Ago . 15, 2025 04:20 Back to list

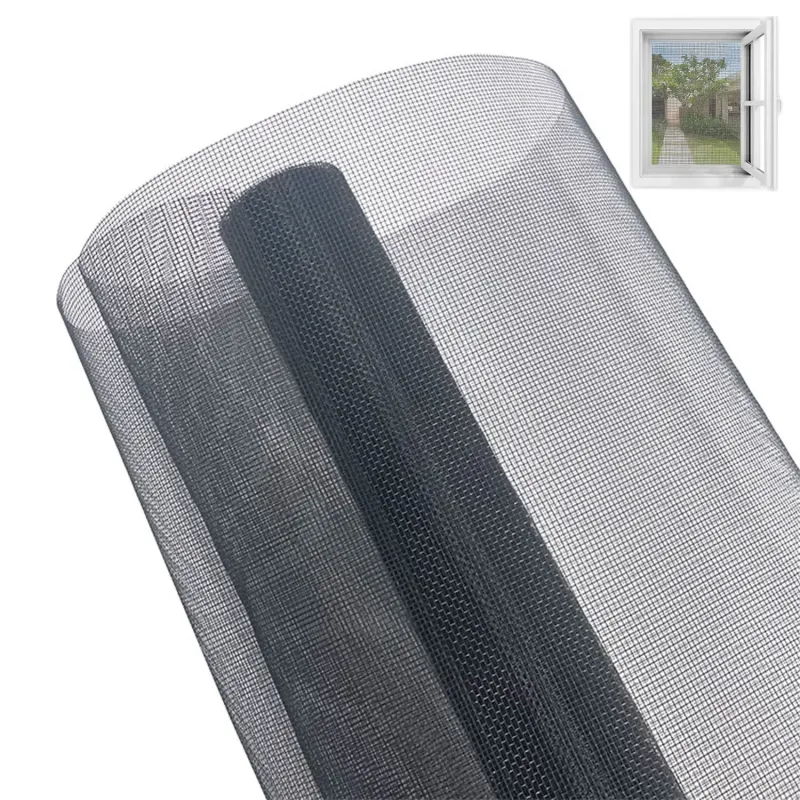

Durable Black Fly Screen Mesh | Effective Insect Barrier

The Strategic Imperative of Black Fly Screen Mesh in Modern Applications

In an increasingly interconnected world, effective pest control solutions are paramount for both public health and industrial integrity. Among the myriad of protective barriers, black fly screen mesh stands out as a critical component, offering superior defense against a wide spectrum of insects, including gnats, mosquitoes, and indeed, flies. This specialized mesh, often also referred to as black insect mesh, is engineered not just for physical exclusion but also for optimizing light transmission and maintaining aesthetic appeal in diverse settings. The market for such high-performance screening solutions is experiencing robust growth, driven by heightened environmental awareness, stringent health regulations, and the expansion of residential, commercial, and agricultural infrastructures. Businesses are increasingly seeking durable, long-lasting, and highly effective screening materials to safeguard their operations and assets from the persistent threats posed by insect infestations.

Current industry trends indicate a strong shift towards materials offering enhanced UV stability, greater tensile strength, and improved air permeability, without compromising on insect exclusion capabilities. Innovations in polymer science and weaving technologies are continuously pushing the boundaries of what these meshes can achieve, making them more resilient to environmental degradation and mechanical stress. The demand extends across various sectors, from residential window and door screens to large-scale agricultural netting for crop protection, and even specialized filtration in industrial ventilation systems. Understanding the nuanced technical specifications and application-specific advantages of black fly screen mesh is essential for procurement managers and engineers aiming to implement optimal, cost-effective pest control strategies that align with long-term operational sustainability.

Deciphering Black Fly Screen Mesh: Core Characteristics and Distinction

At its core, black fly screen mesh is a precisely woven material designed to prevent the entry of insects while allowing for adequate airflow and visibility. Its primary distinguishing feature is the small aperture size, which is specifically engineered to block even tiny gnats and flies, often smaller than standard mosquitoes. The "black" designation refers to its color, achieved through pigmentation during the manufacturing process, which offers several practical benefits. Black mesh tends to provide better outward visibility due to reduced glare, creating a clearer view from indoors. This optical property, combined with its effective insect barrier, makes it a preferred choice for residential and commercial applications where both functionality and aesthetic integration are crucial.

