Авг . 10, 2025 07:00 Back to list

Magnetic Window Net: Easy Install & Bug-Free Fresh Air

Industry Trends and Market Dynamics for Advanced Magnetic Window Solutions

The global demand for innovative and efficient fenestration solutions has been steadily escalating, driven by evolving consumer preferences, stringent building codes, and a heightened focus on energy efficiency and indoor air quality. Within this dynamic landscape, the advent and rapid adoption of the magnetic window net represent a significant paradigm shift. This ingenious product, often interchangeably referred to as magnetic window mesh or magnetic screen window, addresses multifaceted challenges posed by traditional screening methods, offering unparalleled ease of use, superior aesthetics, and enhanced functionality. The market trajectory indicates a robust compound annual growth rate (CAGR), fueled by urbanization, increasing disposable incomes in emerging economies, and a growing awareness regarding health and well-being. Consumers and businesses alike are increasingly seeking solutions that seamlessly integrate with modern architectural designs while providing effective protection against insects, allergens, and airborne particulates, without compromising ventilation or natural light. The versatility of these magnetic solutions extends their application beyond conventional residential settings into commercial, healthcare, and hospitality sectors, where maintaining sterile environments and ensuring occupant comfort are paramount.

Technological advancements play a pivotal role in this growth. Innovations in magnetic strip technology, mesh material science, and frame design have collectively enhanced the durability, efficiency, and aesthetic appeal of the magnetic window net. For instance, the transition from conventional fiberglass mesh to more robust, UV-resistant, and flame-retardant materials like PVC-coated polyester or even advanced stainless steel mesh for specialized applications, significantly extends product lifespan and performance. Furthermore, the emphasis on DIY-friendly installation and maintenance has broadened their market appeal, allowing for quick deployment and removal without requiring specialized tools or professional assistance. The sustainability aspect also contributes to their market pull; by facilitating natural ventilation, these screens reduce reliance on air conditioning, thereby contributing to lower energy consumption and a smaller carbon footprint. The integration of smart home technologies, though nascent in this specific product category, presents a future growth vector, potentially allowing for automated screen deployment or environmental monitoring. As urban populations continue to expand and environmental concerns become more pronounced, the market for intelligent, adaptable, and energy-efficient window screening solutions like the magnetic screen window is poised for sustained expansion. Industry reports project the global window screen market to reach values exceeding $XX billion by 2030, with magnetic variants capturing an increasingly significant share due to their inherent advantages in adaptability and user convenience. This section sets the stage for a deeper dive into the technical intricacies and operational benefits that define the leadership position of high-quality magnetic window mesh products in today's demanding market.

