The Enduring Value of Fixed Screen Doors in Modern Infrastructure

In the evolving landscape of industrial, commercial, and residential infrastructure, the demand for robust, reliable, and efficient environmental control solutions has never been higher. Among the myriad options, the

fixed screen door stands out as a fundamental component, offering an unparalleled blend of ventilation, pest deterrence, and security. Unlike retractable or hinged alternatives, the intrinsic design of a fixed screen door provides a permanent barrier, making it ideal for high-traffic areas or environments where consistent protection is paramount. This robust solution addresses a critical need in various sectors, from food processing facilities requiring stringent hygiene standards to chemical plants where controlled airflow and prevention of contaminant ingress are vital. The market trend indicates a clear shift towards solutions that offer long-term durability, minimal maintenance, and superior performance under diverse environmental conditions. As industries continue to prioritize operational efficiency and worker safety, the strategic integration of well-engineered fixed door fly screens becomes indispensable. These systems are not merely barriers but active contributors to maintaining indoor air quality, reducing cooling costs by facilitating natural ventilation, and enhancing overall occupational well-being.

The technological advancements in materials science and manufacturing processes have significantly elevated the capabilities of modern fixed screen door systems. Contemporary designs incorporate high-strength alloys, advanced mesh materials, and sophisticated coating technologies to extend lifespan and enhance performance. For instance, the use of marine-grade stainless steel mesh combined with powder-coated aluminum frames ensures resistance to extreme weather, corrosive atmospheres, and persistent UV exposure. This resilience is critical in applications ranging from coastal residential properties battling salt air to industrial complexes exposed to harsh chemicals. Furthermore, the integration of specialized mesh types, such as those with finer weaves or reinforced strands, allows for tailored solutions against specific pest threats, including smaller insects or even airborne debris. The focus on sustainability also drives innovation, with manufacturers exploring recyclable materials and energy-efficient production methods. This holistic approach ensures that a fixed screen door not only fulfills its primary function but also aligns with broader environmental and economic objectives, offering a sustainable and cost-effective barrier solution that meets the rigorous demands of 21st-century infrastructure. The persistent threat of vector-borne diseases also underlines the importance of effective mosquito door frame solutions, making fixed screens a crucial public health component in many climates.

In-Depth Technical Specifications and Performance Parameters

Understanding the technical specifications of a fixed screen door is paramount for procurement specialists and engineers to ensure optimal performance and longevity in specific application environments. Key parameters include frame material, mesh composition, mesh count, opening size, and surface finish. Common frame materials include extruded aluminum, known for its lightweight nature, excellent corrosion resistance, and ease of fabrication, often anodized or powder-coated for enhanced durability and aesthetics. Stainless steel (e.g., 304 or 316 grade) is chosen for its superior strength and resistance to harsh chemicals or saltwater environments, making it ideal for marine or industrial chemical processing applications. The mesh itself is typically fabricated from fiberglass (PVC-coated for UV stability and durability), aluminum, or stainless steel wire. Fiberglass is cost-effective and resilient against impacts, while stainless steel offers maximum strength against punctures and gnawing pests, crucial for security or vermin control in sensitive areas like food preparation facilities. The mesh count, expressed as strands per inch (e.g., 18x14 or 20x20), dictates the fineness of the screen and its effectiveness against various insect sizes. A higher mesh count implies smaller openings, offering better protection against tiny gnats or no-see-ums, albeit with a slight reduction in airflow.

Furthermore, the performance of a fixed screen door is quantified by several critical metrics beyond material composition. These include wind load resistance, thermal expansion coefficients, and flammability ratings. For instance, in regions prone to high winds or cyclonic activity, the structural integrity of the frame and the secure attachment of the mesh are evaluated against stringent wind load standards, often specified in pounds per square foot (PSF) or Pascal (Pa). Thermal expansion, while often overlooked, is crucial for large installations or applications in environments with significant temperature fluctuations, as it dictates how materials expand and contract, affecting the long-term integrity of the frame and mesh tension. Compliance with fire safety regulations, indicated by flammability ratings, is also essential, particularly for commercial and public buildings. Manufacturers adhere to international standards such as ISO (International Organization for Standardization) for quality management systems and ANSI (American National Standards Institute) for product performance specifications, ensuring consistent quality and predictable performance. For specialized applications like cleanrooms, mesh materials might undergo specific treatments or certifications, such as those related to particle shedding or anti-microbial properties, ensuring that the fixed door fly screens meet the exacting demands of controlled environments.

