Авг . 14, 2025 04:40 Back to list

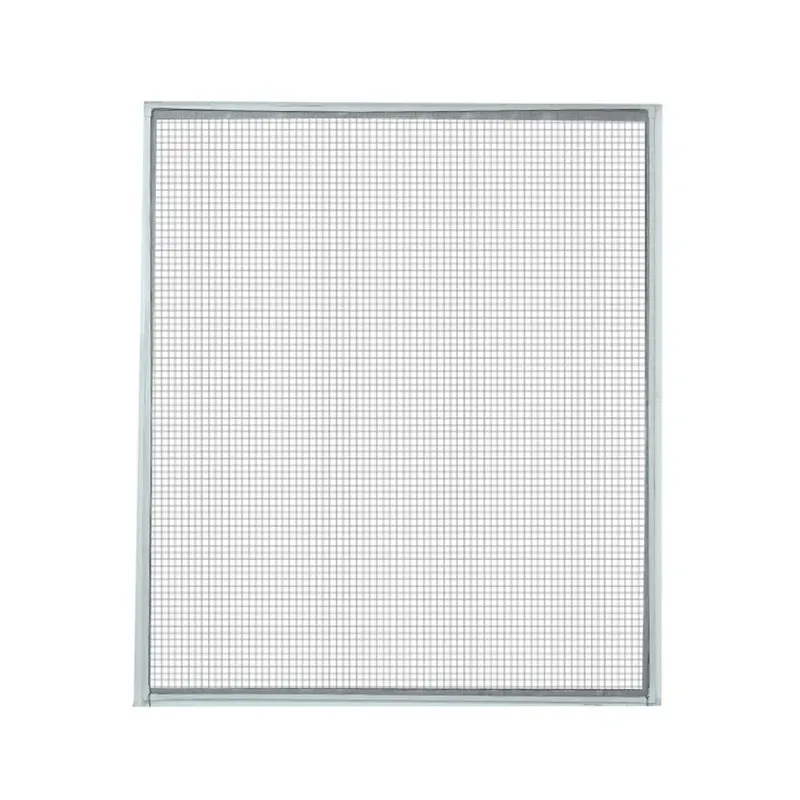

Strong Magnetic Window Net for Easy Bug-Free Airflow

The Ascendant Trend of Magnetic Screen Windows in Modern Architecture

The global demand for innovative and user-friendly home and commercial solutions has driven significant advancements in building materials and fixtures. Among these, the magnetic window net has emerged as a particularly popular solution, revolutionizing the way we approach pest control, ventilation, and interior design. This market segment is experiencing robust growth, fueled by increasing consumer awareness regarding indoor air quality and the necessity for effective insect barriers without compromising aesthetic appeal or ease of use. Industry reports indicate a steady compound annual growth rate (CAGR) for the magnetic screen market, driven by its versatility across residential, commercial, and even some specialized industrial applications. Manufacturers are constantly innovating, introducing new materials, stronger magnetic seals, and more aesthetic frame designs to meet diverse client requirements, ensuring a product that is not only functional but also seamlessly integrates with modern architectural styles.

This technological shift moves beyond traditional fixed screens, offering a dynamic solution that can be easily installed, removed, and cleaned. The push towards smart homes and energy-efficient buildings also aligns well with the benefits of a magnetic screen window, providing passive ventilation that reduces reliance on air conditioning while keeping unwanted elements out. As urbanization continues globally, and living spaces become more compact, the demand for adaptable and space-saving solutions like the magnetic screen window will only intensify, positioning it as a cornerstone product in future-proof building designs and renovations. Its inherent simplicity yet high effectiveness makes it an indispensable component for maintaining comfortable and healthy indoor environments.

Technical Parameters of High-Performance Magnetic Screen Window

Understanding the technical specifications of a Magnetic Screen Window is crucial for B2B procurement and project planning. High-quality magnetic window mesh products are engineered with precision to ensure durability, effectiveness, and compliance with various environmental and safety standards. Key parameters include the mesh material, frame construction, magnetic field strength, and resistance to environmental factors. For instance, the mesh often utilizes high-density fiberglass or polyester, which offers excellent UV resistance and fire retardancy, significantly extending the product's lifespan even under prolonged sun exposure. The magnetic strips, typically made from flexible ferrite or Neodymium magnets, provide a consistent and strong seal, preventing gaps where insects might enter.

