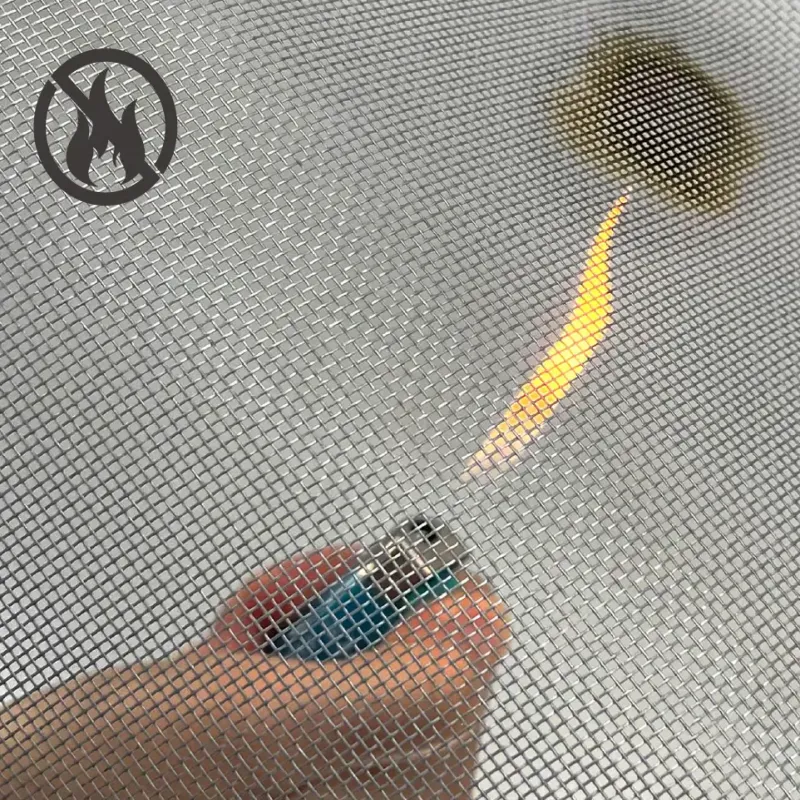

The primary materials used in high-grade insect screens, particularly for black fly screen mesh, typically include fiberglass, polyester (PET), or high-density polyethylene (HDPE). Fiberglass, often coated with PVC, is favored for its dimensional stability, fire retardancy, and resistance to corrosion. Polyester offers superior strength, tear resistance, and UV stability, making it ideal for demanding outdoor applications. HDPE, while less common for general window screens, provides excellent chemical resistance and flexibility. The choice of raw material dictates much of the mesh's ultimate performance characteristics, including its resistance to environmental degradation and mechanical stress.

