আগস্ট . 08, 2025 06:00 Back to list

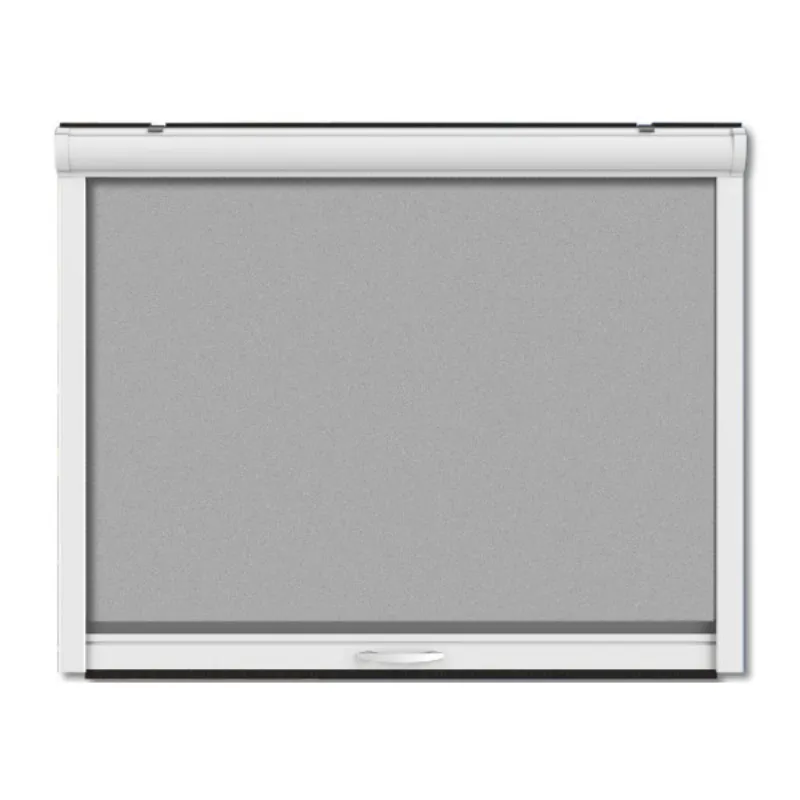

Roller Mosquito Screens: Retractable & Roll Up Anti-Mosquito Window

Embracing Modern Living with Advanced Roller Mosquito Screens

In an increasingly interconnected world, where the comfort and safety of our homes are paramount, innovative solutions like the roller mosquito screen have become indispensable. Moving beyond traditional fixed screens, these sophisticated systems offer unparalleled protection against insects while maintaining aesthetic appeal and maximizing ventilation. This comprehensive guide delves into the world of modern `anti mosquito window` solutions, specifically focusing on the advanced capabilities of the Roller Screen Window from CRScreen, available at https://www.crscreen.com/roller-screen-window.html. We will explore industry trends, technical specifications, manufacturing precision, and the myriad of benefits these `roll up window screens` bring to diverse applications.

Industry Trends and Market Dynamics: The Rise of Retractable Screens

The global demand for effective and discreet insect protection is soaring, driven by factors such as climate change influencing mosquito populations, increased health awareness regarding vector-borne diseases, and a growing preference for smart, minimalist home designs. The traditional fixed window screen, while effective, often compromises views, restricts natural light, and can be cumbersome to clean or maintain. This has paved the way for the significant growth of the retractable screen market, with roller mosquito screen solutions leading the charge.

Recent market analyses indicate that the global window screen market is projected to reach approximately $13.5 billion by 2030, growing at a Compound Annual Growth Rate (CAGR) of 6.8% from 2023. A substantial portion of this growth is attributed to the retractable and integrated screen segments, as consumers and businesses increasingly seek solutions that blend seamlessly with modern architecture and offer enhanced user experience. The convenience of `roll up window screens` that disappear when not needed, coupled with advancements in mesh technology, makes them a preferred choice for discerning customers.

Technical Parameters and Product Specifications of Roller Screen Window

The performance and durability of any roller mosquito screen are rooted in its technical specifications. The Roller Screen Window from CRScreen is engineered with precision, utilizing high-quality materials and innovative design to deliver superior protection and longevity. Understanding these parameters is crucial for appreciating the product's value proposition.

Key Components & Materials:

- Frame Material: Typically high-grade extruded aluminum alloy, such as 6063-T5. This aerospace-grade aluminum offers exceptional strength-to-weight ratio, excellent corrosion resistance (especially when powder-coated), and maintains structural integrity against deformation. Its lightweight nature also ensures smooth operation of the retractable mechanism.