Unveiling the Advanced Manufacturing Process of Magnetic Screen Windows

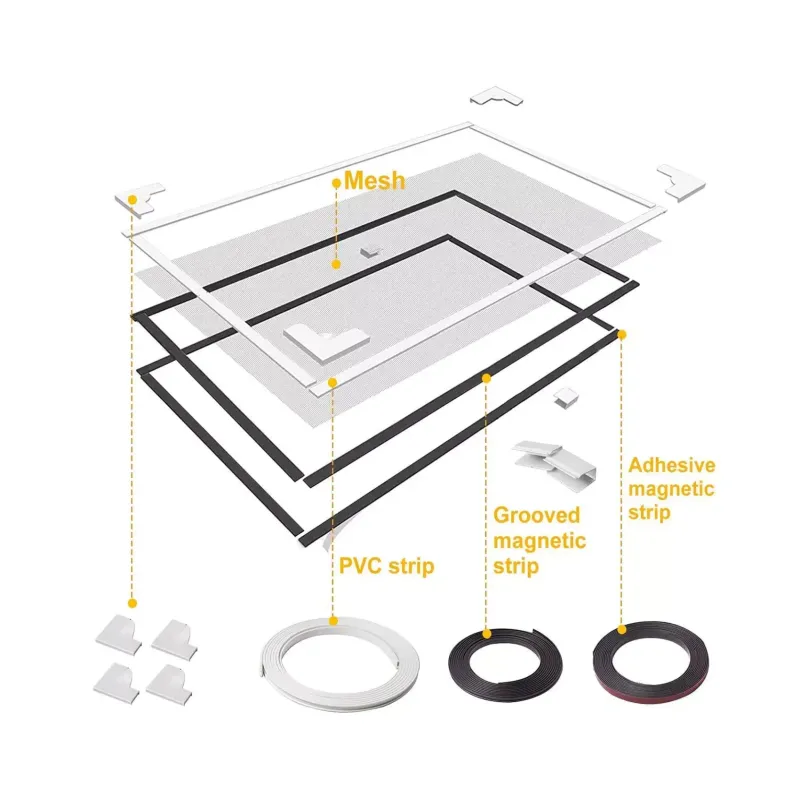

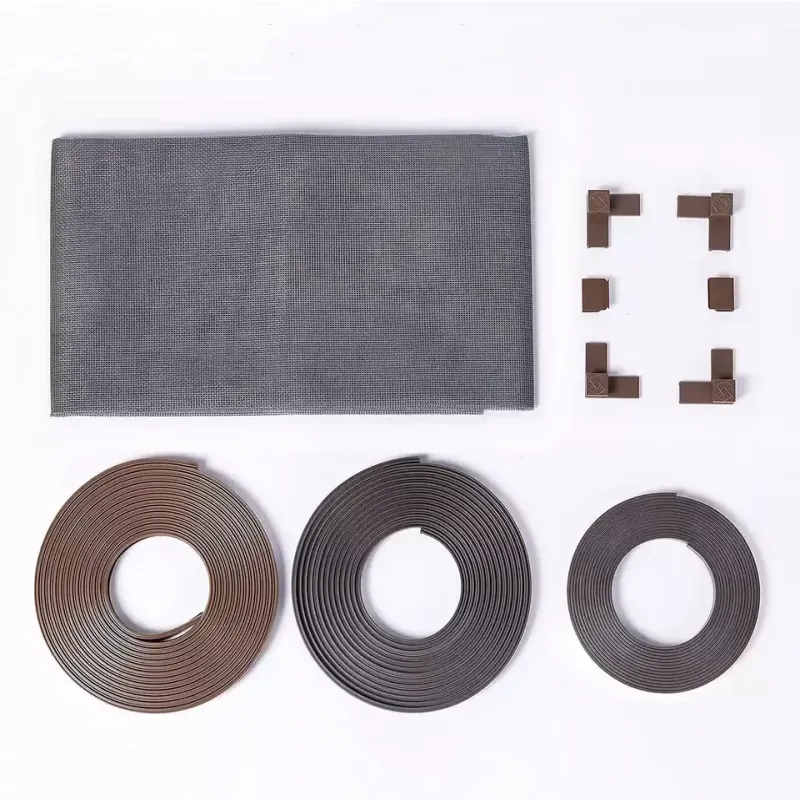

The fabrication of a high-quality magnetic window net involves a meticulous multi-stage manufacturing process, emphasizing precision engineering, material science, and stringent quality control at every juncture. Unlike heavy industrial components requiring casting or forging, the production of a magnetic screen window is centered around advanced cutting, bonding, and assembly techniques. The process typically commences with the selection of premium-grade materials, crucial for ensuring the product's longevity, aesthetic appeal, and functional integrity. The primary components include the mesh material, the flexible magnetic strips, and the peripheral frame or sealing materials. Common mesh choices range from durable fiberglass, renowned for its excellent tear resistance and UV stability, to polyester for enhanced resilience against pet damage, and even specialized stainless steel or aluminum mesh for applications demanding superior strength or fire resistance. These materials are chosen based on their specified denier (for synthetic fibers), weave pattern (e.g., 18x16 or 20x20 mesh count), and coating properties (e.g., PVC coating for weather resistance and easy cleaning). Flexible magnetic strips, typically made from ferrite powder mixed with polymer binders, are selected for their consistent magnetic flux density and durability, ensuring a robust and secure seal against the window frame.

The manufacturing workflow typically follows these key steps: First, Material Preparation and Cutting. Large rolls of mesh material are precisely cut to the required dimensions using automated CNC cutting machines, minimizing waste and ensuring dimensional accuracy. Simultaneously, magnetic strips are also cut to match the perimeter of the screen. This automated precision is critical for seamless fitment. Second, Hemming and Edge Sealing. The cut mesh edges are expertly hemmed or thermally sealed to prevent fraying and enhance structural integrity. This step is vital for the longevity of the magnetic window mesh, preventing unraveling even after years of use and cleaning. Third, Magnetic Strip Integration. The flexible magnetic strips are then securely attached to the perimeter of the mesh. This can involve high-frequency welding, ultrasonic bonding, or specialized adhesive techniques, ensuring a permanent and strong bond that withstands repeated opening and closing cycles. The polarity of the magnets is meticulously checked to ensure proper attraction when installed. Fourth, Frame Assembly (Optional). For models incorporating a rigid or semi-rigid frame, typically made from high-grade PVC, aluminum alloy, or composite materials, these frame components are cut, mitered, and assembled around the magnetic mesh. This frame provides additional structural stability and a refined aesthetic. Fifth, Quality Control and Testing. Each manufactured magnetic screen window undergoes rigorous quality control checks. This includes visual inspections for material flaws, dimensional verification using precision gauges, magnetic pull-force testing to ensure adequate sealing strength (measured in pounds per linear inch or Newton per meter), and functional tests to confirm ease of installation and removal. Adherence to international standards such as ISO 9001 for quality management systems is paramount, ensuring consistency and reliability across batches. Furthermore, some products may undergo specific tests for UV degradation resistance, wind load resistance, or flame retardancy, particularly for applications in demanding environments. This comprehensive process, from raw material selection to final inspection, ensures that the end product, the magnetic window net, delivers on its promise of durability, effectiveness, and user satisfaction, embodying the principles of modern precision manufacturing. The typical lifespan of a well-manufactured unit can exceed 10-15 years under normal residential use, with commercial applications varying based on usage intensity.