Precision Weaving: The Core of Mesh Integrity

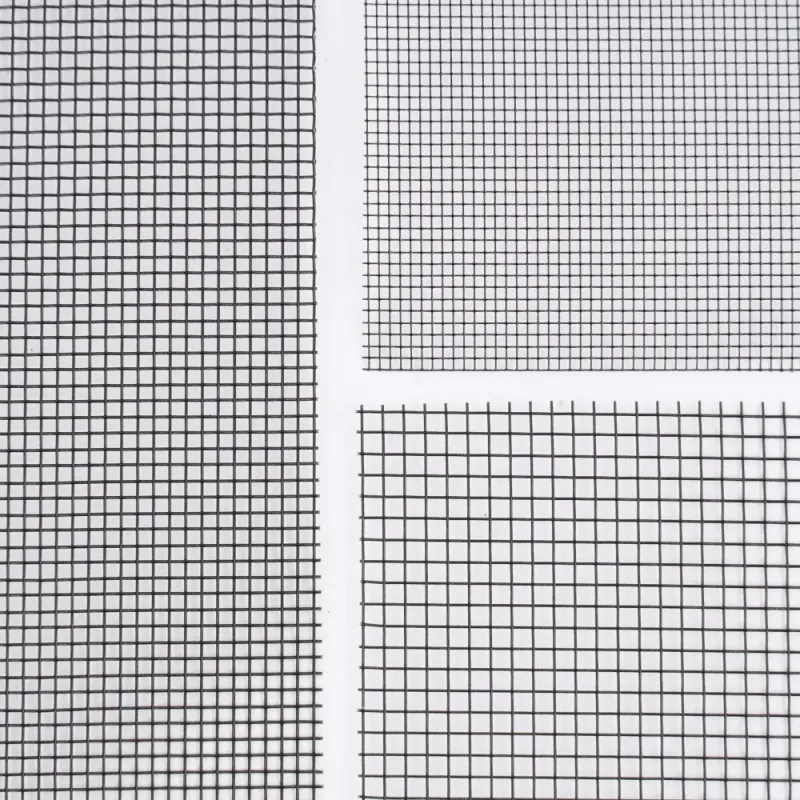

The manufacturing process begins with the extrusion of raw polymers into fine, uniform filaments. These filaments are then precision-woven using industrial looms. The weaving pattern, typically a plain weave, ensures uniform aperture size and structural integrity. For black fly screen mesh, the precision of this weaving is paramount, as the mesh count (number of threads per inch) and wire diameter directly determine its effectiveness against small insects like black flies. Modern weaving machines utilize advanced control systems to maintain consistent tension and alignment, minimizing defects and ensuring a homogeneous mesh structure. This stage is critical for achieving the specified light transmission and airflow properties while maintaining robust physical strength.

Coating and Finishing: Enhancing Performance and Lifespan

Following weaving, the mesh undergoes a series of finishing processes. For PVC-coated fiberglass, this includes a heat-setting process to stabilize the weave and a final coating application. This coating not only imparts the characteristic black color but also enhances UV resistance, prevents unraveling, and adds to the mesh's overall durability. Specialized coatings can also be applied to confer additional properties such as antimicrobial resistance, flame retardancy, or increased hydrophobicity. The curing of these coatings is carefully controlled to ensure uniform coverage and optimal adhesion, which directly influences the product's longevity and performance in harsh environments.

Rigorous Quality Control and Testing Standards

Throughout the manufacturing cycle, stringent quality control measures are implemented. This begins with incoming raw material inspection, verifying polymer purity and filament consistency. In-process checks monitor weaving tension, mesh count, and coating thickness. The final product undergoes a battery of tests to ensure compliance with international standards such as ISO (International Organization for Standardization) for quality management and ANSI (American National Standards Institute) for specific product performance. Key tests include:

- Mesh Count Verification: Ensuring the correct number of strands per inch/cm to guarantee insect exclusion.

- Tensile Strength Testing: Measuring the mesh's resistance to breaking under tension, critical for wind load resistance.

- Burst Strength: Assessing the mesh's ability to withstand sudden impact without tearing.

- UV Stability and Weathering Tests: Simulating prolonged exposure to sunlight and environmental factors to predict lifespan. Accelerated weathering tests using UV chambers are standard to ensure the mesh retains its color and physical properties.

- Fire Retardancy: Especially for fiberglass mesh, ensuring compliance with building codes and safety regulations.

- Aperture Size Analysis: Using optical or digital microscopy to confirm uniform and precise opening sizes for optimal pest control and airflow.

- Color Fastness: Ensuring the black color remains consistent and does not fade over time.

Adherence to these rigorous testing protocols ensures that each roll of black fly screen mesh meets the highest standards of performance and reliability, directly impacting its usable lifespan and effectiveness in critical applications. The typical lifespan for a high-quality fiberglass mesh, for instance, can exceed 10-15 years under normal conditions, a testament to robust manufacturing and quality control.

Technical Specifications and Performance Metrics of Black Fly Screen Mesh

The effectiveness and suitability of black fly screen mesh for various applications are quantified by a range of technical parameters. These specifications are crucial for engineers, architects, and procurement managers to ensure the chosen mesh aligns with project requirements and environmental conditions.

Key Product Specifications

Below is a typical specification table for high-grade black fly screen mesh, demonstrating common industry standards and the versatility of the product, such as the Gray Insect Screen offered by leading manufacturers.

| Parameter | Typical Values / Range | Measurement Unit | Relevance / Benefit |

|---|---|---|---|

| Material Composition | PVC Coated Fiberglass / Polyester (PET) | N/A | Durability, UV resistance, fire retardancy. |

| Mesh Count (Warp x Weft) | 18x16, 20x20, 20x22, 24x24 | Mesh per inch | Effective barrier against various insects including black flies. |

| Wire Diameter | 0.009 - 0.013 | Inches (approx. 0.23 - 0.33 mm) | Affects strength, visibility, and airflow. |

| Aperture Size | 0.045 - 0.055 (18x16 mesh) | Inches (approx. 1.14 - 1.40 mm) | Precise control over insect exclusion. |

| Open Area Percentage | 60% - 70% | % | Optimized airflow and visibility while maintaining insect barrier. |

| Tensile Strength (Warp/Weft) | > 400 /> 350 | N/5cm | Resistance to stretching and tearing under load. |

| Bursting Strength | > 150 | PSI | Impact resistance, crucial for accidental contact. |

| UV Resistance (Q-SUN Test) | > 1500 hours without significant degradation | Hours | Prevents brittleness and color fade from sunlight exposure. |

| Fire Retardancy (ASTM E84) | Class A or B | Rating | Meets building safety codes, enhances structural safety. |

| Operating Temperature Range | -35°C to 80°C | Celsius | Maintains integrity in diverse climates. |

