Aug . 18, 2025 04:40 Back to list

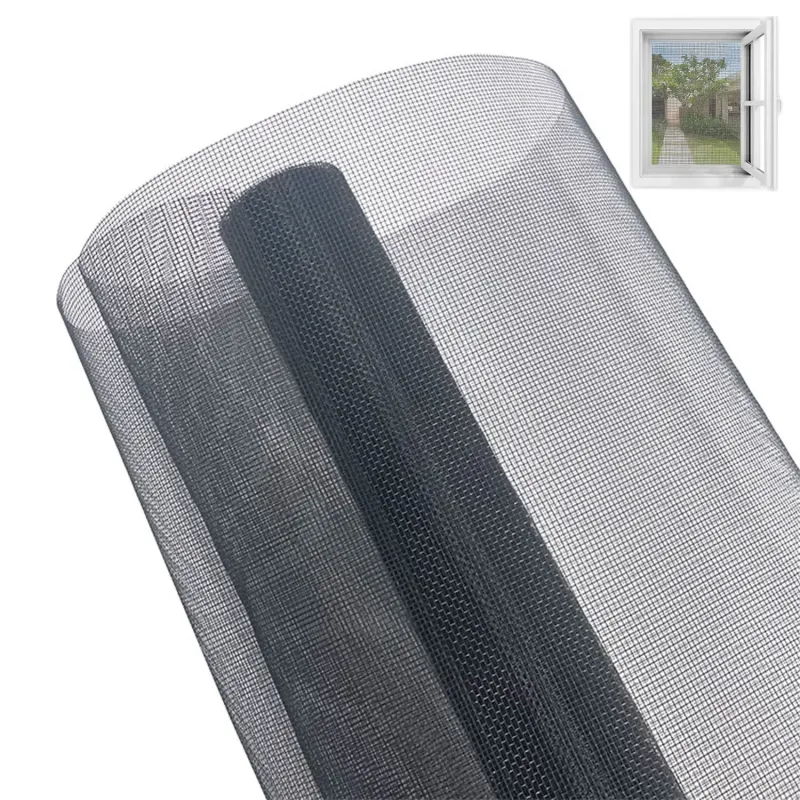

Durable Black Fly Screen Mesh – Ultimate Insect Protection

Understanding black fly screen mesh: An Essential Component in Modern Filtration and Protection Systems

In diverse industrial and domestic applications, the integrity of a protective barrier is paramount, and this is where advanced materials like black fly screen mesh, also known as black insect mesh, demonstrate their critical importance. This specialized mesh, meticulously engineered for durability and efficiency, serves as a cornerstone in preventing the ingress of unwanted pests and particulate matter while ensuring optimal airflow and visibility. Its unique black pigmentation not only enhances its aesthetic appeal in various settings but also contributes to better visibility by reducing glare, making it a preferred choice over lighter alternatives in specific scenarios. The manufacturing precision involved in creating such high-performance screens ensures uniform aperture sizes, crucial for consistent filtration and barrier efficacy. From agricultural ventilation systems to sophisticated industrial filtration processes, the demand for reliable and robust screen solutions continues to escalate, driving innovations in material science and weaving technologies. The versatility of black fly screen mesh extends beyond simple insect exclusion, encompassing applications that demand resistance to environmental stressors, chemical compatibility, and long-term structural stability, making it an indispensable asset in modern infrastructure development and maintenance. The growing global emphasis on sustainable and energy-efficient building practices further accentuates the value of high-quality screening solutions that reduce reliance on chemical pest control and improve indoor air quality.

