Авг . 12, 2025 04:20 Back to list

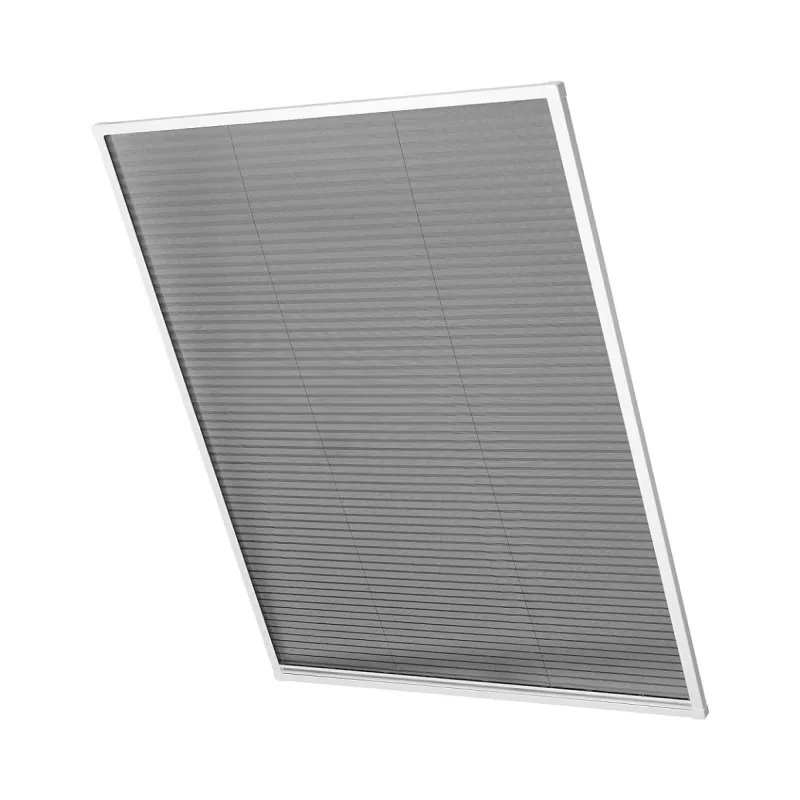

Premium Pleated Mesh Window Screens: Durable & Retractable

The Evolution and Excellence of Pleated Mesh Window Systems

In modern architectural design and construction, the demand for sophisticated, functional, and aesthetically pleasing fenestration solutions is continuously evolving. Among the innovations, the pleated mesh window stands out as a superior choice, offering unparalleled benefits over traditional screens. These systems are engineered not only to provide effective insect barriers but also to enhance ventilation, optimize natural light, and seamlessly integrate into diverse design aesthetics. Their unique accordion-fold design allows for compact retraction, preserving views and architectural integrity when not in use. This article delves deep into the technical intricacies, industry applications, and strategic advantages of advanced pleated mesh systems, providing B2B decision-makers with comprehensive insights into this innovative window solution. We explore the critical parameters, manufacturing excellence, and real-world performance metrics that underscore their value in contemporary building projects.