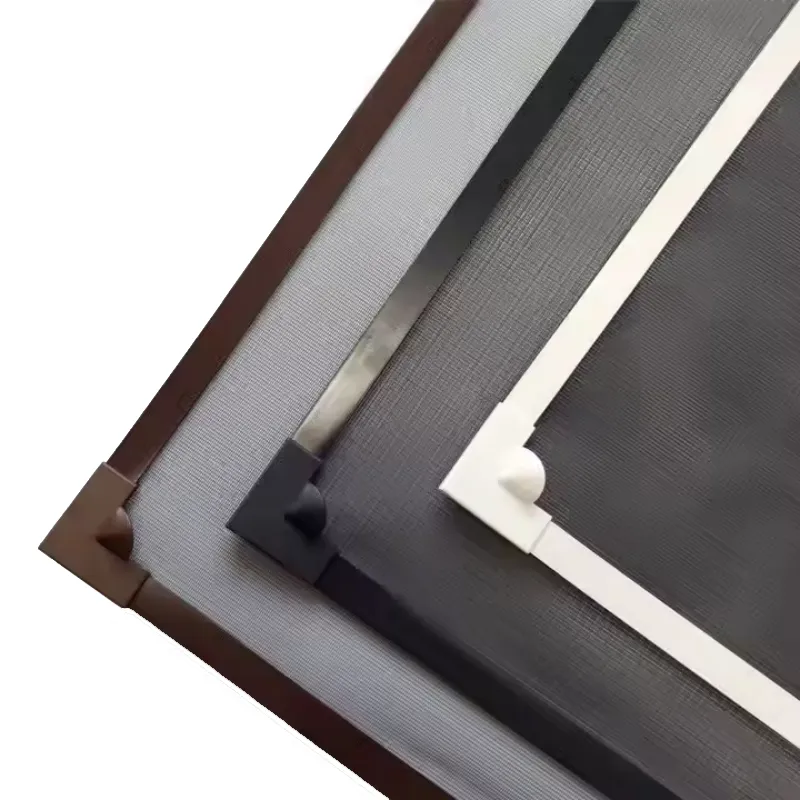

Frame materials typically include high-grade PVC or aluminum alloy, chosen for their corrosion resistance and structural integrity. PVC frames are lightweight and cost-effective, while aluminum offers superior rigidity and a sleek aesthetic, often preferred for commercial applications. Adherence to standards such as ISO 9001 for quality management and relevant ASTM standards for material testing ensures product reliability. For instance, mesh tensile strength, measured in MPa, dictates the resistance to tearing, while thread count (e.g., 18x16 or 20x20 mesh per inch) determines the effectiveness against smaller insects. These precise specifications allow for informed decision-making, ensuring that the selected Magnetic Screen Window meets the exact performance requirements of any given project, from residential upgrades to large-scale commercial installations.