The selection of the appropriate black fly screen mesh hinges on a comprehensive understanding of its material composition, weave patterns, and the specific environmental conditions it will encounter. Factors such as UV radiation exposure, chemical corrosive agents, temperature fluctuations, and mechanical stresses all play a vital role in determining the longevity and performance of the mesh. For instance, in coastal regions, a mesh with superior anti-corrosion properties is indispensable, while in agricultural settings, resistance to pesticides and fertilizers is equally critical. Furthermore, the advancements in polymer science have led to the development of meshes with enhanced tear resistance and dimensional stability, ensuring that they maintain their structural integrity even under demanding operational parameters. This continuous evolution in material technology allows manufacturers to offer customized solutions that meet stringent industry standards and client-specific requirements, moving beyond generic products to tailored high-performance barriers. Our expertise at CR Screen, reflected in our premium "Gray Insect Screen" line, underscores our commitment to delivering solutions that not only meet but exceed these evolving demands, providing unparalleled protection and peace of mind for B2B clients across diverse sectors. The careful consideration of mesh density, thread diameter, and open area percentage is crucial for optimizing airflow, light transmission, and filtration capabilities, ensuring that each application benefits from a precisely engineered solution that delivers superior performance.

The Meticulous Manufacturing Process of Advanced Insect Screen Mesh

The production of high-quality insect screen mesh, including the specialized black fly screen mesh, is a multi-stage, precision-driven process that begins with the selection of premium raw materials. Typically, fiberglass yarn coated with PVC (polyvinyl chloride) is the material of choice due to its exceptional balance of strength, flexibility, fire resistance, and resistance to environmental degradation. The manufacturing journey commences with the preparation of fiberglass filaments, which are then meticulously extruded and coated with a durable PVC layer. This coating process is critical as it imparts the mesh with its characteristic color, UV stability, and resistance to harsh weather conditions, preventing fraying and ensuring long-term performance. For instance, the "Gray Insect Screen" produced by CR Screen utilizes a specific PVC compound engineered for optimal outdoor longevity and resistance to common airborne pollutants. Following the extrusion and coating, these individual filaments are spooled, preparing them for the weaving stage. The quality of the raw material directly influences the final product's durability and effectiveness, necessitating stringent incoming material inspections to ensure compliance with international standards such as ISO 9001. This initial phase sets the foundation for a product that can withstand the rigors of various application environments, from temperate climates to extreme conditions. The uniformity of the PVC coating also plays a significant role in determining the mesh's aesthetic consistency and its ability to resist mold and mildew growth over time, which is particularly important in humid environments.

