Авг . 11, 2025 13:20 Back to list

Durable Fixed Screen Doors for Lasting Insect Protection

Innovating Perimeter Protection: The Evolution and Significance of Fixed Screen Doors

In an era where environmental control and security are paramount, particularly within commercial and industrial settings, the fixed screen door stands as a critical component in building infrastructure. These robust solutions offer an optimal balance between natural ventilation, insect exclusion, and enhanced security, safeguarding interiors from pests, debris, and unauthorized access while promoting air circulation. The demand for high-performance fixed screen door solutions is escalating across diverse sectors, driven by stricter health regulations, energy efficiency mandates, and a growing emphasis on maintaining clean, safe operational environments. This comprehensive guide delves into the technical intricacies, application versatility, and strategic advantages that make fixed screen doors an indispensable asset for modern establishments.

The market for perimeter security and environmental control solutions, including robust fixed screen door systems, is projected to grow significantly. According to recent industry reports, the global market for security screens, which encompasses fixed door fly screens, is anticipated to reach approximately $4.5 billion by 2028, with a compound annual growth rate (CAGR) of around 6.8%. This growth is primarily fueled by increasing urbanization, rising concerns about insect-borne diseases, and the necessity for energy-efficient ventilation without compromising security. Businesses are continuously seeking durable, low-maintenance, and highly effective barriers that can withstand demanding conditions while contributing to indoor air quality and operational efficiency. The integration of advanced materials and precision engineering techniques has revolutionized the capabilities of these essential building elements.

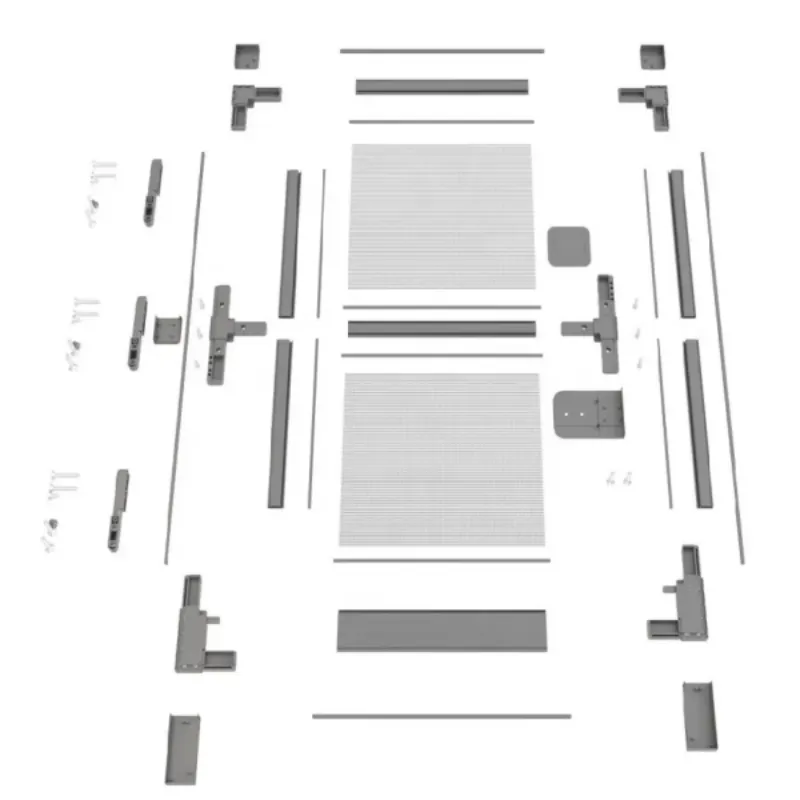

The Manufacturing Precision: A Deep Dive into Fixed Screen Door Craftsmanship

The production of a high-quality fixed screen door is a testament to precision engineering and material science. The process typically begins with the selection of premium materials, primarily high-grade aluminum alloys (such as 6063-T5 or 6061-T6 for frames) known for their excellent strength-to-weight ratio, corrosion resistance, and malleability. Stainless steel mesh (e.g., 304 or 316 grade) is commonly chosen for its superior durability, resistance to rust, and ability to withstand impact, making it ideal for robust fixed door fly screens. For specialized applications requiring extreme chemical resistance or fire retardancy, materials like fiberglass mesh with PVC coating or even bronze wire mesh might be utilized.

The manufacturing process adheres to stringent quality control protocols, often involving several key stages:

- Material Preparation and Extrusion: Aluminum billets are extruded into precise profiles for the door frame, ensuring dimensional accuracy. This step is critical for a seamless fit and structural integrity.