Unpacking Pleated Mesh Window Technology: Key Specifications and Parameters

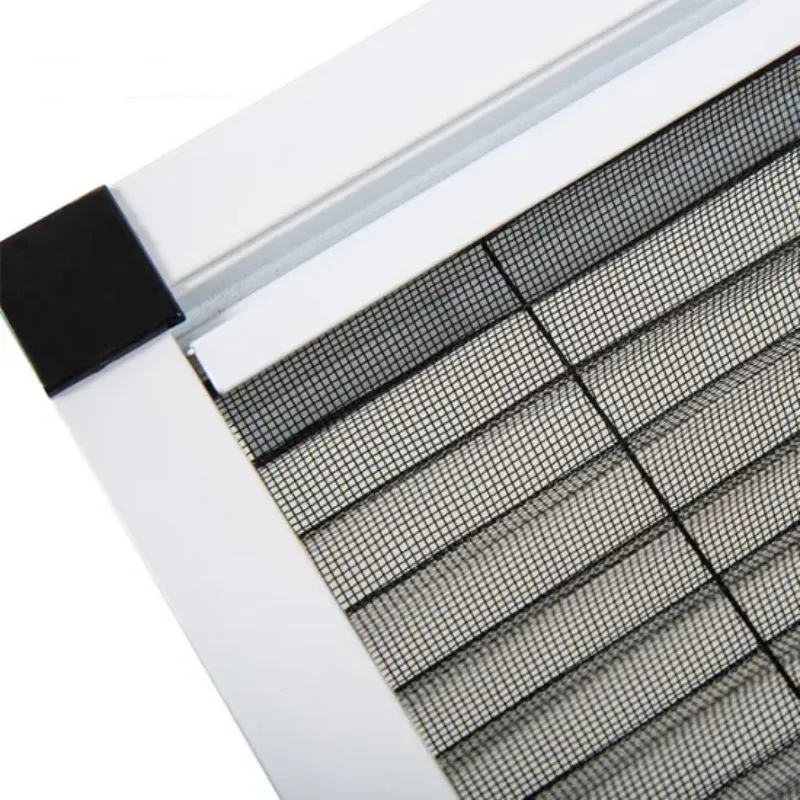

Understanding the technical specifications of a pleated mesh window is crucial for ensuring optimal performance and compatibility with specific project requirements. These systems are characterized by a range of parameters that influence their durability, functionality, and aesthetic integration. Key considerations include the mesh material, weave density, frame composition, and operational mechanisms. Advanced materials like high-strength polyester, fiberglass, or even specialized anti-bacterial coatings contribute significantly to longevity and resistance against environmental factors. Frame components, often crafted from robust aluminum alloys, undergo rigorous treatment to withstand corrosion and wear, ensuring the structural integrity of the entire system. Below is a comprehensive table detailing typical technical parameters that define high-quality pleated mesh systems available in the market.

| Parameter | Description | Standard Values/Range |

|---|---|---|

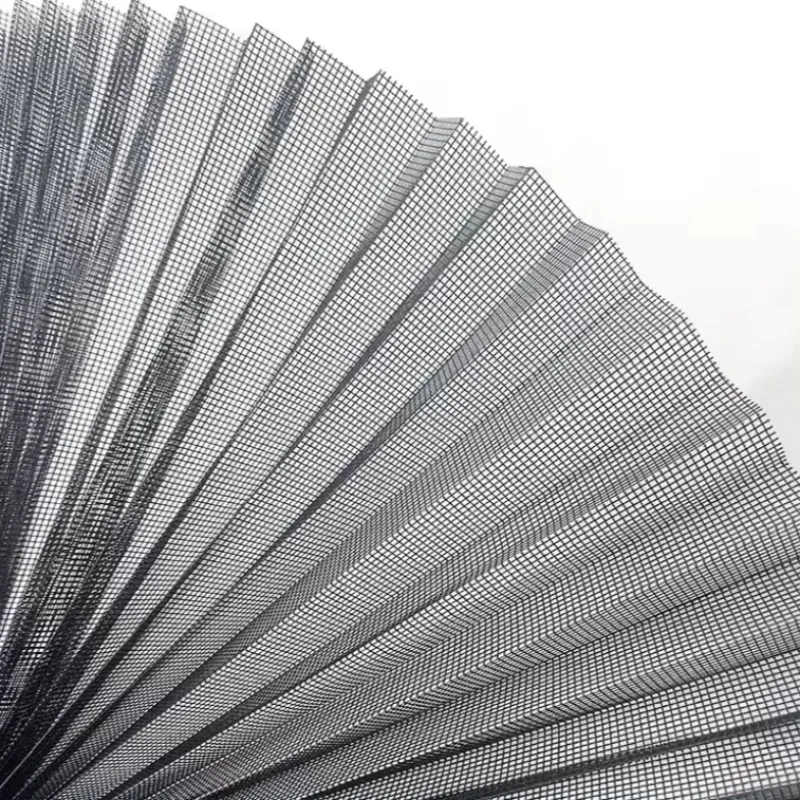

| Mesh Material | High-density polyester, fiberglass, PP mesh (UV resistant) | UV-stabilized, tear-resistant, mildew-proof |

| Mesh Pleat Depth | The depth of the pleats in the mesh fabric. | 15mm - 20mm (typical) |

| Frame Material | Extruded Aluminum Alloy (6063-T5) | Powder-coated, Anodized finishes available |

| Operating Mechanism | Smooth glide system, low-friction cords, magnetic catch | Manual (single/double pull), Motorized (optional) |

| UV Resistance | Ability to resist degradation from ultraviolet radiation | > 70% UV blocking (ISO 4892-2 standard compliant) |

| Wind Load Resistance | Capacity to withstand wind pressure without damage | Up to 30 m/s (dependent on size/installation) |

| Service Life | Expected operational lifespan under normal conditions | 10+ years (with proper maintenance) |

| Color Options | Range of available colors for mesh and frame | Standard RAL colors, custom options for frame; Black, Grey mesh |