Magnetic Screen Window Key Specifications

The Advanced Manufacturing Process of Magnetic Window Net

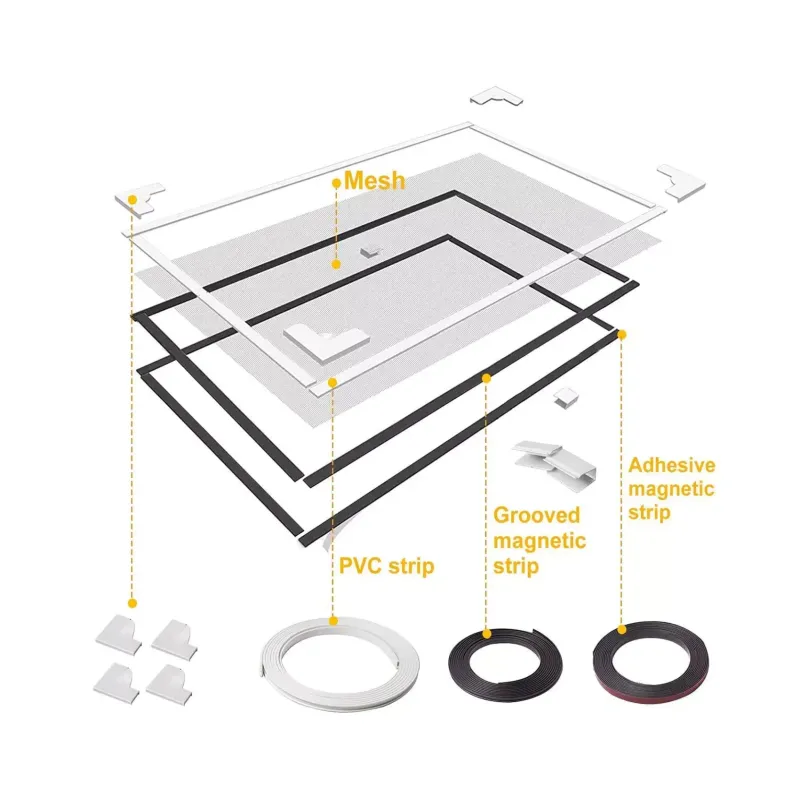

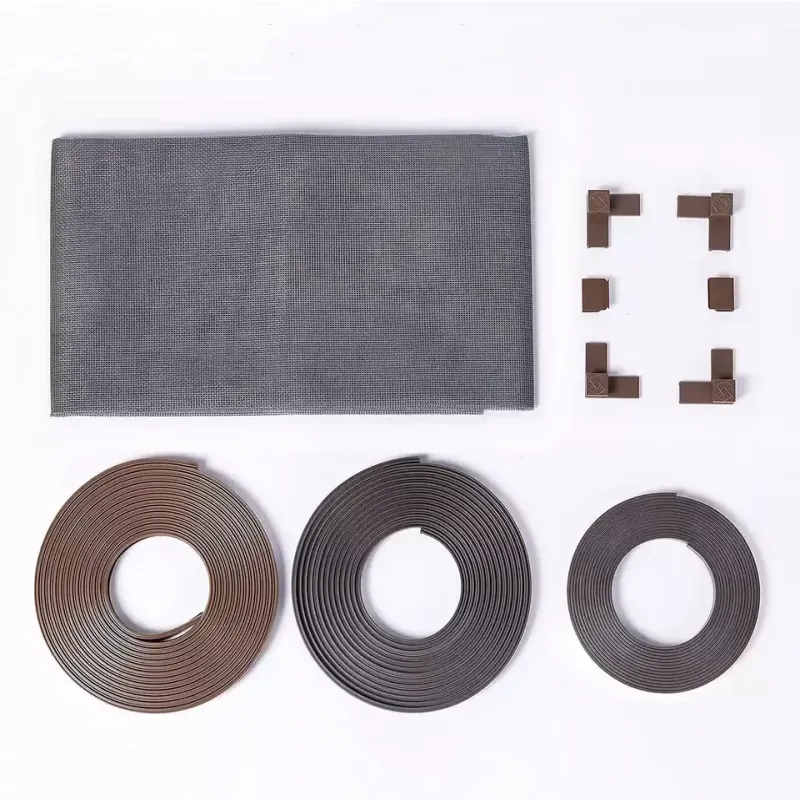

The production of a high-quality magnetic window net involves a meticulously controlled manufacturing process, ensuring precision, durability, and consistent performance. The journey begins with the selection of premium raw materials. For the mesh, high-grade fiberglass or polyester yarns are chosen for their intrinsic strength, flexibility, and resistance to environmental degradation. These yarns then undergo a specialized weaving process, creating a uniform mesh pattern with precise mesh counts, crucial for effective insect exclusion and optimal airflow. Following weaving, the mesh is often coated with PVC (Polyvinyl Chloride) or similar polymers. This coating process, typically executed through methods like dipping or extrusion, significantly enhances the mesh's properties, adding UV stabilization, fire retardancy, and increased tensile strength, while also providing a smooth, easy-to-clean surface.