Key Technical Parameters and Specifications of High-Performance Magnetic Window Nets

Understanding the critical technical parameters and specifications is essential for B2B decision-makers when procuring magnetic window net solutions, ensuring the chosen product aligns perfectly with project requirements, performance expectations, and regulatory compliance. These parameters define the efficacy, durability, and suitability of the magnetic screen window for various applications. Beyond simple dimensions, a comprehensive evaluation includes scrutinizing the materials used, the characteristics of the mesh, the strength of the magnetic seal, and the overall structural integrity. For instance, the mesh material significantly impacts visibility, airflow, and resistance to environmental factors. Fiberglass mesh, often PVC-coated, offers excellent balance between affordability, durability, and view-through clarity, typically with a standard mesh count of 18x16 or 20x20 threads per inch – higher counts offer better insect protection but slightly reduce airflow and light transmission. Polyester mesh, on the other hand, is noted for its superior tear and puncture resistance, making it ideal for homes with pets or in areas prone to heavier usage. Specialized materials like stainless steel mesh provide unparalleled strength and resistance to corrosion, making them suitable for industrial or high-security applications where robust physical barriers are required. The tensile strength of the mesh, measured in PSI or N/mm², indicates its resistance to stretching or breaking under tension, a critical factor for long-term performance.

The magnetic component is another pivotal aspect of the magnetic window mesh. The type of magnet (e.g., flexible ferrite, rubber magnet) and its magnetic pull force are crucial for a tight, bug-proof seal. This force is often specified in grams per square centimeter or ounces per linear foot, directly correlating to the screen's ability to remain securely attached even under wind pressure. High-quality magnetic strips maintain their magnetic properties over extended periods and in varying temperatures, preventing degradation and ensuring consistent sealing. The frame material, whether PVC, aluminum alloy, or a composite, contributes to the overall rigidity and aesthetic. PVC frames offer good thermal insulation and cost-effectiveness, while aluminum provides greater structural strength and a sleek, modern appearance. Durability parameters such as UV resistance (tested by accelerated weathering, often measured in hours before degradation begins), flame retardancy (meeting standards like UL 94 V-0 or similar building codes), and wind load resistance (often specified in miles per hour or Pascal, indicating the maximum wind speed the screen can withstand without dislodging) are critical for product longevity and safety. Furthermore, dimensional stability – the screen's ability to resist shrinking or expanding due to temperature or humidity changes – ensures a consistent fit over time. Reputable manufacturers provide detailed technical data sheets (TDS) and material safety data sheets (MSDS) for their products, confirming adherence to industry benchmarks such as ASTM (American Society for Testing and Materials) for material properties and performance, or CE certification for European market entry. Below is a representative table of common technical parameters for high-performance magnetic screen window products, offering a benchmark for evaluation.

| Parameter | Typical Specification Range | Description & Significance |

|---|---|---|

| Mesh Material | Fiberglass (PVC Coated), Polyester, Stainless Steel, Aluminum | Determines durability, visibility, airflow, and specific resistances (e.g., pet-proof, fire-resistant). |

| Mesh Count (Threads/Inch) | 18x16 to 20x20 (standard); 30x30+ (no-see-um mesh) | Higher count offers better insect protection; affects light and airflow transmission. |

| Magnetic Strip Material | Flexible Ferrite (Rubber Magnet), PVC-encased | Ensures consistent magnetic properties and flexibility for tight seal. |

| Magnetic Pull Force | 30-60 grams/cm² (or 2-4 oz/linear foot) | Measure of holding power; critical for maintaining seal against wind and wear. |

| UV Resistance | >1000 hours (QUV A/B 340 test) | Resistance to degradation from sunlight exposure, preventing brittleness and color fading. |

| Tensile Strength | >250 N/5cm (mesh), >500 N/5cm (magnetic strip adhesion) | Measures resistance to stretching/breaking; critical for durability against impacts. |

| Wind Load Resistance | Up to 40-50 mph (approx. 65-80 km/h or 192-240 Pa) | Maximum wind speed the screen can withstand without detaching. |

| Temperature Range | -30°C to +80°C (-22°F to +176°F) | Operating range where material properties and magnetic strength remain stable. |

| Fire Retardancy (Optional) | UL 94 V-0 or similar building code compliance | Ability to self-extinguish or resist ignition, important for commercial/public buildings. |