Typical Fixed Screen Door Technical Parameters

| Parameter |

Description |

Typical Values/Standards |

| Frame Material |

Structural integrity and corrosion resistance. |

Extruded Aluminum (6063-T5/T6), Stainless Steel (304/316) |

| Mesh Material |

Pest control, airflow, and durability. |

Fiberglass (PVC Coated), Aluminum, Stainless Steel (304/316L) |

| Mesh Count |

Density of mesh strands per inch. |

18x14, 20x20, 30x30 (for fine mesh) |

| Frame Finish |

Corrosion protection and aesthetics. |

Powder Coating (AAMA 2603/2604/2605), Anodizing (Class I/II) |

| Overall Dimensions |

Customizable to specific openings. |

Up to 4ft x 8ft (single panel), custom larger sizes possible |

| Wind Load Rating |

Resistance to wind pressure. |

Typically 60-120 PSF, per ASTM E330 |

| UV Stability |

Resistance to degradation from sunlight. |

Excellent (especially PVC-coated fiberglass) |

| Lifespan |

Expected operational life under normal conditions. |

10-25+ years, depending on materials & environment |

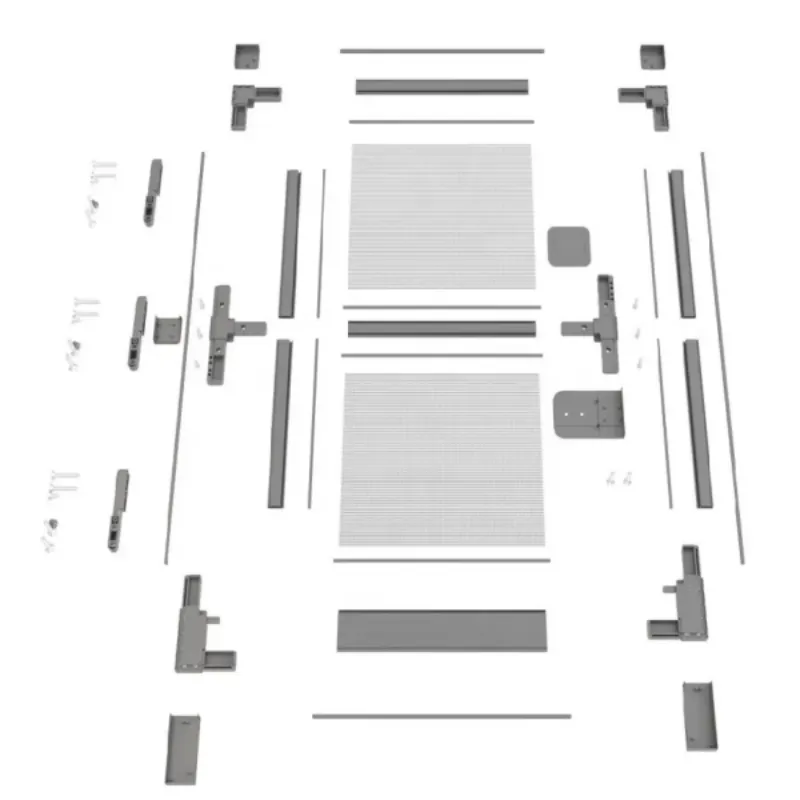

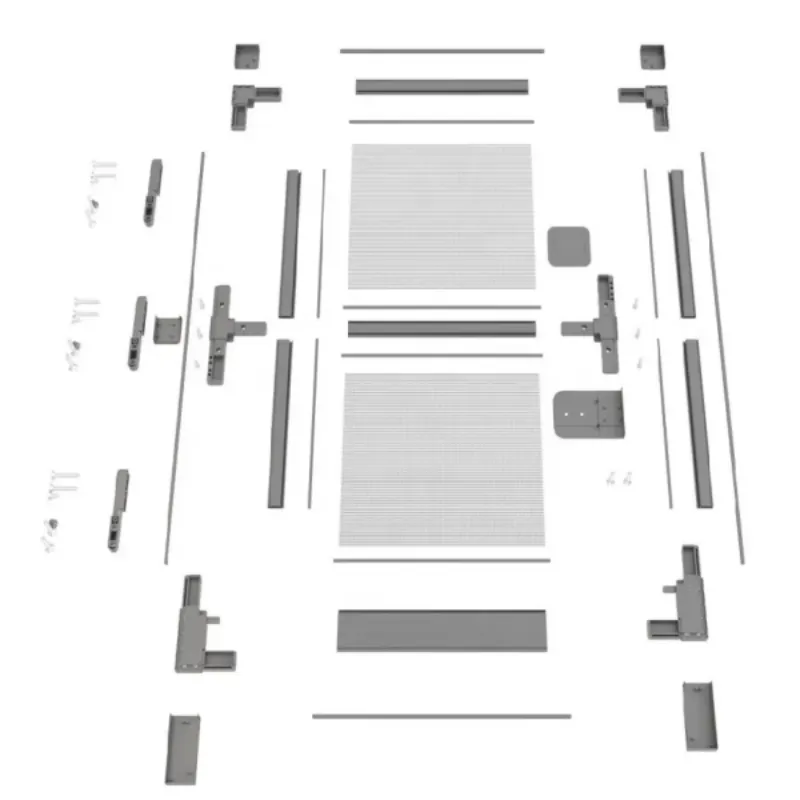

Precision Manufacturing Process: Crafting the Fixed Screen Door

The manufacturing of a high-quality fixed screen door is a multi-stage process that emphasizes precision, material integrity, and adherence to rigorous quality control protocols. It begins with the meticulous selection of raw materials, such as high-grade aluminum billets for extrusion or stainless steel sheets for fabrication. For aluminum frames, the process often involves extrusion, where heated aluminum is forced through a die to create the desired profile. This allows for complex, interlocking designs that enhance structural rigidity and simplify assembly. Subsequent stages include precise cutting of these profiles to specified dimensions, often utilizing CNC (Computer Numerical Control) machining to achieve tight tolerances and intricate details. This level of automation minimizes human error and ensures consistency across large production runs, which is critical for projects requiring numerous identical units. The corners of the frame are then typically joined using robust methods such as corner keys, often reinforced with internal fasteners or welding, depending on the material and desired strength. For stainless steel frames, processes like laser cutting and TIG welding are employed to create strong, seamless joints that resist corrosion and withstand significant operational stress.