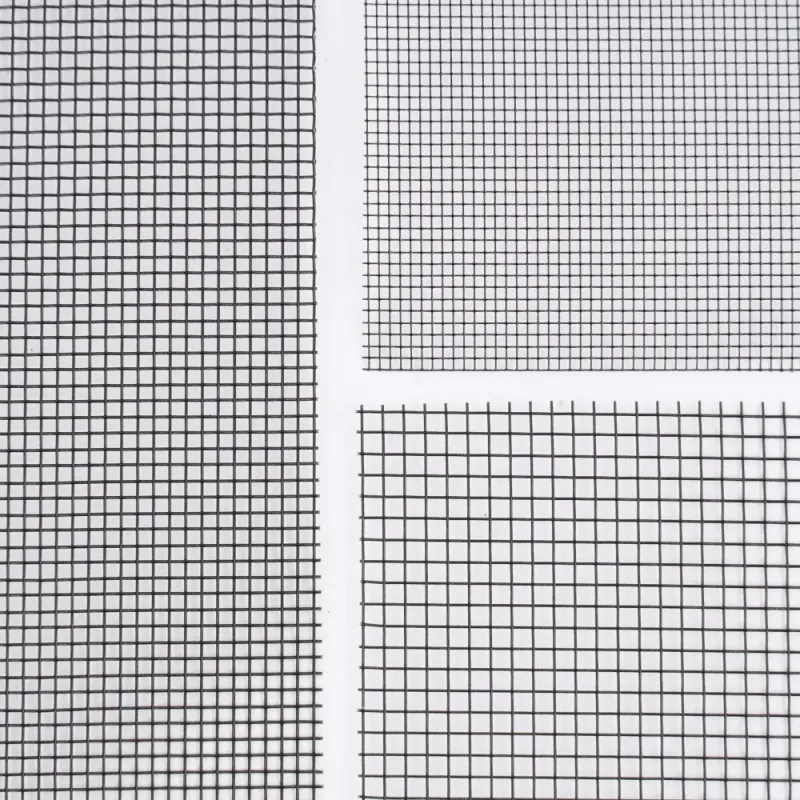

While closely related, the term black insect mesh is a broader category that encompasses various mesh sizes designed to exclude different types of insects. A black fly screen mesh is a specific type of black insect mesh optimized for smaller pests like flies and gnats. Key characteristics that define the performance of this mesh include its mesh count (threads per inch), wire diameter, material composition (typically fiberglass, polyester, or occasionally stainless steel), and the type of weave (plain weave being common). For instance, a typical 18x16 mesh count for standard insect screening might be insufficient for tiny flies, necessitating a finer 20x20 or even 30x30 mesh for effective black fly exclusion. Understanding these specifications is vital for selecting a product that delivers the intended level of protection and durability, especially when considering environmental factors like UV exposure and humidity.