Diverse Application Scenarios and Sectoral Integration of Magnetic Screen Windows

The adaptability and superior performance characteristics of the magnetic window net have facilitated its integration across a broad spectrum of application scenarios, transcending conventional residential use to address complex challenges in commercial, industrial, and specialized environments. Its inherent benefits, such as ease of installation, superior sealing, and aesthetic flexibility, make it a preferred solution for a diverse clientele. In the residential sector, the primary application remains insect exclusion, particularly in regions prone to mosquitoes and other pests. Homeowners value the ability to enjoy fresh air circulation without compromising indoor comfort or security. Beyond basic pest control, the magnetic screen window also offers protection against pollen and fine dust, particularly with finer mesh counts, contributing to improved indoor air quality for allergy sufferers. The ease of removal for cleaning or seasonal storage further enhances its appeal, distinguishing it from permanent or cumbersome traditional screens. Apartment complexes, condominiums, and housing developments are increasingly specifying these solutions during construction or renovation due to their cost-effectiveness, durability, and tenant satisfaction.

Moving into the commercial domain, the utility of the magnetic window mesh expands significantly. In the hospitality industry, hotels and resorts leverage these screens to provide guests with a comfortable, pest-free environment, enhancing their stay experience. Restaurants, cafes, and food service establishments adhere to stringent health regulations that necessitate effective insect barriers, especially in kitchen and dining areas. The ability to quickly remove and clean these screens is a major advantage for maintaining hygiene standards. Educational institutions, including schools and universities, employ them to ensure comfortable learning environments free from distractions caused by insects, particularly during warmer months when natural ventilation is preferred. Healthcare facilities, clinics, and laboratories utilize advanced versions of the magnetic screen window to maintain sterile conditions, preventing ingress of pests that could compromise patient care or research integrity. For these sensitive environments, screens made from antimicrobial-treated mesh or fine stainless steel mesh are often specified to meet strict sanitation protocols. In light industrial settings, such as small manufacturing plants, workshops, or food processing units, these screens provide an effective barrier against airborne contaminants and pests while allowing crucial ventilation. Their robust construction and ease of maintenance are critical in such demanding operational contexts. The adaptability to various window types—casement, sliding, double-hung, and even unique architectural designs—underscores their versatility. This wide-ranging applicability, combined with their operational benefits, positions the magnetic window net as a critical component in modern building design and facility management strategies across various sectors seeking efficient, flexible, and hygienic ventilation solutions.

In-Depth Analysis of Technical Advantages: Why Choose Magnetic Window Nets?

The compelling technical advantages offered by a high-quality magnetic window net firmly establish it as a superior alternative to traditional screening methods, providing a blend of functionality, durability, and user convenience that aligns with modern B2B procurement objectives. At the core of its technical superiority is the innovative magnetic sealing mechanism. Unlike conventional screens that often rely on cumbersome latches, clips, or rigid frames that require precise installation and are prone to gaps, the continuous magnetic strip provides a complete, uninterrupted seal around the entire perimeter of the window opening. This creates an impermeable barrier against insects, dust, and allergens, significantly enhancing indoor hygiene and comfort. The magnetic closure also ensures effortless installation and removal. Homeowners or facility managers can simply attach or detach the screen in seconds without needing tools, drilling, or permanent alterations to the window frame. This ease of operation is a critical factor for maintenance, cleaning, and seasonal storage, vastly simplifying upkeep compared to fixed screen installations.

Furthermore, the design flexibility and material resilience of the magnetic screen window contribute significantly to its technical prowess. The use of high-grade fiberglass or polyester mesh, often coated with PVC, offers exceptional resistance to UV degradation, ensuring that the screen does not become brittle, fade, or tear prematurely under prolonged sun exposure. This UV stability, often tested to rigorous ASTM standards (e.g., G154), means a longer service life and reduced replacement frequency, translating into lower lifecycle costs for commercial applications. The mesh material also boasts excellent tensile strength and tear resistance, making it robust against accidental impacts or pet damage. Unlike metal screens that can corrode or fiberglass that can crease permanently, modern synthetic meshes exhibit a remarkable ability to retain their shape and integrity. The permeability of the mesh, designed to maximize airflow while filtering out unwanted particles, ensures optimal ventilation without compromising light transmission. This superior ventilation capability contributes to energy efficiency by reducing reliance on air conditioning, particularly during mild weather, aligning with green building initiatives. The minimal profile of the magnetic window mesh also maintains the aesthetic integrity of the building’s façade, providing an almost invisible barrier that doesn't obstruct views or detract from architectural design. Moreover, the inherent corrosion resistance of the materials, especially for marine-grade options or those with specialized coatings, extends the product's applicability to coastal areas or environments with high humidity or chemical exposure. In summary, the technical advantages—from the robust magnetic seal and effortless operability to superior material durability and energy efficiency—make the magnetic window net an intelligent, cost-effective, and high-performance choice for diverse fenestration needs in both residential and commercial sectors.