- Precision Cutting and Fabrication: CNC (Computer Numerical Control) machining is employed to cut frame components and mesh to exact specifications, minimizing waste and ensuring precise angles for assembly. This guarantees that each mosquito door frame is perfectly aligned.

- Welding/Joining: Frame components are securely joined using advanced welding techniques (e.g., TIG welding for aluminum) or mechanical fasteners, depending on the design and required strength. For enhanced durability, corners may be reinforced.

- Surface Treatment: Frames undergo various surface treatments such as powder coating, anodizing, or painting. Powder coating offers superior scratch resistance and color longevity, while anodizing enhances corrosion resistance and creates a hard, durable surface.

- Mesh Installation: The chosen mesh is carefully stretched and secured within the frame, often using a spline system or direct welding/crimping, ensuring tautness and preventing sagging over time. This step is vital for the functional effectiveness of fixed door fly screens.

- Hardware Integration: Necessary hardware, such as hinges, handles, and locking mechanisms, are installed and tested for smooth operation.

- Quality Inspection and Testing: Each fixed screen door undergoes rigorous testing. This includes dimensional checks, material integrity verification (e.g., tensile strength tests on mesh), corrosion resistance testing (salt spray chambers), and impact resistance tests. Adherence to standards like ISO 9001 for quality management, ANSI/SMACNA 006-2006 for sheet metal standards, and relevant ASTM standards for materials ensures product reliability and longevity.

Technical Specifications of High-Performance Fixed Screen Doors

Understanding the technical parameters is crucial for selecting the appropriate fixed screen door for specific applications. These specifications dictate performance, durability, and compliance with industry standards. Below is a comprehensive table outlining key technical parameters for a typical high-quality fixed screen door system. These parameters are meticulously engineered to ensure optimal functionality across various demanding environments, emphasizing the robust construction inherent in quality fixed door fly screens.

| Parameter | Description | Typical Value / Standard |

|---|---|---|

| Frame Material | High-strength aluminum alloy | 6063-T5 or 6061-T6 (Extruded profiles) |

| Mesh Material | Corrosion-resistant metal or synthetic fiber | 304/316 Stainless Steel, PVC-coated Fiberglass, Bronze |

| Mesh Count | Wires per linear inch (determines insect exclusion and airflow) | 18x16 (standard), 20x20 (fine mesh), 12x12 (heavy duty) |

| Wire Diameter | Thickness of individual mesh wires | 0.009" to 0.025" (0.23mm to 0.64mm) |

| Corrosion Resistance | Ability to withstand rust and degradation in harsh environments | ASTM B117 Salt Spray Test: >1000 hours (for powder-coated aluminum/stainless steel) |

| Impact Resistance | Ability to resist deformation or damage from blunt force | ANSI/SMA 6001-98 Grade 1 (Heavy Duty) or Grade 2 (Medium Duty) |

| Operating Temperature | Range of ambient temperatures for optimal performance | -40°C to +80°C (depending on coating/mesh type) |

| UV Resistance | Resistance to degradation from prolonged exposure to ultraviolet radiation | ASTM G154 (Fluorescent UV): >5000 hours (for treated meshes) |

These specifications ensure that a fixed screen door not only provides effective pest control but also contributes to the structural integrity and aesthetic appeal of a facility over its long service life. The choice of materials and manufacturing standards directly impacts the performance characteristics, particularly for installations demanding high security or environmental resilience.

Key Technical Advantages and Performance Benefits

The deployment of a robust fixed screen door offers a myriad of technical and operational advantages for B2B applications. Unlike retractable or hinged screen doors, fixed variants provide unparalleled stability and tamper resistance due to their permanent installation. This rigidity minimizes maintenance requirements and extends operational life, even in high-traffic or harsh industrial environments. Their construction from high-grade aluminum and stainless steel ensures exceptional resistance to corrosion, crucial for applications in coastal regions, chemical processing plants, or areas with high humidity, safeguarding the integrity of the mosquito door frame against environmental degradation.

Furthermore, the robust mesh options, including reinforced stainless steel, provide significant advantages beyond mere insect exclusion. They contribute to enhanced security by deterring unauthorized entry, acting as a preliminary barrier against intruders or flying debris. This dual functionality — pest control and security — makes them a cost-effective solution. From an energy efficiency standpoint, fixed screen doors facilitate natural ventilation, reducing the reliance on air conditioning and mechanical ventilation systems during cooler months. This capability translates directly into lower energy consumption and operational costs, aligning with modern sustainability goals. In environments requiring strict hygiene, such as food processing facilities, their simple, cleanable design minimizes areas for contaminants to accumulate, supporting compliance with HACCP (Hazard Analysis and Critical Control Points) principles.