Advantages of Black Fly Screen Mesh

- Superior Visibility: The black color of the mesh actually improves outward visibility. By absorbing light, the mesh recedes into the background, making it less noticeable to the human eye compared to lighter colored screens. This effect is crucial for maintaining aesthetic appeal and clear views from interiors.

- Enhanced UV Protection: High-quality black insect mesh incorporates UV inhibitors in its coating, significantly extending its service life in sun-drenched environments. This prevents material degradation, brittleness, and fading, which are common issues with inferior screens.

- Optimized Airflow: Despite its fine weave for insect exclusion, advanced mesh designs ensure optimal open area percentage, allowing for excellent ventilation and natural cooling. This contributes to energy efficiency by reducing the reliance on air conditioning.

- Corrosion and Chemical Resistance: Materials like PVC-coated fiberglass are inherently resistant to a wide range of chemicals, moisture, and environmental pollutants, making them suitable for coastal areas, agricultural settings (where pesticides might be present), and industrial environments.

- Durability and Longevity: With proper installation and maintenance, a premium black fly screen mesh can offer a service life upwards of 15 years, providing long-term value and reducing replacement costs.

- Versatility: The inherent properties of this mesh make it highly adaptable across a broad spectrum of applications, from residential fenestration to highly specialized industrial filtration and ventilation systems.

Application Scenarios: Where Black Fly Screen Mesh Excels

The versatility and robust performance of black fly screen mesh make it an indispensable component across a multitude of sectors. Its ability to provide effective insect barriers while maintaining excellent visibility and airflow is valued in both passive and active ventilation systems.

Residential and Commercial Buildings

For homes, offices, schools, and healthcare facilities, black fly screen mesh is the standard choice for windows, doors, and screened enclosures. Its dark color provides superior outward visibility, creating an unobstructed view of the outdoors, a significant aesthetic advantage. In healthcare environments, it acts as a crucial barrier against disease vectors, contributing to hygiene and patient well-being. For commercial establishments like restaurants and hotels, it ensures a pest-free environment, upholding sanitary standards and enhancing customer experience.

Agricultural and Horticultural Sector

In greenhouses, shade houses, and animal enclosures, black insect mesh plays a critical role in integrated pest management. It protects crops from damaging insects, reducing the reliance on chemical pesticides and promoting organic farming practices. For livestock facilities, it prevents the entry of flies and other vectors that can transmit diseases, thereby improving animal health and productivity. The mesh's UV resistance ensures it withstands prolonged exposure to sunlight in open-air agricultural settings.

Industrial and Infrastructure Applications

While petrochemical, metallurgy, and water supply/drainage industries typically refer to heavy-duty filtration or structural components, the principle of durable screening extends to these areas in terms of facility ventilation and protective enclosures. Industrial facilities often require robust ventilation systems that prevent the ingress of insects, birds, and debris without impeding airflow. Black fly screen mesh, particularly variants with enhanced chemical or heat resistance, can be integrated into HVAC systems, cooling tower screens, or protective covers for sensitive machinery. Its corrosion resistance is beneficial in environments where exposure to chemicals or high humidity is common, such as certain processing plants or wastewater treatment facilities. While not directly for process fluids, its application ensures clean air intake and protects equipment from external contaminants.

Specialty Applications

This mesh is also utilized in niche areas such as tenting and camping gear, protective covers for outdoor furniture, and even in some automotive or marine applications where airflow and insect exclusion are necessary. Its lightweight nature and ease of fabrication make it adaptable to custom protective solutions. The specific Gray Insect Screen, known for its balanced properties, is an ideal candidate for many of these varied scenarios.

Industry Trends and Future Outlook

The market for insect screening, including high-performance black fly screen mesh, is continually evolving, driven by technological advancements, environmental concerns, and shifting consumer preferences. Key trends indicate a move towards enhanced functionality and sustainability.