Once the frame structure is complete, the surface treatment process is initiated. For aluminum frames, this commonly involves powder coating or anodizing. Powder coating applies a durable, protective layer that is resistant to chipping, scratching, and UV degradation, offering a wide range of aesthetic finishes. Anodizing, an electrochemical process, enhances the natural corrosion resistance of aluminum while creating a hard, porous surface that can be dyed for various colors. For stainless steel frames, passivation or electropolishing may be applied to remove surface contaminants and enhance corrosion resistance. Following surface treatment, the mesh material is precisely cut and securely integrated into the frame. This step is critical; methods include spline retention (where the mesh edge is pushed into a channel with a rubber spline), mechanical fastening (screws or clamps), or even welding for high-security applications using stainless steel mesh. Each fixed screen door undergoes stringent quality inspection, including dimensional checks, visual inspection for defects, and functional testing to ensure the mesh tension and frame integrity meet or exceed industry standards such as ISO 9001 for quality management and ANSI/SDI-100 for door performance. This comprehensive process guarantees a product with exceptional durability, a long service life of 15-25 years or more depending on environmental exposure, and reliable performance in industries like petrochemical (for corrosive environments), metallurgy (for dust and particulate control), and water supply/drainage (for insect and debris exclusion), demonstrating significant advantages in terms of anti-corrosion and energy efficiency by promoting natural ventilation.

Core Advantages and Diverse Application Scenarios

The inherent advantages of a fixed screen door extend beyond mere insect deterrence, contributing significantly to operational efficiency, building longevity, and occupant well-being across a diverse range of applications. Foremost among these is unparalleled durability and low maintenance. Unlike moving screen systems that can suffer from wear and tear on hinges, rollers, or retractable mechanisms, a fixed unit has fewer moving parts, drastically reducing the likelihood of mechanical failure and the need for frequent repairs. This translates into significant cost savings over the product's lifespan. Their robust construction, particularly when using high-grade materials like stainless steel frames and mesh, provides an added layer of security against unauthorized entry or tampering, making them suitable for critical infrastructure. The primary function of pest control is executed flawlessly, preventing insects, rodents, and other unwanted organisms from entering controlled environments, which is paramount in sectors like food processing, pharmaceuticals, and healthcare, where hygiene standards are non-negotiable. Furthermore, a fixed screen door promotes natural ventilation, allowing fresh air to circulate freely while keeping pests out. This reduces reliance on air conditioning, leading to substantial energy savings and lower carbon footprints, aligning with contemporary sustainability objectives.