Comparative Analysis: Selecting the Optimal Magnetic Window Solution Provider

For B2B buyers, the selection of a reliable manufacturer for magnetic window net solutions is a critical decision that impacts not only product quality and performance but also project timelines, cost-efficiency, and long-term operational sustainability. A thorough comparative analysis involves evaluating potential suppliers across several key dimensions that extend beyond mere price points to encompass the holistic value proposition. Firstly, Material Quality and Sourcing Transparency are paramount. Leading manufacturers will explicitly detail the origin and specifications of their mesh (e.g., virgin PVC-coated fiberglass, medical-grade stainless steel) and magnetic components (e.g., high-coercivity flexible ferrite). They should provide technical data sheets and material safety data sheets, adhering to international standards like RoHS or REACH. Inferior materials can lead to premature degradation, reduced magnetic pull force, and compromised insect protection. Secondly, Manufacturing Precision and Quality Control are non-negotiable. Look for manufacturers that employ automated cutting and assembly processes, adhering to ISO 9001 certified quality management systems. Evidence of rigorous in-process and final product testing, including dimensional accuracy, tensile strength, UV resistance, and magnetic pull force, indicates a commitment to consistent, high-grade output. Manufacturers should be able to provide test reports from independent third-party laboratories.

Thirdly, Customization Capabilities and Design Flexibility are vital for B2B projects. While standard sizes are common, many commercial or architectural projects require custom dimensions, specialized mesh types (e.g., pollen screens, pet-resistant screens, security screens), or specific frame colors/materials to match unique design aesthetics or functional requirements. A reputable manufacturer for magnetic window mesh should offer robust design and engineering support to tailor solutions. Fourthly, Certifications and Industry Compliance signal authority and reliability. Certifications like CE (for European markets), relevant ASTM standards, or local building code approvals demonstrate adherence to safety and performance benchmarks. Membership in industry associations also indicates a commitment to best practices. Fifth, After-Sales Support, Warranty, and Delivery Logistics are crucial for long-term partnership. A comprehensive warranty (typically 5-10 years on materials and workmanship) provides assurance. Clear communication regarding lead times, shipping logistics, and responsive customer service for technical queries or post-delivery support are indicators of a trustworthy partner. Finally, R&D and Innovation capacity showcases a manufacturer's commitment to staying ahead of market trends and offering advanced solutions. This could include developing new mesh technologies, enhanced magnetic systems, or smart integration features for the magnetic screen window. A comparative table is provided below to aid in a structured evaluation of potential suppliers, highlighting key differentiating factors.

| Evaluation Criterion | High-Value Manufacturer | Lower-Tier Manufacturer (Risks) |

|---|---|---|

| Material Quality & Sourcing | Virgin materials, traceable origin, UV/fire-resistant coatings, durable magnets. | Recycled/sub-standard materials, unknown origin, rapid degradation/fading. |

| Manufacturing Standards | ISO 9001 certified, automated processes, strict QC, third-party testing reports. | Manual processes, inconsistent quality, no verifiable certifications/tests. |

| Customization & R&D | Offers full customization, strong R&D, diverse mesh/frame options, engineering support. | Limited standard sizes only, no customization, stagnant product line. |

| Certifications & Compliance | CE, RoHS, ASTM, local building code approvals, reputable industry memberships. | No relevant certifications, or questionable/fake documentation. |

| After-Sales & Warranty | Long-term warranty (5-10 years+), responsive support, clear delivery terms. | Short/no warranty, poor communication, lack of support for issues. |

| Pricing Model | Competitive value-based pricing, transparent cost breakdown for bulk orders. | Unrealistically low prices often indicative of poor quality, hidden costs. |