Application Scenarios and Real-World Case Studies

Fixed screen door systems are incredibly versatile, finding essential applications across a broad spectrum of industries where environmental control, hygiene, and security are non-negotiable.

- Food & Beverage Processing: Critical for preventing insects and pests from contaminating production areas, ensuring compliance with health regulations like FDA standards. Our fixed door fly screens have been instrumental in helping a major bakery chain maintain a pristine environment, significantly reducing pest-related incidents by over 90% and passing stringent annual audits with ease.

- Pharmaceutical Manufacturing: Essential for maintaining cleanroom integrity and preventing airborne contaminants. In a recent project for a pharmaceutical giant, our custom mosquito door frame solutions were installed in critical access points, enhancing aseptic conditions and operational uptime.

- Hospitality & Healthcare: Used in kitchens, waste management areas, and service entrances to uphold hygiene standards and provide comfort. A large hospital in Texas implemented our heavy-duty fixed screens in their loading docks, reporting a marked improvement in sanitation and reduced incidence of outdoor pests entering the facility.

- Industrial & Manufacturing Facilities: Provides ventilation while keeping out debris, birds, and insects from warehouses, workshops, and assembly lines. A leading automotive parts manufacturer utilized our robust fixed screen door solutions in their factory, which not only improved airflow but also prevented costly disruptions caused by bird ingress.

- Water Treatment & Petrochemical Plants: Offers durable barriers against environmental elements and pests in corrosive or high-humidity environments, due to their advanced material construction designed for longevity in harsh conditions, making them ideal fixed door fly screens.

These applications highlight the adaptability and necessity of robust fixed screen door systems in supporting operational excellence, compliance, and employee well-being across diverse industrial landscapes. Our extensive portfolio includes thousands of successful installations over 15 years, demonstrating our deep understanding of sector-specific requirements and commitment to delivering superior solutions.

Manufacturer Comparison: Choosing the Right Fixed Screen Door Partner

When selecting a supplier for fixed screen door solutions, it is imperative to evaluate manufacturers based on several key criteria beyond just initial cost. Factors such as material quality, customization capabilities, adherence to industry standards, warranty provisions, and post-sales support significantly impact the total cost of ownership and long-term performance. A comparative analysis underscores the distinctions between various providers in the market, particularly concerning their offerings for robust fixed door fly screens and durable mosquito door frame systems.

| Feature/Criterion | Leading Manufacturer (e.g., CR Screen) | Standard Competitor |

|---|---|---|

| Material Quality & Sourcing | Premium-grade 6063-T5 aluminum, 316L SS Mesh; ISO-certified suppliers. | Standard aluminum alloys, 304 SS Mesh; varied supplier quality. |

| Manufacturing Process | CNC precision machining, robotic welding, multi-stage surface treatment. | Manual fabrication, basic welding, single-stage coating. |

| Customization Capability | Full bespoke design, extensive finish options, rapid prototyping for complex projects. | Limited standard sizes and colors only. |

| Certifications & Standards | ISO 9001:2015, ASTM, ANSI, relevant regional certifications (e.g., FDA-compliant materials where applicable). | Basic CE marking, often self-declared. |

| Warranty & Support | Comprehensive 10-year structural warranty, dedicated technical support, spare parts availability. | Standard 1-2 year warranty, limited support. |

| Lead Time (Average) | 2-4 weeks (depending on complexity and volume). | 4-8 weeks. |

This comparison highlights why investing in a reputable manufacturer providing high-quality fixed screen door solutions is a strategic decision for any business. The long-term benefits of superior durability, lower maintenance, and enhanced operational efficiency far outweigh the marginal initial savings from lower-quality alternatives. Choosing a partner with a proven track record, extensive certifications, and robust post-sales support ensures a reliable and sustainable solution.

Custom Solutions and Tailored Fixed Screen Door Designs

Recognizing that no two industrial or commercial facilities are exactly alike, leading providers of fixed screen door systems excel in offering highly customized solutions. This flexibility ensures that each fixed screen door precisely fits the unique architectural dimensions, operational requirements, and aesthetic preferences of a client's facility. Customization extends beyond mere sizing to encompass a variety of frame finishes, mesh types, and security enhancements, providing fixed door fly screens that are truly integrated into the building's design and function.