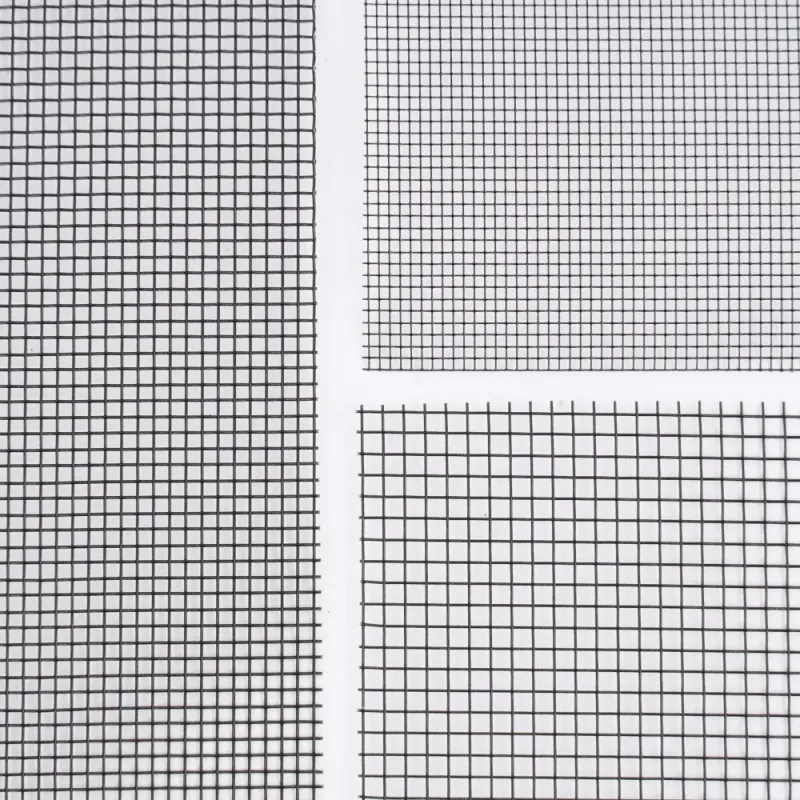

The core of insect screen manufacturing lies in the weaving process, where coated fiberglass yarns are interwoven to form the mesh structure. This typically involves advanced warp and weft weaving machinery that operates with extreme precision to maintain consistent aperture sizes and thread counts. The weaving technique, often plain weave, ensures maximum stability and uniform tension across the entire roll of mesh, which is vital for preventing sagging or distortion during installation and use. After weaving, the mesh undergoes a heat-setting process, where it is subjected to controlled temperatures to stabilize its dimensions, remove any residual stresses, and enhance its resistance to deformation. This thermal treatment is crucial for achieving the desired dimensional stability and preventing shrinkage or expansion under varying environmental conditions. Subsequently, the mesh may undergo further finishing treatments, such as additional coating applications to boost specific properties like enhanced fire retardancy or antimicrobial resistance. Throughout these stages, rigorous quality control checks are implemented, including visual inspections for defects, precise measurements of mesh count and wire diameter, and tensile strength tests to ensure the product meets or exceeds established industry standards like ASTM D4028 for fiberglass mesh or ANSI/SMA 1201-04 for window screen specifications. The integration of continuous monitoring systems ensures that any deviation from the specified parameters is immediately identified and corrected, guaranteeing a consistently high-quality final product.