Tailored Customization Solutions for Specific Project Requirements

In the B2B landscape, a one-size-fits-all approach rarely suffices, especially for architectural, commercial, or specialized industrial projects. Recognizing this, leading manufacturers of magnetic window net products offer comprehensive customization solutions designed to meet the unique specifications and aesthetic demands of diverse applications. This capability is a cornerstone for architects, contractors, and facility managers who require precise fits, specific functionalities, or unique visual integration. The most fundamental aspect of customization revolves around dimensions. While standard sizes are widely available, virtually every commercial building or renovation project features unique window opening dimensions. A proficient manufacturer will provide precise measurement guides and offer custom fabrication services to ensure a perfect, seamless fit for every aperture, regardless of its shape or size. This eliminates the need for on-site modifications, which can be costly and compromise product integrity. Beyond basic sizing, the choice of mesh type is another critical area for customization. Projects in areas with extreme insect pressure might require a finer mesh count (e.g., 30x30 "no-see-um" mesh) for enhanced protection against gnats or tiny midges. For households or commercial spaces with pets, a more robust, pet-resistant polyester mesh can be specified to withstand claws and playful interactions without tearing.

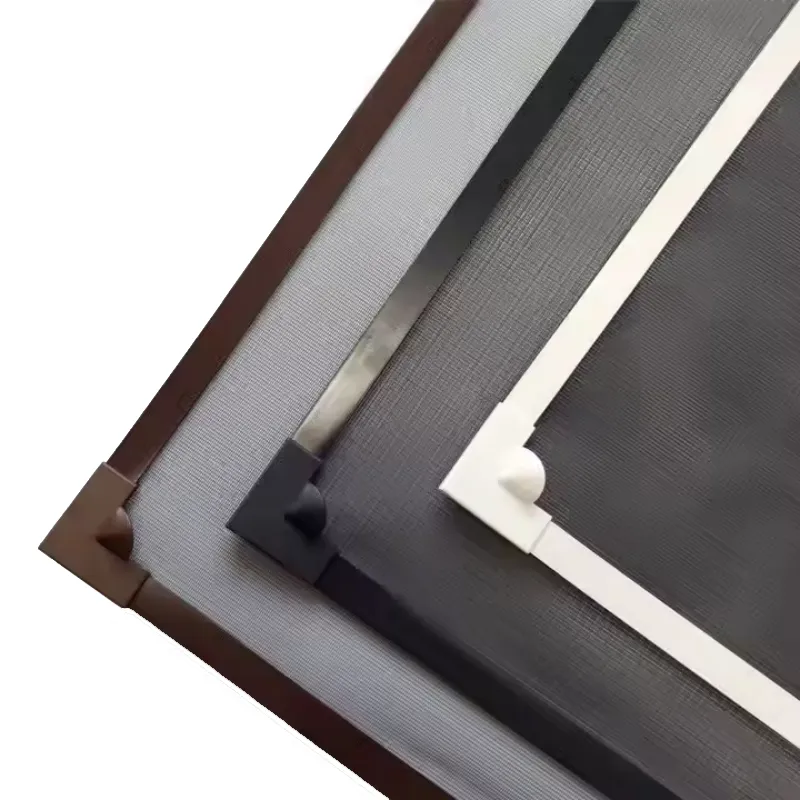

Furthermore, the aesthetic integration of the magnetic screen window is often a crucial factor in high-end residential or commercial architectural designs. Customization extends to frame colors and materials. While white, black, and brown are standard, manufacturers can match custom RAL or Pantone colors to complement existing window frames, building façades, or interior design schemes. Frame materials can also be chosen based on desired durability, thermal performance, or sleekness—from cost-effective PVC to premium extruded aluminum. For specialized applications, the magnetic strip itself can be customized in terms of strength and profile. For instance, in areas with high wind loads, a stronger magnetic pull force might be necessary to ensure the magnetic window mesh remains securely attached. Conversely, for applications where frequent removal by children or elderly individuals is expected, a slightly lighter magnetic strength might be preferred for ease of operation. Beyond these common customizations, advanced manufacturers can integrate additional functionalities. This includes incorporating antimicrobial treatments into the mesh for healthcare environments, fire-retardant properties for compliance with specific building codes, or even specialized coatings for enhanced privacy or glare reduction. The ability to tailor every aspect of the magnetic window net—from its dimensions and material composition to its functional attributes and aesthetic finish—ensures that the final product not only meets but exceeds the stringent and diverse demands of modern B2B projects, delivering optimal performance and seamless integration. This client-centric approach to manufacturing is vital for fostering long-term partnerships and delivering truly value-added solutions.

Illustrative Application Cases and Success Stories

The practical utility and demonstrable success of the magnetic window net are best illustrated through real-world application cases, showcasing its efficacy across various sectors. These examples underscore the product's adaptability, ease of integration, and significant benefits in diverse operational environments.