The Advanced Manufacturing Process of Pleated Mesh Window Systems

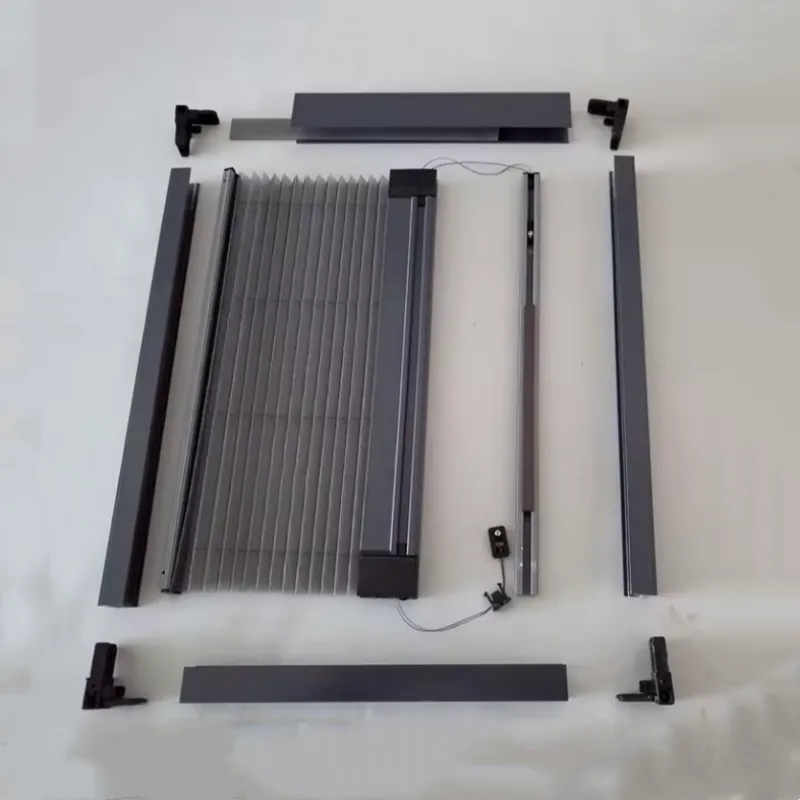

The production of a high-quality pleated mesh for windows involves a sophisticated multi-stage manufacturing process, ensuring precision, durability, and aesthetic appeal. This process begins with the careful selection of raw materials, which are critical to the final product's performance. For the mesh itself, UV-stabilized polyester or durable fiberglass yarns are chosen for their resilience against environmental degradation and excellent tear resistance. The frame components are typically precision-extruded aluminum alloys (e.g., 6063-T5), known for their strength-to-weight ratio and corrosion resistance. These extrusions undergo CNC machining to achieve exact dimensions and smooth finishes, followed by surface treatments like powder coating or anodizing, which enhance durability and offer a wide range of aesthetic finishes.

The core of the manufacturing process lies in the pleating of the mesh and the integration of the components. Automated machinery precisely folds the mesh into its distinctive pleated pattern, ensuring uniform pleat depth and spacing, which is crucial for smooth operation and compact retraction. Simultaneously, high-precision injection molding is used for producing critical plastic components like end caps, handles, and connectors, ensuring dimensional accuracy and robust mechanical properties. Adherence to international standards such as ISO 9001 for quality management and ANSI/UL standards for specific material properties is paramount at every stage. Comprehensive quality control checks, including material tensile strength tests, UV exposure durability tests, and cycle testing of the retraction mechanism, are performed to guarantee a service life often exceeding 10 years, even in demanding environments such as coastal regions or industrial facilities.

Technical Advantages and Diverse Application Scenarios

The technical prowess of a pleated mesh window translates directly into significant advantages for various applications, ranging from residential complexes to highly specialized industrial environments. One primary advantage is superior ventilation without compromising insect protection. The fine mesh, while robust, allows for excellent airflow, contributing to energy efficiency by reducing reliance on air conditioning. Its pleated design ensures minimal obstruction of views and light when retracted, maintaining the aesthetic integrity of the window or doorway. Furthermore, the inherent durability of the materials used, combined with meticulous manufacturing, grants these systems exceptional resistance to corrosion, particularly vital in humid or coastal climates, and resilience against physical wear and tear.

In industrial settings, such as petrochemical plants, metallurgy facilities, or water treatment centers, maintaining clean environments while ensuring natural airflow is critical. Pleated mesh for windows offers a robust solution for these sectors, preventing the ingress of dust, debris, and insects that could compromise operations or product quality. Their anti-corrosion properties make them ideal for areas exposed to harsh chemicals or extreme weather. For residential and commercial buildings, they provide a sleek, modern alternative to traditional screens, enhancing property value and occupant comfort. They are particularly suitable for large openings like bifold doors, sliding doors, and oversized windows, where traditional screens might be cumbersome or aesthetically unappealing, offering ease of use and long-term performance benefits.