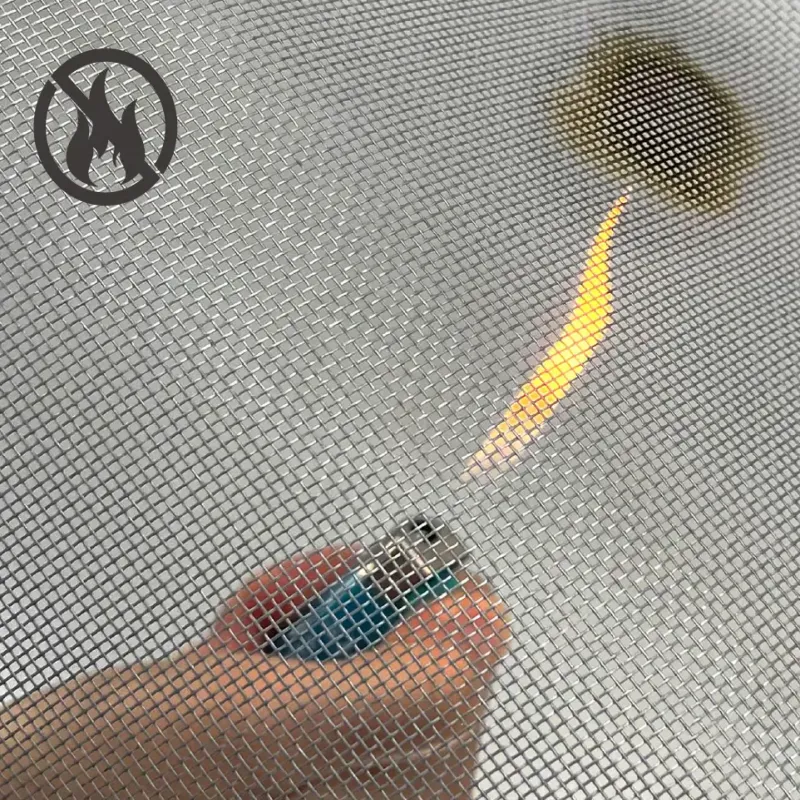

The final phase of the manufacturing process for products like black insect mesh involves extensive quality assurance and packaging. Post-treatment, the large rolls of mesh are meticulously inspected for any remaining imperfections, including inconsistencies in weave, coating irregularities, or damage. Automated inspection systems, often employing optical sensors, are used to detect even minute flaws, ensuring that only flawless products proceed to the next stage. Performance tests are conducted, including fire rating tests (e.g., NFPA 701, UL 94), UV degradation resistance tests (accelerated weathering), and chemical resistance evaluations, particularly for specialized applications in industries such as petrochemical and water treatment. These tests certify the mesh's suitability for various demanding environments, confirming its expected lifespan and operational integrity. Once certified, the mesh is carefully cut into specified widths and lengths, then packaged securely to prevent damage during transit and storage. For example, our "Gray Insect Screen" is often rolled onto robust core tubes and shrink-wrapped, then placed in durable cartons or crates, prepared for global distribution. This comprehensive quality control regimen, from raw material sourcing to final packaging, is indicative of a manufacturer's commitment to delivering a reliable, high-performance product that can meet the stringent demands of B2B clients, ensuring maximum customer satisfaction and product trust.

Technical Parameters and Performance Data for Black Fly Screen Mesh

The efficacy and suitability of black fly screen mesh are quantitatively defined by a range of critical technical parameters that guide its selection for specific applications. These parameters ensure that the mesh provides optimal performance in terms of pest exclusion, airflow, and durability. Key specifications include mesh count (the number of threads per inch in both warp and weft directions), wire diameter (the thickness of the individual fiberglass strands), and the resulting open area percentage, which dictates air permeability and visibility. For example, a standard 18x16 mesh count signifies 18 strands per inch in one direction and 16 in the perpendicular direction, providing an optimal balance for common insect protection. The wire diameter is crucial for determining the mesh's strength and rigidity, impacting its resistance to tearing and sagging under tension. A larger wire diameter generally implies greater strength but can slightly reduce the open area. Manufacturers also specify tensile strength and burst strength, measured in PSI or N/mm², which indicate the mesh's resistance to stretching and rupture, vital for applications where the mesh might be subjected to mechanical stress or high winds. Furthermore, UV resistance is quantified by accelerated weathering tests, such as those conducted under ASTM G154 or G155 standards, measuring color fade and degradation over simulated prolonged sun exposure. Fire retardancy is another critical parameter, often conforming to UL 94 V-0 or NFPA 701, especially for commercial and public building applications. The understanding and comparison of these parameters are indispensable for engineers and procurement specialists in making informed decisions for their projects, ensuring alignment with performance requirements and safety regulations.

| Parameter | Standard Value / Range | Measurement Unit | Significance |

|---|---|---|---|

| Material | Fiberglass yarn, PVC coated | N/A | Base material for strength, durability, and resistance. |

| Mesh Count (Warp x Weft) | 18x16, 20x20, 18x14 | Strands per inch (SPI) | Determines insect exclusion size and airflow. |

| Wire Diameter | 0.011 - 0.013 | Inches (in) | Influences strength, rigidity, and open area. |

| Open Area Percentage | Approx. 60-70% | % | Airflow, light transmission, and visibility. |

| Weight | 90 - 120 | g/m² | Indicator of material density and robustness. |

| Tensile Strength (Warp/Weft) | Min. 350 / 300 | N/5cm | Resistance to pulling forces before breaking. |

| UV Resistance | Excellent (Retains >80% strength after 2000hrs UV) | Hours (ASTM G154/G155) | Longevity under direct sunlight exposure. |

| Fire Retardancy | Self-extinguishing (UL 94 V-0 or NFPA 701) | Standard Compliance | Safety property, critical for building codes. |

| Operating Temperature Range | -30°C to +80°C | Degrees Celsius (°C) | Limits of thermal stability without degradation. |

| Chemical Resistance | Resistant to mild acids, alkalis, oils | N/A | Suitability for various industrial environments. |