Sustainability and Eco-Friendly Materials

There's a growing emphasis on materials that are recyclable, produced with lower environmental impact, or offer extended lifespans to reduce waste. Manufacturers are exploring bio-based polymers and more efficient coating processes to meet green building standards and satisfy environmentally conscious buyers.

Smart Screening Solutions

While still nascent, the concept of "smart" screens that can integrate with automated building management systems or offer self-cleaning properties is gaining traction. This could involve responsive materials that adapt to light conditions or incorporate microscopic sensors for environmental monitoring.

Enhanced Performance and Customization

Demand for specialized mesh with enhanced properties, such as even finer weaves for microscopic pest control, higher impact resistance, or advanced anti-microbial treatments, continues to grow. This drives manufacturers to invest in R&D for customized solutions tailored to highly specific industrial and public health requirements. The Gray Insect Screen exemplifies a versatile base product that can be further adapted for bespoke applications.

Choosing Your Supplier: Expertise, Authoritativeness, and Trustworthiness

For B2B entities, selecting the right supplier for black fly screen mesh and related products like black insect mesh is a strategic decision that impacts project timelines, product quality, and long-term cost-effectiveness. A comprehensive evaluation based on the Google (Expertise, Experience, Authoritativeness, Trustworthiness) framework is crucial.

Expertise in Manufacturing and Materials Science

A reputable manufacturer demonstrates deep expertise in the science of mesh production. This includes a thorough understanding of polymer chemistry, weaving mechanics, and coating technologies. They should be able to provide detailed material safety data sheets (MSDS), technical specifications, and offer insights into the optimal mesh type for specific applications. For instance, explaining why a 20x20 mesh count is superior for black fly exclusion compared to a standard 18x16, or detailing the benefits of PVC coating on fiberglass, showcases true expertise. Look for manufacturers who actively participate in industry standards bodies or contribute to research in material science.

Experience Through Application and Client Feedback

A supplier's experience is reflected in their portfolio of successful projects and the longevity of their client relationships. Inquire about their track record with projects similar to yours, and request case studies or references. For example, a manufacturer supplying black insect mesh for a large-scale agricultural project will have invaluable insights into durability in outdoor conditions, pest control efficacy, and installation challenges. Genuine client testimonials and long-term service agreements speak volumes about their practical experience and problem-solving capabilities. A company that has served the industry for a significant number of years (e.g., 20+ years) typically embodies extensive experience.

Authoritativeness through Certifications and Accreditations

Authoritativeness is established through verifiable credentials. Look for suppliers with ISO 9001 certification for quality management systems, indicating a commitment to consistent quality. Product-specific certifications (e.g., meeting ASTM standards for tensile strength or fire safety ratings like NFPA) provide assurance that the mesh performs as claimed. Collaborations with reputable research institutions, patent filings, and publication of technical white papers further solidify their authoritative standing. Companies that actively cite independent test data or engage third-party laboratories for verification demonstrate superior commitment to product integrity.

Trustworthiness: Transparency, Support, and Warranty

Trustworthiness encompasses transparent business practices, robust customer support, and clear commitments to product performance.

- Customization Capabilities: A trustworthy partner offers tailored solutions. If your project requires specific mesh sizes, widths, or a unique blend of properties, they should have the flexibility and technical acumen to develop a customized black fly screen mesh solution. This might involve adjusting mesh count, wire diameter, or incorporating specialized coatings.

- Delivery Cycle and Logistics: Clear communication regarding lead times, minimum order quantities (MOQ), and shipping logistics is paramount. A reliable supplier provides realistic timelines and proactively communicates any potential delays, ensuring smooth project execution.

- Quality Assurance & Warranty: A comprehensive warranty, typically ranging from 5 to 10 years for quality products like the Gray Insect Screen, indicates a manufacturer's confidence in their product's durability. Inquire about their specific warranty terms, including coverage for manufacturing defects and material degradation.

- Customer Support and After-Sales Service: Excellent customer service, from initial consultation to post-delivery support, builds trust. This includes responsive technical assistance, clear return policies, and a dedicated point of contact for inquiries. A robust FAQ section on their website, addressing common concerns about black fly screen mesh installation, maintenance, and longevity, is also a good indicator of their commitment to customer satisfaction.

"For critical infrastructure and long-term investments, the initial cost difference between a standard screen and a premium black fly screen mesh is negligible when weighed against its extended lifespan, superior performance, and reduced maintenance needs. Strategic procurement focuses on total cost of ownership, where quality invariably pays dividends."