The versatility of the fixed screen door allows for its seamless integration into various industrial and commercial settings. In the petrochemical industry, stainless steel fixed door fly screens are indispensable, providing corrosion resistance against harsh chemical fumes while allowing necessary airflow and preventing bird or insect ingress into sensitive areas. Similarly, in metallurgy, these screens protect personnel and equipment from airborne particulates and debris while facilitating ventilation in high-temperature environments. For water supply and drainage facilities, they serve as effective barriers against insects that could otherwise contaminate water sources or clog filtration systems. In the burgeoning controlled environment agriculture (CEA) sector, precise control over pest ingress is vital for crop health and yield, making specialized fixed screen door solutions a critical investment. Beyond industrial applications, these doors are increasingly prevalent in high-rise residential buildings, educational institutions, and healthcare facilities, where they offer quiet, energy-efficient ventilation and reliable pest protection without compromising aesthetic appeal. The ability to customize mesh types, frame finishes, and sizes ensures that a mosquito door frame solution can be tailored to meet the specific functional and aesthetic requirements of any project, from a sterile laboratory entrance to a grand public building.

Tailored Customization and Manufacturer Selection Guidelines

Recognizing that no two projects are identical, leading manufacturers of fixed screen door solutions offer extensive customization options to meet specific architectural, environmental, and security requirements. Customization typically encompasses dimensions, allowing for precise fitting into non-standard openings or integration with existing structures. Clients can specify frame materials (e.g., specific aluminum alloys, marine-grade stainless steel) and finishes (e.g., custom powder coating colors, anodized bronze) to match aesthetic designs or withstand particular environmental stressors. Mesh type is another critical customizable element, ranging from standard fiberglass for general pest control to high-strength stainless steel mesh for security or fine-weave mesh for protection against extremely small insects. For facilities requiring enhanced air filtration, specialized mesh materials with particulate filtering capabilities can be integrated. Beyond materials, optional features such as reinforced kick plates, pet-resistant mesh, or integrated security bars can be added to enhance functionality and durability. This bespoke approach ensures that each fixed screen door is optimized for its intended purpose, delivering maximum value and performance over its extensive operational lifespan.

Selecting the right manufacturer for fixed screen door solutions is as crucial as defining the product specifications. A reputable manufacturer distinguishes itself through several key attributes. Firstly, look for certifications such as ISO 9001 for quality management systems, which indicates a consistent commitment to quality control throughout the production process. Companies with a long service history and extensive experience in B2B markets often possess a deeper understanding of industrial demands and complex project requirements. Strong R&D capabilities are indicative of a manufacturer's commitment to innovation, offering cutting-edge materials and designs. Prioritize manufacturers who provide comprehensive pre-sales consultation, detailed technical specifications, and robust after-sales support, including installation guidance and warranty provisions. Transparent communication regarding delivery cycles and logistical support for international shipments is also vital for seamless project execution. Client testimonials, case studies, and a portfolio of successfully completed projects in similar industries can provide valuable insights into a manufacturer's reliability and product performance. Evaluating these factors rigorously ensures a partnership that delivers not only high-quality fixed door fly screens but also peace of mind throughout the project lifecycle, guaranteeing that the chosen mosquito door frame solutions are fit for purpose and built to last.

Real-World Application Cases and Commitment to Customer Trust

The practical effectiveness of a fixed screen door is best illustrated through its application in diverse real-world scenarios, where it consistently addresses critical operational challenges. Consider a large-scale food processing plant that required stringent insect control at all entry and exit points to comply with HACCP (Hazard Analysis and Critical Control Points) regulations. By installing custom-fabricated stainless steel fixed screen door units with a fine mesh count (e.g., 20x20), the plant achieved near-zero insect ingress while maintaining optimal ventilation for its internal environment, contributing to improved product safety and reduced energy consumption from HVAC systems. Another notable case involves a chemical storage facility where corrosive fumes necessitated highly resilient access solutions. Here, fixed screens with marine-grade aluminum frames and specialized powder coatings were deployed, demonstrating exceptional resistance to corrosion and an extended lifespan in a notoriously harsh environment, outperforming traditional solutions that would degrade rapidly. In a high-traffic distribution center, heavy-duty fixed screens were installed at loading dock entrances to deter birds and large insects while allowing consistent airflow, significantly enhancing workplace comfort and hygiene for warehouse personnel. These cases underscore the adaptability and indispensable role of robust fixed door fly screens in maintaining operational integrity across various demanding sectors.