The detailed understanding of these technical specifications allows for the precise customization of black insect mesh solutions to meet unique operational demands. For instance, in applications requiring enhanced airflow with minimal compromise on insect protection, a mesh with a higher open area percentage and precise mesh count like 20x20 may be specified, ensuring efficient ventilation without allowing the entry of smaller insects such as gnats or no-see-ums. Conversely, in areas prone to high winds or requiring increased security, a mesh with a larger wire diameter and superior tensile strength would be preferred to prevent tearing or blowouts. Furthermore, the longevity of these screens, often exceeding 10-15 years under normal conditions, translates into significant long-term cost savings for businesses by reducing the frequency of replacement and maintenance. This extended service life is a direct result of the high-quality materials and rigorous manufacturing processes, including the robust PVC coating that protects the fiberglass core from environmental degradation. For B2B stakeholders, these performance metrics are not merely numbers; they represent tangible benefits in terms of operational efficiency, safety compliance, and reduced total cost of ownership, making the investment in high-grade mesh a strategic decision for sustainable infrastructure and industrial processes. The integration of advanced materials science with precise weaving technology ensures that these meshes deliver consistent, reliable performance across their entire lifespan, even in the most demanding industrial settings.

Versatile Applications and Tangible Advantages of Black Fly Screen Mesh

The adaptability of black fly screen mesh makes it an invaluable asset across a multitude of industries, extending far beyond simple residential window screens. In the petrochemical industry, for instance, these meshes are critical for ventilation systems in control rooms and hazardous material storage areas, preventing insect ingress that could compromise sensitive equipment or create unsafe conditions, all while ensuring proper airflow to dissipate fumes. Their inherent resistance to chemical degradation, imparted by the robust PVC coating, is paramount in such corrosive environments. In metallurgy, black insect mesh is used in industrial filtration systems to prevent large particulate matter from entering machinery or ventilation ducts, thereby protecting equipment and maintaining air quality within foundries and processing plants. The mesh's ability to withstand high temperatures for brief periods and its robust construction contribute to its efficacy in these demanding settings. For water supply and drainage systems, specialized meshes act as primary filters to prevent debris, leaves, and larger aquatic organisms from clogging pipes, pumps, and treatment facilities, ensuring uninterrupted flow and reducing maintenance overhead. Here, the non-corrosive properties and structural integrity of fiberglass mesh are particularly beneficial for prolonged immersion or exposure to varying water chemistries. These diverse applications underscore the mesh's role not just as a barrier, but as an integral component in maintaining operational efficiency, safety, and environmental compliance within complex industrial ecosystems. The aesthetic benefit of black mesh, which offers superior outward visibility by absorbing more light and reducing glare compared to lighter meshes, also makes it a preferred choice in architectural designs where both functionality and visual appeal are critical.

Beyond industry-specific roles, the technical advantages of high-quality black insect mesh translate into significant operational benefits. One primary advantage is its contribution to energy savings. By effectively excluding insects and larger debris, these meshes allow for the continuous, unobstructed operation of ventilation and air conditioning systems, reducing the strain on HVAC units and optimizing their energy consumption. This is particularly relevant in commercial buildings and industrial facilities where climate control is critical, and blocked airflow can lead to increased energy expenditure. Secondly, the superior corrosion resistance of PVC-coated fiberglass mesh is a standout feature. Unlike metallic screens that can rust or degrade in humid or chemically aggressive environments, fiberglass mesh maintains its structural integrity and aesthetic appeal over extended periods, minimizing the need for costly replacements and repairs. This inherent resistance makes it ideal for coastal regions, industrial zones with corrosive atmospheres, or agricultural settings where exposure to fertilizers and pesticides is common. Furthermore, the inherent strength and flexibility of the material ensure that the mesh resists tearing, denting, and unraveling, even when subjected to moderate physical impact or continuous tension. The ease of installation and relatively low maintenance requirements further enhance its appeal, making it a cost-effective solution in the long run. These collective benefits underscore why a strategic investment in high-grade black fly screen mesh provides a robust return through enhanced operational efficiency, reduced maintenance costs, and improved environmental control across diverse commercial and industrial applications.