Case Study 1: Upscale Residential Complex – Enhanced Comfort and Aesthetic Preservation. A luxury apartment complex located in a metropolitan area with significant seasonal insect activity sought a modern screening solution that would not detract from the building's high-end aesthetics. Traditional bulky screen frames were deemed unsuitable. The solution involved custom-fabricated magnetic screen window units for over 300 apartment windows. Each unit was precisely measured and manufactured using fine-mesh fiberglass (20x20 mesh count) with slim, color-matched PVC magnetic frames that blended seamlessly with the existing window profiles. The magnetic attachment system allowed residents to effortlessly install or remove the screens for cleaning or during colder months, appreciating the unobstructed views and superior insect protection. This project resulted in a significant increase in tenant satisfaction ratings related to indoor comfort and air quality, validating the aesthetic and functional superiority of the magnetic window mesh. Client feedback emphasized the ease of use and the product's near-invisibility from both interior and exterior perspectives.

Case Study 2: Boutique Hotel Chain – Hygiene and Guest Experience Optimization. A boutique hotel chain operating in a tropical climate faced persistent challenges with insect ingress into guest rooms and dining areas, negatively impacting guest experience and health scores. Permanent screens were considered too costly to install and maintain across multiple properties. The chain adopted a phased rollout of magnetic window net solutions, custom-sized for various window types, including large patio doors in suites. The key benefits were the robust magnetic seal that prevented even tiny insects from entering, and the ease with which housekeeping staff could remove and clean the screens, maintaining impeccable hygiene standards. The PVC-coated fiberglass mesh proved durable against high humidity and frequent use. Post-implementation, the hotel chain reported a 40% reduction in guest complaints related to insects and an overall improvement in positive guest reviews concerning room comfort and cleanliness. The screens also allowed guests to enjoy natural breezes, contributing to a more pleasant stay and potentially reducing air conditioning costs for the hotel.

Case Study 3: Food Processing Facility – Strict Pest Control and Ventilation Compliance. A medium-sized food processing plant needed to upgrade its insect control measures to comply with stringent food safety regulations (e.g., HACCP standards), requiring absolute exclusion of pests while maintaining adequate ventilation in processing areas. Traditional industrial screens were difficult to clean and often left small gaps. The facility implemented custom-fabricated magnetic screen window units with industrial-grade, tight-weave stainless steel mesh (20x20 mesh count for enhanced durability and pest exclusion). The magnetic attachment allowed for quick removal by sanitation teams during daily wash-downs, ensuring no residues or contaminants were trapped. The stainless steel mesh offered superior corrosion resistance in the damp processing environment and was easy to sanitize. This investment resulted in zero reported pest-related contamination incidents for two consecutive years, significantly improving the plant's audit scores and operational efficiency. The robust design and ease of cleaning for the magnetic window mesh were highlighted as critical factors in achieving compliance and operational excellence.

Ensuring Reliability: Quality Assurance, Warranty, and Customer Support

For any B2B purchase, especially one involving infrastructure or long-term operational impact, the commitment to quality assurance, robust warranty provisions, and comprehensive customer support are as crucial as the product's technical specifications. A reputable manufacturer of magnetic window net solutions understands that trust is built on reliability and responsiveness, extending far beyond the point of sale. Quality assurance (QA) begins at the raw material procurement stage, with strict vendor qualification processes and incoming material inspections to verify adherence to specified standards for mesh, magnets, and frame components. This proactive approach minimizes the risk of defects down the line. Throughout the manufacturing process, statistical process control (SPC) techniques and in-line inspections are employed to monitor critical parameters such as cutting precision, adhesion strength of magnetic strips, and overall dimensional accuracy. Each magnetic screen window undergoes a final quality inspection before packaging, ensuring that every unit meets the stringent performance benchmarks set by the company and relevant industry standards. This includes visual checks for aesthetic flaws, functional tests for magnetic seal integrity, and confirmation of correct sizing. Adherence to international quality management systems such as ISO 9001:2015 is a fundamental indicator of a manufacturer's commitment to consistent quality and continuous improvement. External audits and certifications further validate these internal processes, providing objective proof of quality control efficacy.

