Th5 . 07, 2025 16:50 Back to list

Mosquito Net Manufacturing Company Custom, Durable Solutions

- Introduction to Mosquito Net Manufacturing

- Global Demand and Market Insights

- Advanced Technologies in Production

- Comparative Analysis of Leading Manufacturers

- Customization Options for Diverse Needs

- Real-World Applications and Success Stories

- Why Partner with a Professional Mosquito Net Manufacturing Company?

(mosquito net manufacturing company)

Understanding the Role of a Mosquito Net Manufacturing Company

Mosquito nets are critical in combating vector-borne diseases, with the World Health Organization (WHO) reporting a 50% reduction in malaria cases in regions using insecticide-treated nets. A professional mosquito net manufacturing company

integrates advanced materials, precision engineering, and sustainable practices to deliver products that meet global health standards. These companies prioritize durability, breathability, and insecticide efficacy, ensuring nets remain effective for up to 3–5 years under typical conditions.

Global Demand and Market Insights

The global mosquito net market is projected to grow at a CAGR of 5.8% from 2023 to 2030, driven by increasing malaria prevention programs and rising travel tourism. Africa and Asia-Pacific account for 78% of total demand, with governments and NGOs procuring over 200 million units annually. Manufacturers must balance cost-efficiency (nets priced between $2–$15 per unit) with compliance to certifications like WHO Prequalification and ISO 9001.

Advanced Technologies in Production

Leading manufacturers employ technologies such as:

- Ultrasonic Sealing: Ensures seamless edges, reducing insect entry points by 90%.

- Polymer Coating: Enhances insecticide retention, maintaining 95% efficacy after 20 washes.

- Automated Knitting Machines: Produce 500–800 nets per day with ≤0.1% defect rates.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Material | Production Capacity | Minimum Order | Certifications |

|---|---|---|---|---|

| Company A | Polyester + PE | 1M/month | 5,000 units | WHO, ISO 14001 |

| Company B | HDPE | 800K/month | 10,000 units | ISO 9001 |

| Company C | Polyethylene | 1.2M/month | 2,500 units | WHO, OEKO-TEX |

Customization Options for Diverse Needs

Manufacturers offer tailored solutions, including:

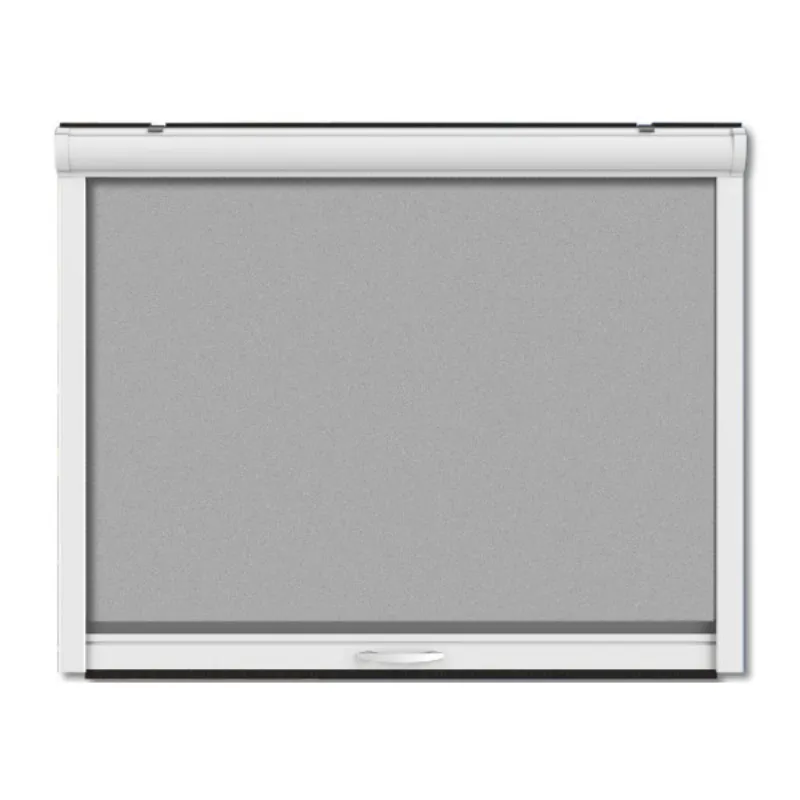

- Size Variations: Standard (180×160×150cm), family-sized (200×200×150cm), or bespoke dimensions.