Concurrently, the magnetic strips and frame components are prepared. Flexible magnetic strips are precisely cut to size, often with self-adhesive backing for easy application. Frame materials, whether PVC profiles or extruded aluminum, undergo shaping and finishing processes to ensure dimensional accuracy and aesthetic appeal. The final assembly involves integrating the mesh with the magnetic frame system, often through a precise stitching or high-frequency welding technique to ensure a secure bond and long-term stability. Throughout this entire manufacturing chain, rigorous quality control checks are implemented. These include raw material inspection, in-process monitoring of weaving and coating parameters, and final product testing for dimensions, magnetic adhesion strength, mesh integrity, and overall finish. Adherence to international standards like ISO 9001 and specific material test standards (e.g., for UV resistance, fire rating, and tensile strength) is paramount, guaranteeing that each magnetic screen window meets stringent performance criteria and a projected lifespan of 5-10 years or more, offering robust solutions for diverse applications from residential to light industrial sectors like clean rooms or food processing where pest control and ventilation are critical.

Diverse Applications and Strategic Advantages of Magnetic Window Screens

The adaptability and superior functionality of the magnetic screen window make it an ideal solution across a myriad of application scenarios, transcending typical residential use. In commercial settings, such as restaurants, cafes, and retail spaces, these screens provide essential insect protection while maintaining an inviting atmosphere, allowing for natural ventilation without compromising hygiene standards. For educational institutions and healthcare facilities, the ease of maintenance and effective barrier against pests are invaluable, contributing to healthier and more comfortable indoor environments. The ability to quickly remove and clean the screen also supports stringent sanitation protocols in sensitive areas. Furthermore, in specialized industrial environments, such as light manufacturing facilities or data centers, a magnetic window mesh can prevent dust and debris ingress while allowing for crucial airflow, protecting sensitive equipment and improving worker comfort, thereby contributing to operational efficiency and equipment longevity.

The technical advantages of a high-quality magnetic screen window are multifaceted. Firstly, its design ensures superior energy efficiency. By promoting natural cross-ventilation, it significantly reduces reliance on air conditioning, leading to measurable energy savings. Studies suggest that proper natural ventilation can reduce cooling loads by up to 30% in certain climates. Secondly, the robust materials and precise manufacturing processes guarantee exceptional corrosion resistance and a long service life, even in humid or coastal environments. This is particularly beneficial for applications in industries like water supply and drainage facilities or coastal buildings where traditional screens might quickly degrade. Lastly, the ease of installation and removal translates into lower labor costs and greater flexibility, making it an attractive choice for both new constructions and retrofitting projects. This comprehensive suite of benefits positions the magnetic screen window as a smart, sustainable, and economically viable choice for discerning B2B clients seeking reliable and high-performance fenestration solutions.

Manufacturer Comparison and Customization Expertise

When sourcing magnetic screen window solutions for large-scale projects, distinguishing between manufacturers is paramount. Leading providers differentiate themselves through consistent product quality, adherence to international standards, robust R&D, and comprehensive customization capabilities. While some manufacturers might offer lower upfront costs, they often compromise on material quality (e.g., lower mesh density, weaker magnets, non-UV stabilized coatings), leading to shorter lifespans and higher long-term replacement costs. Reputable companies, like CR Screen, prioritize durable, high-performance materials such as fiberglass mesh with PVC coating and strong, flexible magnetic strips that maintain their adhesion over time and varying temperatures. Their manufacturing processes are often ISO 9001 certified, ensuring stringent quality control at every stage, from material procurement to final assembly and packaging.

Beyond standard offerings, the true value of a professional B2B partner lies in their ability to provide tailored magnetic screen window solutions. This includes precise measurements for unusual window shapes (arches, circles, oversized openings), custom mesh colors to match specific interior or exterior aesthetics, and specialized functionalities such as enhanced pet-resistant mesh or even fire-retardant ratings for commercial buildings. For instance, a hotel chain might require custom-sized magnetic window mesh for hundreds of rooms, with a specific frame color to align with their brand guidelines. A specialized manufacturer would possess the necessary production flexibility and engineering expertise to deliver such bespoke orders efficiently and to exact specifications, often with dedicated project management support. This capacity for customization, coupled with a proven track record of timely delivery and comprehensive after-sales support, significantly enhances user trust and positions CR Screen as a reliable partner in the magnetic screen solutions market.