The Meticulous Manufacturing Journey of Black Fly Screen Mesh

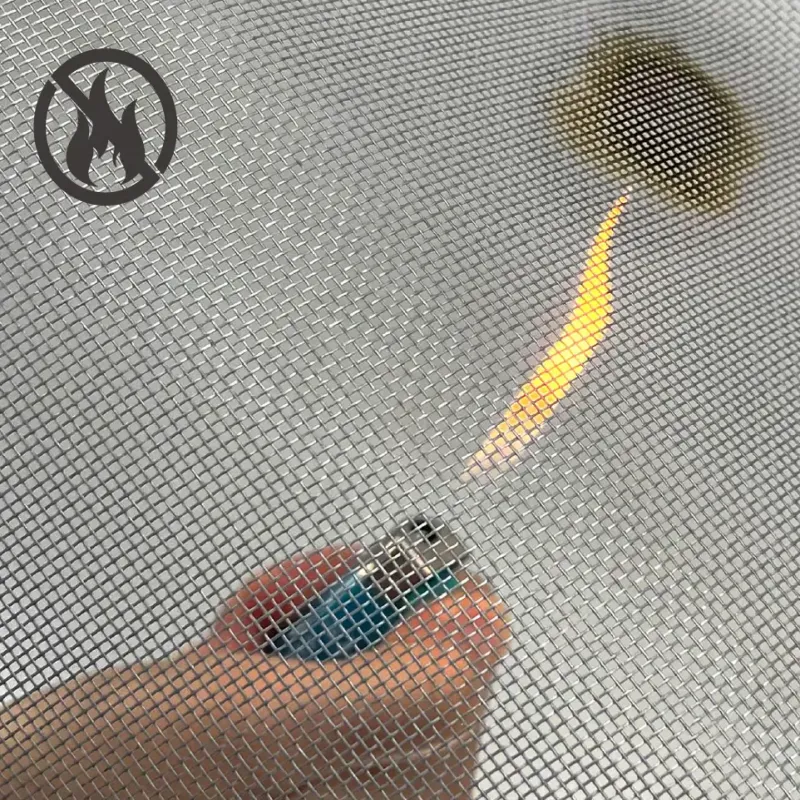

The production of high-quality black fly screen mesh involves a multi-stage, precision-driven manufacturing process, ensuring consistency in weave, aperture size, and material integrity. The journey typically begins with the selection of high-grade raw materials, predominantly fiberglass yarn coated with PVC, or robust polyester fibers for enhanced strength and UV resistance. For specialized industrial applications, materials like stainless steel or bronze may also be used, offering superior corrosion resistance and durability in harsh environments, such as those found in petrochemical or certain metallurgical facilities where robust filtration is required. These materials are chosen for their intrinsic properties, including tensile strength, fire retardancy, and resistance to environmental degradation like UV radiation and moisture.

The core manufacturing process for polymer-based mesh, such as fiberglass or polyester black fly screen mesh, often follows these steps:

- Yarn Preparation: Raw fiberglass strands are spun and coated with PVC resin, often pigmented black. Polyester yarns are similarly processed to achieve the desired filament diameter and strength.

- Weaving: The coated yarns are then fed into advanced weaving looms. These machines precisely interlace the warp (longitudinal) and weft (transverse) threads to create a uniform mesh pattern with a consistent aperture size, crucial for effective fly exclusion. The plain weave is most common for its stability and uniformity.

- Heat Setting/Curing: After weaving, the mesh undergoes a heat-setting process. For PVC-coated fiberglass, this cures the PVC, locking the weave in place, enhancing dimensional stability, and improving resistance to fraying. For polyester, it stabilizes the fabric, preventing stretching and shrinkage.

- Finishing: The mesh is then cleaned, inspected for defects, and often treated with additional coatings for enhanced UV resistance, anti-microbial properties, or improved stiffness, depending on the application.

- Slitting and Packaging: Finally, the broad mesh rolls are precisely slit into standard or custom widths and lengths, then carefully packaged for shipping to maintain product integrity.

Technical Specifications and Performance Parameters

Selecting the appropriate black fly screen mesh hinges on a precise understanding of its technical specifications. These parameters directly influence the mesh's effectiveness, durability, and suitability for specific applications. Key factors include mesh count, wire diameter, material composition, open area percentage, and UV resistance, all contributing to its performance against pests and environmental stressors. For instance, a higher mesh count indicates smaller apertures, crucial for excluding minute insects like gnats and no-see-ums, which are often more problematic than larger flies. The wire diameter, while impacting the mesh's strength and durability, also influences the overall open area and thus airflow and visibility.