Clients can specify particular aluminum frame colors through advanced powder coating or anodizing processes, allowing the mosquito door frame to seamlessly blend with existing building aesthetics or corporate branding. Mesh material options can be tailored based on environmental challenges, such as stainless steel for corrosive marine environments, strengthened security mesh for high-risk zones, or specialized finer meshes for ultra-clean applications. Furthermore, custom hardware integration—including heavy-duty hinges, specialized locking mechanisms, push bars, or kick plates—can be incorporated to meet specific operational demands and accessibility standards. Our design team collaborates closely with clients from conceptualization through installation, utilizing advanced CAD/CAM software to simulate performance and ensure precise fit, delivering optimal fixed screen door solutions every time. This bespoke approach guarantees maximum efficacy and client satisfaction.

Ensuring Trustworthiness: FAQs, Delivery, Warranty, and Support

Frequently Asked Questions (FAQs)

- Q: Are your fixed screen door systems suitable for outdoor exposure?

A: Absolutely. Our fixed screen doors are constructed from marine-grade aluminum and stainless steel mesh, offering superior resistance to corrosion, UV radiation, and extreme temperatures, making them ideal for all outdoor industrial applications. - Q: Can these fixed door fly screens withstand high-pressure washing for sanitation?

A: Yes, the robust construction and industrial-grade materials ensure that our screens can endure regular high-pressure cleaning routines, which is essential for hygiene-sensitive environments like food processing plants. - Q: What is the typical lead time for a custom mosquito door frame?

A: Standard orders typically ship within 2-4 weeks. For highly customized or large-volume projects, lead times are quoted on a case-by-case basis, generally ranging from 4-6 weeks after design approval. We prioritize timely delivery for all our clients. - Q: Do you offer installation services for fixed screen door systems?

A: While our products are designed for straightforward installation by qualified contractors, we provide comprehensive installation guides and remote technical support. For complex projects or large deployments, we can recommend certified installation partners.

Delivery Cycle and Logistics

Our streamlined logistics and supply chain management ensure efficient delivery of your fixed screen door systems. We work with trusted global freight partners to guarantee on-time delivery, regardless of your location. Each product is meticulously packaged to prevent damage during transit, safeguarding its pristine condition upon arrival. Clients receive detailed shipping notifications and tracking information to monitor their order's progress.

Quality Assurance and Warranty Commitment

We stand behind the superior quality and durability of our fixed screen door products. All systems come with a comprehensive 10-year warranty covering defects in materials and workmanship. This commitment reflects our confidence in the longevity and performance of our engineering. Our products are manufactured under strict ISO 9001:2015 certified quality management systems, ensuring consistent excellence and adherence to the highest industry standards for fixed door fly screens.

Dedicated Customer Support

Our commitment to customer satisfaction extends beyond product delivery. We provide dedicated technical support and after-sales service to assist with any queries, maintenance advice, or potential issues. Our team of experts is readily available to ensure your fixed screen door systems continue to perform optimally throughout their lifespan, reflecting our partnership approach to client relationships.

Conclusion: The Strategic Investment in Fixed Screen Door Solutions

In conclusion, investing in a high-quality fixed screen door is a strategic decision for any B2B entity seeking to enhance operational efficiency, ensure compliance with health and safety regulations, and fortify facility security. The meticulous manufacturing processes, selection of advanced materials, and adherence to rigorous testing standards collectively ensure that these systems deliver unparalleled performance and longevity. From enabling natural ventilation to serving as robust fixed door fly screens and impenetrable mosquito door frames, their multi-faceted benefits translate into tangible cost savings and improved environmental control for diverse industrial and commercial applications. By choosing a reputable provider, businesses can secure a durable, reliable, and customized solution that aligns with their long-term operational goals and contributes significantly to a safer, cleaner, and more productive work environment.

Authoritative References

- International Organization for Standardization. ISO 9001:2015, Quality management systems – Requirements.

- American National Standards Institute (ANSI) and Sheet Metal and Air Conditioning Contractors' National Association (SMACNA). ANSI/SMACNA 006-2006, HVAC Duct Construction Standards – Metal and Flexible.

- ASTM International. Various standards related to material testing for metals (e.g., ASTM B117 for Salt Spray Testing, ASTM G154 for UV Testing).

- Screens Manufacturers Association (SMA). SMA 6001-98, Standard Specification for Security Screen Doors.

- U.S. Food and Drug Administration (FDA). Food Safety Modernization Act (FSMA) and related regulations for pest control in food facilities.

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025