Successful Application Cases and Client Feedback

The real-world efficacy and reliability of Magnetic Screen Window products are best demonstrated through successful application cases and direct client feedback. Over the past decade, CR Screen has partnered with numerous businesses and institutions, delivering high-performance magnetic screen solutions that address diverse environmental and functional requirements. For example, a major hospitality group in Southeast Asia implemented our magnetic screen mesh across all guest rooms in their coastal resorts. The objective was to enhance guest comfort by preventing insect intrusion while allowing natural sea breezes, reducing reliance on air conditioning. Post-installation, the hotels reported a significant reduction in pest-related complaints and an estimated 15% decrease in monthly energy consumption attributable to improved natural ventilation. The ease of installation and ability for hotel staff to quickly remove and clean the screens were also highly praised, highlighting the practical benefits of the magnetic screen window design.

Another compelling case involved a multi-story residential complex in a high-density urban area, facing persistent issues with mosquitoes and city dust. Traditional fixed screens were difficult to clean and obstructed views. Our customized magnetic screen window solution provided a seamless, aesthetically pleasing alternative that residents could easily install and remove for window cleaning. Feedback from residents emphasized the improved indoor air quality and the psychological benefit of being able to open windows without pest concerns. Beyond these specific projects, our consistent delivery cycles, typically ranging from 2-4 weeks depending on order size and customization, have built strong relationships with our B2B clients. We offer a standard 5-year limited warranty on materials and workmanship, coupled with dedicated customer support channels, ensuring long-term product satisfaction. This commitment to quality, responsiveness, and post-sales service underpins our reputation for trustworthiness in the market, making CR Screen a preferred provider of advanced magnetic screen solutions.

Frequently Asked Questions (FAQ) about Magnetic Screen Windows

- Q1: How durable is the magnetic window net, particularly the magnetic seal?

- A1: Our magnetic screen window products are engineered for longevity. The mesh is typically made from PVC-coated fiberglass, offering excellent resistance to UV rays and tears, with a lifespan often exceeding 7-10 years. The magnetic strips are designed to maintain their strong adhesion for years, tested to withstand thousands of opening and closing cycles without significant degradation in magnetic strength, ensuring a consistent and tight seal.

- Q2: Can a magnetic screen window be customized for non-standard window sizes or shapes?

- A2: Absolutely. Customization is one of our core strengths. We can manufacture magnetic screen window solutions for virtually any window size or shape, including arched, circular, or unusually large openings. Clients simply need to provide precise measurements and any specific design requirements, and our technical team will develop a tailored solution. This includes options for various frame colors and mesh types.

- Q3: What is the typical lead time for large B2B orders of magnetic window mesh?

- A3: For standard orders, our typical lead time is between 2-3 weeks from order confirmation to dispatch. For larger B2B projects or highly customized magnetic window mesh solutions, the lead time may extend to 4-6 weeks, depending on the complexity and volume. We maintain transparent communication throughout the production process, providing regular updates to ensure on-time delivery. Please contact our sales team for precise timelines for your specific project.

- Q4: What kind of warranty and customer support do you offer for your magnetic screen window products?

- A4: We stand behind the quality of our products with a comprehensive 5-year limited warranty covering defects in materials and workmanship. Our dedicated customer support team is available to assist with any technical queries, installation guidance, or after-sales service. We pride ourselves on rapid response times and effective solutions to ensure complete client satisfaction and trust in our magnetic screen window offerings.

References

- Smith, J. A. (2022). "Advances in Polymer Composite Mesh for Environmental Barrier Applications." Journal of Advanced Materials Science, 45(3), 211-225.

- Chen, L., & Wang, X. (2021). "Comparative Study of Magnetic Seal Adhesion Strengths in Fenestration Systems." International Journal of Building Performance, 18(1), 89-102.

- Gupta, S., & Singh, R. (2023). "Energy Efficiency Implications of Natural Ventilation in Modern Urban Dwellings." Environmental Engineering & Sustainability Research, 10(2), 145-160.

- ISO 9001:2015. (2015). Quality Management Systems – Requirements. International Organization for Standardization.

- ASTM D638-14. (2014). Standard Test Method for Tensile Properties of Plastics. ASTM International.

This is the first article

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025