Strategic Sourcing: Manufacturer Comparison and Customization Solutions

Choosing the right manufacturer for your pleated window mesh needs is a critical decision that impacts project success, long-term performance, and overall cost-efficiency. Key factors to consider during manufacturer comparison include adherence to quality standards (e.g., ISO, CE certifications), depth of customization capabilities, historical performance in similar projects, and post-sales support. Leading manufacturers differentiate themselves through advanced material science, proprietary operating mechanisms that ensure smooth and durable retraction, and a strong track record of successful installations. It's advisable to assess their portfolio, request detailed technical datasheets, and ideally, visit their manufacturing facilities or review third-party audit reports.

Customization is often a paramount requirement in B2B projects, from unique size specifications for oversized architectural openings to specific color matching for brand consistency or aesthetic integration. A capable manufacturer of pleated mesh window systems should offer extensive customization options, including:

- Dimensioning: Tailored widths and heights to fit any opening precisely.

- Frame Finishes: Custom RAL powder coating, anodizing, or wood grain finishes.

- Mesh Type: Options for increased UV resistance, pet-resistant mesh, or specialized anti-pollen meshes.

- Operation: Manual or integrated motorized solutions for smart home systems.

- Configurations: Single-panel, double-panel (centre opening), or multi-panel systems.

A thorough evaluation of these capabilities will ensure that the selected pleated mesh solution not only meets immediate technical specifications but also aligns with long-term strategic objectives and aesthetic demands.

Building Trust: Quality Assurance, Client Support, and FAQs

Trust is paramount in B2B relationships, particularly when dealing with long-term infrastructure components like pleated mesh window systems. Our commitment to Authoritativeness and Trustworthiness is demonstrated through stringent quality control, robust client support, and transparent communication. All products adhere to international quality management systems, including ISO 9001:2015, ensuring consistent manufacturing excellence. Regular independent audits and in-house laboratory testing for material strength, UV stability, and operational cycle endurance guarantee that our pleated mesh for windows meets and often exceeds industry benchmarks. With over 20 years of experience in the fenestration industry, our expertise is backed by a portfolio of successful projects and partnerships with leading architects and builders worldwide.

Frequently Asked Questions (FAQs)

-

Q: What is the typical lead time for custom pleated mesh window orders?

A: For standard orders, lead time is typically 3-4 weeks from order confirmation. Custom or large-volume projects may require 5-8 weeks, depending on complexity and material availability. We provide clear delivery schedules upon order confirmation. -

Q: What warranty is provided with your pleated mesh window systems?

A: We offer a comprehensive 5-year warranty on all manufacturing defects for our pleated window mesh systems. This covers components such as mesh integrity, frame structure, and operational mechanisms under normal use conditions. Specific project warranties can be negotiated for large-scale applications. -

Q: How do pleated mesh windows contribute to energy efficiency?

A: By allowing superior airflow and natural ventilation, pleated mesh window systems reduce the reliance on air conditioning, particularly during milder weather. This leads to significant energy savings and a reduced carbon footprint for buildings. -

Q: Is professional installation required for pleated mesh windows?

A: While our systems are designed for straightforward installation, professional installation is highly recommended to ensure optimal performance, proper alignment, and full warranty coverage. We can provide detailed installation guides and offer technical support.

Conclusion: A Strategic Investment for Modern Fenestration

The adoption of pleated mesh window systems represents a strategic investment in modern fenestration solutions, offering a compelling blend of functionality, durability, and aesthetic appeal. Their advanced design and meticulous manufacturing processes ensure superior performance in diverse environments, from residential comfort to stringent industrial requirements. By providing exceptional ventilation, robust insect protection, and seamless integration with architectural designs, these systems address critical needs for contemporary building projects. As B2B decision-makers evaluate optimal solutions, considering the long-term benefits in terms of energy efficiency, reduced maintenance, and enhanced occupant well-being, the value proposition of pleated mesh technology becomes increasingly clear. Choosing a reputable manufacturer with a strong commitment to quality, customization, and comprehensive support is key to realizing the full potential of these innovative window barriers.

References

- International Organization for Standardization (ISO). ISO 9001:2015 Quality Management Systems – Requirements.

- American National Standards Institute (ANSI). ANSI/UL Standards for Safety Testing of Materials.

- Building Performance Institute. Impact of Natural Ventilation on Energy Consumption.

- Architectural Digest. Trends in Sustainable Building Materials and Window Technologies.

- Fenestration & Glazing Industry Alliance (FGIA). Guidelines for Performance of Insect Screens.

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025