Custom Solutions and Industry Expertise: Why Choose CR Screen

Selecting the right supplier for black fly screen mesh is as crucial as understanding the product itself. Reputable manufacturers, like CR Screen, distinguish themselves through a combination of extensive industry experience, adherence to rigorous quality standards, and a robust capability for delivering custom solutions. With over a decade of dedicated service in the mesh screen industry, CR Screen has accumulated invaluable expertise in material science, manufacturing processes, and diverse application requirements. This depth of knowledge allows us to not only provide standard mesh products but also to engineer bespoke solutions tailored to unique project specifications. For instance, if a client requires a mesh with specific fire-retardant properties exceeding standard ratings for a high-risk industrial setting, or a unique mesh count to filter very specific particulate sizes, our R&D team can collaborate to develop and produce a specialized variant. This commitment to customization ensures that our B2B partners receive a product that precisely fits their needs, avoiding compromises that could lead to suboptimal performance or increased operational costs. Our established manufacturing facilities are equipped with state-of-the-art machinery and operated by skilled technicians, ensuring consistent quality and efficient production volumes capable of meeting large-scale industrial demands while maintaining the precision required for specialized orders. This holistic approach to client service and product development solidifies our position as a trusted partner in the global supply chain for advanced screening solutions.

Our dedication to quality and reliability is further evidenced by our comprehensive certification portfolio. CR Screen's manufacturing processes are certified under ISO 9001:2015, an internationally recognized standard for quality management systems, ensuring that every stage of production, from raw material sourcing to final packaging, adheres to the highest levels of quality control and continuous improvement. This certification provides our clients with assurance that products like our "Gray Insect Screen" are consistently produced to exacting specifications. Furthermore, our products undergo independent testing to comply with various industry-specific standards, including those related to UV resistance (e.g., ASTM standards), fire retardancy (e.g., NFPA 701, UL 94), and material safety (e.g., REACH, RoHS compliance where applicable), making them suitable for diverse regulatory environments globally. We have fostered strong, long-term partnerships with leading construction companies, industrial integrators, and agricultural enterprises worldwide, demonstrating our capability to support large-scale projects and consistently deliver on commitments. These partnerships are built on a foundation of trust, transparency, and a proven track record of product performance and reliable supply chain management. Our commitment to environmental responsibility is also reflected in our production processes, striving for minimal waste and energy consumption, further enhancing our appeal to companies with strong sustainability mandates.

Trustworthiness and Support: Our Commitment to Clients

Building and maintaining trust with B2B clients is paramount, especially when dealing with critical components like black insect mesh that impact operational efficiency and safety. At CR Screen, we prioritize transparency and robust customer support to ensure complete client satisfaction. Our Frequently Asked Questions (FAQ) section, accessible through direct consultation with our technical sales team, addresses common inquiries regarding product specifications, installation guidelines, maintenance, and material compatibility. This proactive approach helps clients quickly find answers and make informed decisions, minimizing potential delays or misunderstandings during project planning and execution. We provide clear and predictable delivery schedules, leveraging an optimized logistics network to ensure timely dispatch and arrival of orders, regardless of size or destination. Our typical delivery window is communicated upfront, taking into account order volume, customization requirements, and current production capacity, thereby enabling clients to manage their project timelines effectively and avoid costly disruptions due to material delays. For complex orders or large-scale projects, we offer dedicated project management support, including regular updates on production status and shipping milestones. This commitment to reliable delivery is a testament to our streamlined operations and our understanding of the critical nature of supply chain predictability for industrial clients.