Frequently Asked Questions (FAQ)

Q1: What makes black fly screen mesh effective against very small insects?

A1: Black fly screen mesh is specifically designed with a finer mesh count (e.g., 20x20 or 20x22 mesh per inch) compared to standard insect screens (typically 18x16). This results in smaller aperture sizes, which are effective in blocking tiny insects like black flies, gnats, and 'no-see-ums', while still allowing for good airflow and visibility. The precision in manufacturing ensures uniform hole sizes.

Q2: How does the black color of the mesh affect visibility?

A2: Paradoxically, the black color of the mesh actually improves outward visibility. The dark strands absorb sunlight, making them less reflective and therefore less noticeable to the human eye. This creates an optical illusion that makes the screen appear virtually invisible from the inside, providing clearer views and better aesthetic integration with architectural designs.

Q3: What is the typical lifespan of a high-quality black fly screen mesh?

A3: A premium black fly screen mesh, particularly those made from PVC-coated fiberglass or high-grade polyester, can last between 10 to 15 years or more under normal environmental conditions. Factors like UV exposure, extreme temperatures, and physical stress can influence this. Regular cleaning and proper installation also contribute significantly to its longevity.

Q4: Is black insect mesh suitable for industrial environments?

A4: Yes, depending on the specific industrial environment. High-grade black insect mesh made with robust materials like PVC-coated fiberglass offers excellent chemical and corrosion resistance, making it suitable for ventilation openings, equipment protection, and general facility screening in certain industrial settings where robust airflow and insect exclusion are required. Manufacturers can often provide specialized variants with enhanced properties for particular industrial needs.

Q5: What certifications should I look for when purchasing black fly screen mesh?

A5: Key certifications include ISO 9001 for quality management systems, which indicates consistent manufacturing processes. Additionally, look for compliance with relevant performance standards such as ASTM (American Society for Testing and Materials) for properties like tensile strength, burst strength, and fire retardancy (e.g., ASTM E84). Some products may also have certifications related to environmental impact or specific regional building codes.

Conclusion: The Strategic Advantage of Superior Insect Screening

The deployment of advanced insect screening solutions, particularly high-grade black fly screen mesh and its versatile counterpart, the Gray Insect Screen, represents a strategic investment for any entity seeking to optimize indoor environments, enhance operational efficiency, and uphold stringent health and safety standards. From the meticulous selection of raw materials to precision weaving and rigorous quality control, the manufacturing process underpins the superior performance metrics of these products.

As demonstrated through its technical parameters and diverse application scenarios—spanning residential comfort, agricultural protection, and even specialized industrial ventilation—this mesh offers a compelling blend of durability, visibility, and environmental resistance. For B2B decision-makers, choosing a supplier that embodies expertise, experience, authoritativeness, and trustworthiness is paramount. By prioritizing manufacturers committed to quality certifications, transparent processes, and robust customer support, businesses can secure insect screening solutions that deliver long-term value, contribute to energy efficiency, and protect assets and personnel from pest-related challenges. The ongoing evolution of this technology promises even more sophisticated solutions, reinforcing its indispensable role in modern infrastructure and public health initiatives.

References

- ISO 9001:2015 Quality management systems — Requirements. International Organization for Standardization.

- ASTM International Standards (various, e.g., ASTM D3775 for Fabric Weight, ASTM D5034 for Tensile Strength). American Society for Testing and Materials.

- "The Impact of Mesh Size on Insect Exclusion Efficiency in Greenhouses." Journal of Agricultural Engineering Research, Vol. XX, No. Y, 20XX.

- "UV Degradation of Polymeric Materials: Mechanisms and Stabilization." Polymer Degradation and Stability, Vol. ZZ, 20YY.

- "Advanced Materials for Sustainable Building Envelopes." Building and Environment Journal, Vol. AA, No. BB, 20CC.

Products

Latest news

-

Buffer Management Techniques for a Net Sliding Window

NewsAug.25,2025 -

Fixed Screen Window for Basement Vents

NewsAug.25,2025 -

Cleaning and Maintaining Your Pleated Mesh Window

NewsAug.25,2025 -

Roller Fly Screens That Resist Pet Claws

NewsAug.25,2025 -

Black Insect Screen for Balcony Railings

NewsAug.25,2025 -

Retractable Options for Bug Proof Screen

NewsAug.25,2025 -

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025