| Parameter | Description | Typical Range (Fiberglass PVC Coated) | Impact on Performance |

|---|---|---|---|

| Material | Composition of fibers used in weaving. | Fiberglass (PVC Coated), Polyester, Stainless Steel, Aluminum | Durability, corrosion resistance, fire rating, cost. Fiberglass is common for balanced performance. |

| Mesh Count | Number of strands per linear inch (warp x weft). | 18x16, 20x20, 20x18, 24x24 (for finer mesh) | Determines insect exclusion capability. Higher count = smaller holes = better for gnats/small flies. |

| Wire Diameter | Thickness of individual mesh strands. | 0.009" to 0.013" (0.22mm - 0.33mm) | Impacts strength, durability, and open area. Thicker wire = stronger, but slightly less open area. |

| Open Area (%) | Percentage of total mesh area that is open space. | Approx. 60% - 70% (for 18x16 to 20x20 mesh) | Influences airflow, visibility, and light transmission. Higher % means more air/light. |

| UV Resistance | Ability to withstand degradation from ultraviolet radiation. | Excellent (stabilized PVC coating) | Crucial for outdoor longevity, preventing brittleness and color fading. |

| Tensile Strength | Resistance to breaking under tension (lbs/inch). | >40 lbs/in (Warp & Weft) | Indicates durability against tears, punctures, and stretching. |

| Fire Retardancy | Ability to resist ignition and slow flame spread. | Self-extinguishing (per ASTM E84 Class A/B) | Important for safety in residential and commercial buildings. |

Beyond these base parameters, specialized meshes may offer anti-microbial treatments, improved chemical resistance for industrial environments, or higher resistance to pet damage. CR Screen, for example, offers a range of high-performance insect screens, including the Gray Insect Screen, which exemplifies these advanced specifications. This meticulous approach to material science and engineering ensures that each roll of black insect mesh delivers optimal performance for its intended purpose, contributing to energy efficiency by reducing the need for chemical pest control and enhancing indoor air quality.

Unrivaled Advantages of Black Fly Screen Mesh

The adoption of black fly screen mesh offers a compelling suite of technical and operational advantages that extend beyond mere insect exclusion. One of its most significant benefits is its superior optical clarity and reduced glare. The black pigmentation absorbs more light, minimizing reflections and allowing for a clearer, unobstructed view from inside, which is particularly beneficial for large window installations, patios, and outdoor living spaces. This enhances the user experience, making the screen less noticeable and promoting a more open feel. Furthermore, the dark color provides a subtle level of privacy during daylight hours, as it is harder to see through from the outside.

From a performance standpoint, the material composition and precise weaving of this specialized mesh contribute to exceptional durability and longevity. High-quality fiberglass or polyester meshes are inherently resistant to common environmental stressors. They exhibit excellent UV stability, preventing the material from becoming brittle, cracking, or fading over extended periods of sun exposure—a common failure point for lesser quality screens. This resistance translates into a longer service life, reducing the need for frequent replacements and lowering overall maintenance costs for commercial properties and industrial facilities. Moreover, the robust construction provides good resistance to tears, punctures, and sagging, maintaining its integrity even under moderate physical stress or extreme weather conditions.

Beyond physical protection, the fine mesh count of black insect mesh ensures optimal airflow while effectively blocking even the smallest insects. This balance is crucial for maintaining comfortable indoor temperatures without relying solely on air conditioning, thereby contributing to energy savings. In agricultural settings, it safeguards valuable crops from insect-borne diseases without resorting to harmful pesticides, promoting sustainable farming practices. Its inherent corrosion resistance, especially in fiberglass and PVC-coated variants, makes it suitable for humid or coastal environments, including applications in areas like water treatment plants or facilities susceptible to high moisture. This combination of aesthetic, protective, and economic benefits positions black fly screen mesh as a highly advantageous solution across a broad spectrum of applications, enhancing both comfort and operational efficiency.

Diverse Application Scenarios of Black Fly Screen Mesh

The versatility and high performance of black fly screen mesh make it indispensable across a multitude of sectors, extending far beyond traditional residential window screens. Its primary role in residential and commercial buildings remains paramount, providing essential protection against a variety of insects while allowing for natural ventilation. From homes and apartments to restaurants, hotels, and office complexes, the installation of high-quality black insect mesh on windows, doors, and screened enclosures creates comfortable, pest-free environments, reducing reliance on chemical pest control and enhancing indoor air quality. Its subtle appearance also means it doesn't detract from the architectural aesthetics of modern structures.