Furthermore, our unwavering commitment to product quality is backed by a comprehensive warranty program. All our black fly screen mesh products, including the "Gray Insect Screen" series, come with a standard warranty covering material defects and manufacturing flaws for a specified period, typically ranging from 5 to 10 years depending on the product line and application. This warranty provides clients with peace of mind, knowing that their investment is protected and that CR Screen stands behind the durability and performance of its products. In the rare event of a product issue, our dedicated customer support team is readily available to provide prompt assistance, troubleshooting, and resolution, ensuring minimal downtime or inconvenience for our clients. We offer multi-channel support, including direct phone lines, email support, and online inquiry forms, ensuring that clients can reach us through their preferred method. Beyond problem resolution, our technical support extends to offering expert advice on product selection, application best practices, and custom solution development, providing ongoing value to our partners. This holistic approach to client support, from pre-sales consultation to post-delivery assistance and warranty coverage, underscores our dedication to fostering long-term, mutually beneficial relationships based on trust and consistent performance, solidifying our reputation as a reliable and customer-centric mesh solutions provider.

Industry Trends and Future Outlook for Insect Screen Technologies

The landscape of insect screen technologies, particularly for materials like black fly screen mesh, is continually evolving, driven by advancements in material science, environmental concerns, and shifting consumer and industrial demands. A significant trend is the increasing demand for eco-friendly and sustainable screening solutions. Manufacturers are exploring biodegradable polymers and advanced recycling methods for synthetic meshes to reduce their environmental footprint without compromising performance. This includes developing meshes with lower volatile organic compound (VOC) emissions during manufacturing and products that are more easily recyclable at the end of their long life cycles. Another emerging trend is the integration of smart technologies into screening solutions. This could involve meshes with integrated sensors that monitor air quality, detect insect presence, or even self-repair minor tears, offering unprecedented levels of protection and maintenance efficiency for critical infrastructure. While still in nascent stages for common insect screens, these advancements are indicative of a future where mesh provides far more than just a physical barrier. Furthermore, there is a growing emphasis on enhanced multi-functional properties, such as meshes that combine insect protection with improved thermal insulation, sound dampening, or even electromagnetic interference (EMI) shielding for highly sensitive electronic environments. These innovations aim to offer comprehensive solutions that address multiple challenges simultaneously, increasing the value proposition of advanced screening materials in diverse sectors.

The drive for higher performance and greater efficiency also fuels research into novel coating technologies for black insect mesh. These coatings are designed to impart specialized properties such as anti-microbial surfaces to prevent mold and bacterial growth, anti-dust properties to reduce maintenance, or hydrophobic surfaces that repel water and resist staining, which is particularly beneficial in regions with high humidity or frequent rainfall. The miniaturization of insects and the emergence of new pest species also necessitate the development of meshes with even finer apertures and higher mesh counts, ensuring effective exclusion without unduly compromising airflow or visibility. This technological push is vital for agricultural applications where even tiny pests can decimate crops, and for public health initiatives aimed at controlling vector-borne diseases. The market for high-performance screening solutions is also expanding globally, driven by urbanization, increased industrialization in developing economies, and a growing awareness of indoor air quality and pest control. This expanding market fuels investment in research and development, fostering an environment of continuous innovation to meet the complex and evolving needs of industrial and commercial clients worldwide. As a leader in this field, CR Screen remains at the forefront of these developments, continuously investing in R&D to bring cutting-edge, high-performance mesh solutions to the market that anticipate future industry demands and challenges.

References

- ASTM D4028, "Standard Specification for Woven Fiberglass Fabric for Window Screens." ASTM International.

- ISO 9001:2015, "Quality Management Systems – Requirements." International Organization for Standardization.

- NFPA 701, "Standard Methods of Fire Tests for Flame Propagation of Textiles and Films." National Fire Protection Association.

- UL 94, "Tests for Flammability of Plastic Materials for Parts in Devices and Appliances." Underwriters Laboratories.

- ANSI/SMA 1201-04, "Specifications for Window Screens." Screen Manufacturers Association.

This is the first article

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025