Building and maintaining customer trust is paramount in the B2B sector, and this is achieved not only through superior product quality but also through comprehensive service and unwavering commitment. Manufacturers offer a clearly defined delivery cycle, ensuring that project timelines are met with precision and reliability. Standard products often have shorter lead times, while custom solutions are meticulously scheduled with transparent communication regarding production and shipping stages. Quality assurance is integrated into every phase of the manufacturing process, from raw material inspection to final product testing, often backed by independent third-party certifications like TÜV or SGS. A robust warranty commitment, typically ranging from 5 to 10 years on materials and workmanship, provides clients with long-term peace of mind, demonstrating confidence in the product's durability and performance. Beyond the sale, dedicated customer support channels, including technical assistance, maintenance guides, and responsive inquiry handling, ensure that clients receive ongoing support. This holistic approach, from initial consultation to post-installation service, fosters lasting partnerships. The implementation of a robust mosquito door frame solution with clear service level agreements signifies a manufacturer's dedication to operational excellence and client satisfaction, reinforcing confidence in their investment.

Frequently Asked Questions (FAQs) About Fixed Screen Doors

Q1: What are the primary advantages of a fixed screen door over a retractable or hinged screen?

A1: The main advantages of a fixed screen door include superior durability, minimal maintenance due to fewer moving parts, enhanced security (as they are permanently installed), and consistent performance in high-traffic or harsh environments. They offer a permanent barrier against pests and debris, and their robust construction makes them highly resistant to wear and tear compared to mechanisms that rely on sliding or folding components. This makes them ideal for commercial and industrial applications where reliability and longevity are critical.

Q2: How do I determine the right mesh material for my specific application?

A2: The choice of mesh material depends on your specific needs. Fiberglass mesh (PVC-coated) is a cost-effective, durable option for general pest control and good visibility. Aluminum mesh offers greater strength and fire resistance. Stainless steel mesh (304 or 316 grade) provides the highest level of durability, security, and corrosion resistance, making it suitable for industrial settings, coastal areas, or applications requiring protection against larger pests or vandalism. Fine mesh counts (e.g., 20x20) are recommended for very small insects like no-see-ums, while standard (18x14) is sufficient for most common insects. Consult with a manufacturer's technical team for tailored recommendations based on your environment and desired performance.

Q3: Can fixed screen door systems be customized for unusual door frame sizes or shapes?

A3: Yes, leading manufacturers offer extensive customization for fixed screen door systems. This includes custom dimensions for height and width to fit unique or non-standard door frames, as well as specific frame profiles or designs to integrate seamlessly with existing architectural elements. Additionally, customization extends to frame colors (via powder coating), specialized mesh types (e.g., pet-resistant, solar screening, security mesh), and additional features like kick plates or heavy-duty hardware. This ensures that a custom mosquito door frame solution can be engineered to precisely meet any project requirement.

Q4: What is the expected lifespan of a high-quality fixed screen door, and what maintenance is required?

A4: A high-quality fixed screen door, especially one made with durable materials like extruded aluminum or stainless steel frames and robust mesh, can have an expected lifespan of 15 to 25 years or even longer, depending on the material selection, environmental exposure, and quality of manufacturing. Maintenance is typically minimal: regular cleaning with mild soap and water to remove dirt and debris is usually sufficient to maintain appearance and functionality. For highly corrosive environments, periodic inspection for early signs of wear or corrosion, and prompt repair of any minor damage, can further extend its service life.

Conclusion and Authoritative References

The fixed screen door represents an indispensable asset in modern infrastructure, delivering multifaceted benefits that span pest control, energy efficiency, security, and long-term cost-effectiveness. Its robust construction and permanent installation make it a superior choice for environments demanding unwavering performance and minimal maintenance, from demanding industrial settings like petrochemical plants and metallurgical facilities to critical commercial spaces and residential developments. Through advanced manufacturing processes, precise material selection, and adherence to international quality standards such as ISO and ANSI, contemporary fixed screen solutions offer unparalleled durability and adaptability. The ability to customize every aspect, from frame material and finish to mesh type and dimensions, ensures that each fixed screen door is perfectly aligned with the unique requirements of diverse applications. As industries continue to seek sustainable, reliable, and high-performance solutions for environmental control and operational integrity, the strategic integration of meticulously engineered fixed door fly screens stands as a testament to their enduring value and technological sophistication. By choosing a reputable manufacturer committed to quality, innovation, and comprehensive customer support, businesses and developers can invest with confidence in solutions that contribute significantly to safety, efficiency, and comfort for decades to come.

References:

- American National Standards Institute (ANSI). (2023). Standards for Door and Hardware Products.

- International Organization for Standardization (ISO). (2023). ISO 9001: Quality Management Systems – Requirements.

- ASTM International. (2022). Standard Test Methods for Structural Performance of Exterior Windows, Doors, Skylights, and Curtain Walls by Uniform Static Air Pressure Difference (ASTM E330).

- National Fenestration Rating Council (NFRC). (2021). Product Certification and Rating Procedures.

- U.S. Department of Energy. (2020). Energy-Efficient Building Envelopes.