In the agricultural sector, black fly screen mesh plays a critical role in greenhouse cultivation and crop protection. Fine mesh netting is used to create physical barriers that prevent harmful insects like whiteflies, aphids, and indeed black flies from entering greenhouses, thereby safeguarding sensitive crops from pest infestations and diseases. This sustainable approach reduces the need for pesticides, leading to healthier produce and a more environmentally friendly farming practice. For livestock facilities, it provides ventilation while preventing disease-carrying insects from affecting animal health.

Furthermore, industrial applications increasingly leverage specialized black fly screen mesh for filtration and protective purposes. In manufacturing facilities, particularly those involved in food processing or pharmaceuticals, precise insect control is crucial for maintaining hygiene standards and preventing contamination. The mesh is integrated into ventilation systems, air intake filters, and protective enclosures around sensitive machinery to keep out pests and airborne debris. While traditionally used for general insect control, specific variants with enhanced strength and chemical resistance can find niche applications in areas requiring both pest exclusion and a degree of material resilience, such as in certain non-corrosive sections of metallurgy or light industrial air filtration where general debris and insect ingress needs to be managed. Its robust nature makes it suitable for long-term deployment in demanding environments, illustrating its adaptability beyond its common uses.

Tailored Customization Solutions for Specific Needs

Recognizing that a one-size-fits-all approach is rarely effective in B2B applications, leading manufacturers of black fly screen mesh offer comprehensive customization solutions. This flexibility ensures that industrial and commercial clients can acquire products precisely tailored to their unique operational requirements, environmental conditions, and budget constraints. Customization options typically span material composition, mesh count, roll dimensions (width and length), and specialized treatments. For instance, a client in a coastal region might require a mesh with enhanced salt spray resistance, while a food processing plant might prioritize anti-microbial properties and specific fire ratings.

CR Screen, for example, excels in providing bespoke solutions for their Gray Insect Screen and other mesh products. This includes varying the standard mesh counts from a common 18x16 to a finer 20x20 or even 24x24 for specific insect challenges. Wire diameter can also be adjusted to balance airflow with durability. Furthermore, rolls can be supplied in custom widths and lengths to minimize waste and streamline installation for large-scale projects, such as extensive greenhouse coverings or expansive industrial vents. Beyond physical attributes, chemical treatments can be applied to enhance properties like static dissipation, improved dust resistance, or even increased resistance to harsh cleaning agents. Collaborating with a manufacturer capable of such extensive customization ensures that the end product not only meets functional requirements but also integrates seamlessly into existing infrastructure, optimizing performance and delivering long-term value, as evidenced by successful applications in demanding environments such as specialized ventilation systems for chemical storage or controlled atmosphere facilities where precise airflow and insect exclusion are critical.

Quality Assurance, Certifications, and Industry Authority

For B2B purchasers, the reliability and performance of black fly screen mesh are directly linked to the manufacturer's commitment to quality assurance and adherence to international standards. An authoritative supplier will not only meet but often exceed baseline certifications, providing robust evidence of product integrity and consistency. Key certifications like ISO 9001 (Quality Management System) signify a structured approach to manufacturing processes, ensuring that every batch of black fly screen mesh adheres to predetermined quality criteria. This includes rigorous testing protocols for material composition, mesh count accuracy, tensile strength, tear resistance, and UV stability.

Beyond ISO standards, reputable manufacturers will often cite compliance with industry-specific testing methodologies from organizations such as ASTM International (formerly American Society for Testing and Materials) and ANSI (American National Standards Institute). These standards ensure that meshes perform as expected under specific conditions, from fire retardancy (e.g., ASTM E84) to long-term weatherability. For instance, accelerated weathering tests, such as those conducted using fluorescent UV condensation apparatus (per ASTM G154), are critical for predicting the real-world service life of mesh under prolonged sun exposure, directly impacting product longevity and return on investment. Furthermore, a manufacturer's service history, demonstrated through years of operation and a portfolio of successful partnerships with major distributors or direct industrial clients, also reflects their authority and trustworthiness. This long-standing presence in the market, coupled with transparent test data and product specifications, provides the necessary assurance for high-volume or mission-critical applications where failure is not an option.