A strong warranty policy serves as a testament to the manufacturer's confidence in their product's durability and performance. For high-quality magnetic window mesh, a standard warranty typically covers manufacturing defects for a period of 5 to 10 years, sometimes extending to specific components like the mesh's UV resistance or the magnetic strip's integrity. This comprehensive coverage provides B2B clients with peace of mind, knowing their investment is protected against premature failure due to faults in materials or workmanship. Clear terms and conditions for warranty claims, along with a streamlined process for addressing issues, are vital. Beyond formal warranties, exceptional customer support distinguishes leading suppliers. This encompasses pre-sales technical consultation, where experienced engineers or product specialists assist clients in selecting the appropriate magnetic window net specifications, provide measurement guidelines, and offer installation advice. During the order fulfillment phase, proactive communication regarding production status, estimated delivery times, and shipping logistics ensures transparency and helps clients manage project schedules. Post-sales support includes technical assistance for installation queries, troubleshooting, and guidance on maintenance and cleaning. A dedicated customer service team, accessible via multiple channels (phone, email, online portal), is crucial for timely and effective problem resolution. Furthermore, a manufacturer committed to long-term partnerships often provides training materials, video tutorials, and detailed instruction manuals to empower clients with the knowledge to maximize the product's lifespan and performance. This holistic approach to quality, warranty, and support underpins the reliability and trustworthiness of a chosen supplier, ensuring that the lifecycle value of the magnetic screen window is fully realized for all B2B applications.

Frequently Asked Questions (FAQ)

Here are some frequently asked questions regarding the magnetic window net, providing quick answers to common inquiries from B2B clients and end-users.

Q1: What are the primary advantages of a magnetic window net over traditional fixed or roll-up screens?

The core advantages of a magnetic window net include unparalleled ease of installation and removal (no drilling, tools, or permanent alteration to window frames), a superior, continuous magnetic seal that effectively prevents even tiny insects from entering, and enhanced aesthetics due to its slim profile. Unlike traditional screens, it can be quickly detached for cleaning, seasonal storage, or to enjoy an unobstructed view, offering significant operational flexibility and maintenance benefits for both residential and commercial applications.

Q2: How durable is the magnetic screen window, especially concerning UV exposure and pet damage?

High-quality magnetic screen window products are designed for exceptional durability. They typically utilize PVC-coated fiberglass mesh which is inherently UV-resistant, preventing brittleness and fading even after prolonged exposure to sunlight. For homes or facilities with pets, specialized polyester mesh is available that offers superior tear and puncture resistance against animal claws. The magnetic strips are also manufactured to resist degradation from temperature fluctuations and maintain their magnetic strength over many years, ensuring a long operational lifespan, often exceeding 10-15 years under normal conditions.

Q3: Can magnetic window mesh be customized for non-standard window sizes or shapes?

Absolutely. Leading manufacturers offer comprehensive customization services. They can fabricate magnetic window mesh to precisely fit almost any window dimension or shape, including arched, circular, or unusually sized openings common in architectural projects. Customization also extends to mesh types (e.g., pollen-blocking, pet-resistant, security mesh), frame colors to match existing décor, and varying magnetic strengths to suit specific environmental conditions or user preferences. This flexibility makes them ideal for diverse B2B applications where standard sizes are insufficient.

Q4: What is the typical lead time and delivery process for bulk orders of magnetic window net?

Lead times for bulk orders of magnetic window net can vary depending on the order volume, level of customization, and current production schedule. Typically, standard bulk orders might have a lead time of 2-4 weeks, while highly customized or very large projects could extend to 6-8 weeks. Reputable manufacturers will provide a clear delivery schedule and logistics plan upon order confirmation. They usually offer various shipping options (sea freight, air freight) to optimize for cost and speed, and provide tracking information to ensure transparency throughout the delivery process. Clients are encouraged to discuss their specific project timelines during the quoting phase.

Q5: How easy is it to clean and maintain a magnetic screen window?

Maintenance for a magnetic screen window is exceptionally easy, one of its key user benefits. Due to its magnetic attachment, the screen can be effortlessly removed from the window frame. Once detached, it can be simply wiped down with a damp cloth or soft brush to remove dust and debris. For deeper cleaning, it can be gently rinsed with water and mild soap, then air-dried. Unlike fixed screens that are difficult to access and clean, the removable nature of the magnetic screen ensures thorough cleaning, contributing to better hygiene and extending the product's lifespan. This low-maintenance aspect makes it highly attractive for both residential and commercial facility management.

References and Further Reading:

- [1] Grand View Research. "Window Screen Market Size, Share & Trends Analysis Report By Material, By Application (Residential, Commercial), By Region, And Segment Forecasts, 2023 - 2030." Available at: https://www.grandviewresearch.com/industry-analysis/window-screen-market

- [2] ASTM International. "Standard Test Method for Operating Light-Exposure Apparatus (Fluorescent UV Condensation Type) for Exposure of Nonmetallic Materials." Available at: https://www.astm.org/g154-24.html

- [3] International Organization for Standardization. "ISO 9001:2015 - Quality management systems — Requirements." Available at: https://www.iso.org/standard/62085.html

- [4] UL Standards. "UL 94, the Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances Testing." Available at: https://ul.com/resources/ul-94-flammability-testing

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025