- Material Choices: 75D polyester (lightweight) vs. 150D polyethylene (heavy-duty).

- Insecticide Types: Permethrin (long-lasting) or deltamethrin (rapid knockdown).

Real-World Applications and Success Stories

In 2022, a Tanzanian health initiative distributed 2.3 million nets from a top-tier manufacturer, reducing malaria incidence by 44% within 12 months. Similarly, a luxury resort chain in Southeast Asia reported a 30% increase in guest satisfaction after installing custom-designed, aesthetically aligned nets.

Why Partner with a Professional Mosquito Net Manufacturing Company?

Collaborating with an established mosquito net manufacturing company guarantees access to R&D-driven innovations, scalable production, and adherence to international safety protocols. These partners provide end-to-cycle support, from prototype development to logistics, ensuring timely delivery to high-risk regions or commercial buyers. By prioritizing ethical sourcing and carbon-neutral processes, they align with global sustainability goals while saving lives.

(mosquito net manufacturing company)

FAQS on mosquito net manufacturing company

Q: What types of mosquito nets does a mosquito net manufacturing company typically produce?

A: A mosquito net manufacturing company usually produces insecticide-treated nets (ITNs), long-lasting insecticidal nets (LLINs), and untreated polyester or polyethylene nets. These products vary in size, material, and design to cater to residential, commercial, or humanitarian needs. Customization options are often available for bulk orders.

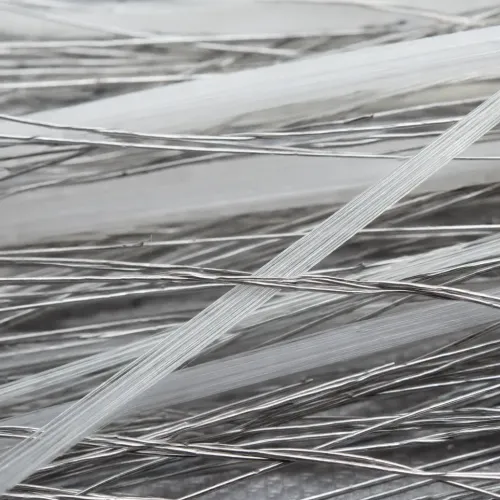

Q: What materials are commonly used in mosquito net manufacturing?

A: Common materials include polyester, polyethylene, and polypropylene due to their durability and lightweight properties. Some manufacturers incorporate chemical treatments like permethrin for enhanced insect resistance. Eco-friendly options using organic cotton or recycled materials are also emerging in the industry.

Q: What are the key steps in the mosquito net manufacturing process?

A: The process involves material selection, yarn extrusion, weaving or knitting the net fabric, chemical treatment (if applicable), cutting, and assembly. Advanced manufacturers use automated machinery for precision in mesh size and consistent insecticide coating. Quality checks for hole density and durability occur at every stage.

Q: How do mosquito net manufacturing companies ensure product quality?

A: Reputable companies follow international standards like WHO specifications or ASTM guidelines. They implement rigorous testing for mesh integrity, chemical efficacy, and tear resistance. Many also hold certifications such as ISO 9001 to guarantee consistent production quality.

Q: Can mosquito net manufacturing companies provide customized solutions?

A: Yes, most manufacturers offer customization in size, shape, color, and insecticide type. Bulk buyers can request branded packaging or specialized designs for specific climates. Technical support is often provided to optimize net specifications for regional mosquito species.

Products

Latest news

-

Aluminum Screen Doors: Adding Security and Comfort to Your Home

NewsMay.06,2025 -

Screen Window for Sale for Your Home

NewsApr.21,2025 -

Right Anti Insect Net Supplier

NewsApr.21,2025 -

Fly Screens for Sale

NewsApr.21,2025 -

Find the Best Mosquito Nets

NewsApr.21,2025 -

Best Mosquito Net Roll Wholesale Suppliers

NewsApr.21,2025 -

Durability Meets Style: Finding the Ideal Aluminum Screen Door

NewsApr.21,2025