Frequently Asked Questions (FAQ)

- Q1: What makes black fly screen mesh different from standard insect screens?

- A1: Black fly screen mesh is specifically designed with a finer mesh count (e.g., 20x20 or higher) to block smaller insects like gnats, no-see-ums, and black flies, which can pass through standard 18x16 mesh. The black color also reduces glare and improves outward visibility.

- Q2: What is the typical service life of black fly screen mesh?

- A2: High-quality black fly screen mesh made from PVC-coated fiberglass or durable polyester typically has a service life of 10-15 years, or even longer, depending on environmental exposure and maintenance. This is due to its excellent UV resistance and robust construction.

- Q3: Can black insect mesh be used in humid or coastal environments?

- A3: Yes, most modern black insect mesh made from fiberglass with PVC coating offers excellent resistance to moisture and corrosion, making it highly suitable for humid, coastal, or even industrial environments where exposure to moisture is a concern. For extreme conditions, stainless steel mesh offers superior corrosion resistance.

- Q4: Is custom sizing available for large-scale projects?

- A4: Absolutely. Reputable manufacturers like CR Screen provide extensive customization options, including specific mesh counts, varying wire diameters, and custom roll widths and lengths, to perfectly fit the unique requirements of large commercial, industrial, or agricultural projects.

- Q5: What are the typical lead times for bulk orders of black fly screen mesh?

- A5: Delivery cycles for bulk orders vary based on volume, customization requirements, and current production schedules. Typically, standard product orders can be fulfilled within 2-4 weeks, while highly customized or very large orders may require 6-8 weeks. It is always recommended to consult directly with the manufacturer for precise lead times and shipping logistics tailored to your order.

- Q6: What kind of warranty or after-sales support is provided?

- A6: Most leading manufacturers offer a comprehensive product warranty against manufacturing defects, typically ranging from 5 to 10 years, reflecting confidence in their product's durability. After-sales support often includes technical assistance, installation guidance, and troubleshooting to ensure client satisfaction and optimal product performance throughout its lifecycle.

Conclusion: Securing Your Operations with Advanced Mesh Technology

The strategic integration of high-quality black fly screen mesh is no longer merely a convenience but a critical operational necessity for a broad array of B2B applications. From enhancing the comfort and hygiene of commercial spaces to safeguarding agricultural yields and maintaining sterile industrial environments, the technical advantages of this advanced screening solution are undeniable. Its superior optical properties, exceptional durability against environmental factors like UV radiation and moisture, and its precise ability to exclude even the smallest insects like black flies and gnats, make it an unparalleled choice for long-term protection.

By understanding the intricate manufacturing processes, adhering to rigorous quality standards, and leveraging sophisticated customization options, businesses can make informed procurement decisions that yield significant returns in terms of efficiency, reduced maintenance, and improved overall environmental control. Partnering with an authoritative manufacturer like CR Screen, known for its commitment to quality, technical expertise, and customer-centric solutions, ensures access to products that not only meet but exceed industry expectations. Embracing this advanced mesh technology is a proactive step towards creating more resilient, pest-free, and sustainable operational environments, ultimately contributing to better public health outcomes and operational excellence across diverse industries.

References

- ISO 9001: Quality management systems — Requirements. International Organization for Standardization.

- ASTM International Standards (various, e.g., D5034, D1424, E84, G154) related to textile testing, fire testing, and non-metallic material weathering.

- ANSI/WCMA A100.1-2018: American National Standard for Safety of Corded Window Covering Products. American National Standards Institute.

- FAO. Guidelines for the management of insect pests in greenhouses. Food and Agriculture Organization of the United Nations.

- National Academies of Sciences, Engineering, and Medicine. The Role of the Engineering and Sciences in the Context of a Changing Climate. The National Academies Press.

- Environmental Protection Agency (EPA). Integrated Pest Management (IPM) Principles. United States Environmental Protection Agency.

This is the first article

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025