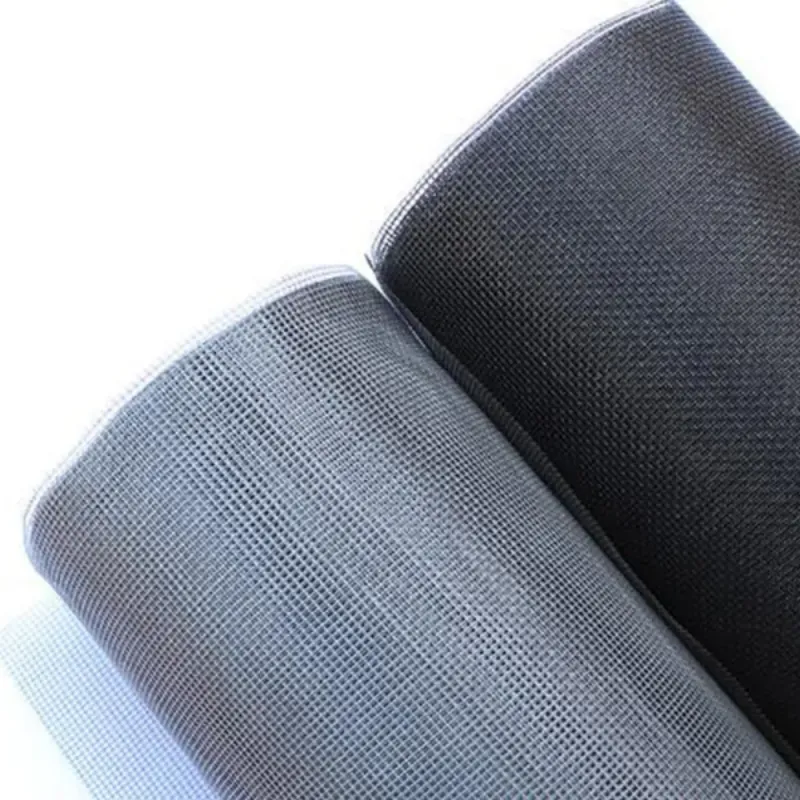

- Mesh Material: The most common and effective material is PVC-coated fiberglass mesh. This material is known for its excellent transparency, allowing clear views while effectively blocking insects. It is also UV-resistant, preventing degradation and fading from prolonged sun exposure, and fire-retardant. Standard mesh counts are typically 18x16 or 20x20 meshes per square inch, providing optimal balance between airflow and insect exclusion. For specific needs, pet-resistant polyester mesh or fine-weave pollen-blocking meshes are available.

- Operating Mechanism: Advanced spring-loaded retraction systems, often coupled with soft-close mechanisms, ensure smooth, quiet, and controlled operation. Motorized options with remote control or smart home integration capabilities are also popular, enhancing convenience.

- Sealing: High-quality brush seals and magnetic strips along the frame perimeter ensure a complete, gap-free seal, preventing even the smallest insects from entering.

Roller Mosquito Screen Key Parameters (CRScreen Roller Screen Window)

| Parameter | Specification | Benefit |

|---|---|---|

| Frame Material | 6063-T5 Extruded Aluminum Alloy | Superior strength, corrosion resistance, lightweight. |

| Mesh Material | PVC-Coated Fiberglass (Standard: 18x16 mesh/inch) | High transparency, UV-resistant, fire-retardant, durable. |

| Operating Mechanism | Spring-loaded with Soft-close/Optional Motorized | Smooth, quiet, controlled retraction; enhanced convenience. |

| Maximum Dimensions | Up to 1.8m (Width) x 2.5m (Height) per single unit (custom sizes available) | Accommodates large window openings. |

| UV Resistance | >70% UV Blockage for Mesh | Protects interiors from sun damage, extends screen life. |

| Wind Load Resistance | Up to 35-40 mph (approx. 56-64 km/h) | Withstands moderate to strong winds without damage. |

| Corrosion Resistance | Salt Spray Test (ASTM B117) - Exceeds 1000 hours (for coated aluminum) | Ideal for coastal or high-humidity environments. |

| Lifespan Expectancy | 10-15 years under normal operating conditions | Long-term, reliable performance. |

| Maintenance | Low; simple wipe-down cleaning | Easy to keep clean and functional. |

Industry Terminology Explained:

- Mesh Count: Refers to the number of threads per inch in both warp and weft directions. An 18x16 mesh count means there are 18 threads in one direction and 16 in the perpendicular direction, crucial for effective insect barrier and airflow.

- Denier: A unit of measurement for the linear mass density of fibers. While more common for textiles, understanding fiber thickness influences mesh strength and durability.

- Tensile Strength: The maximum stress a material can withstand while being stretched or pulled before breaking. High tensile strength in mesh material ensures resistance to tearing and puncturing.

- Corrosion Resistance: The ability of a material to resist deterioration caused by chemical reactions with its environment, particularly important for outdoor applications and humid climates.

Precision Manufacturing Process of Roller Screen Window

The superior quality and reliability of the CRScreen `Roller Screen Window` are a direct result of a meticulously controlled and technologically advanced manufacturing process. Each stage is designed to meet stringent quality benchmarks, ensuring every roller mosquito screen delivers consistent performance.

Detailed Manufacturing Workflow:

- Aluminum Profile Extrusion & Treatment:

- High-purity 6063 aluminum billets are heated and extruded through dies to form precise frame profiles (e.g., side rails, housing cassette, bottom bar). This process ensures uniform dimensions and structural integrity.

- Profiles undergo T5 temper treatment (artificial aging) to enhance hardness and strength.

- Surface treatment, typically powder coating, follows. This involves electrostatic application of dry powder paint, which is then cured under heat to form a durable, corrosion-resistant finish available in various colors. This step significantly boosts the `anti mosquito window`'s longevity and aesthetic appeal, offering superior protection against environmental elements compared to conventional painting.

- Mesh Weaving & Coating:

- High-strength fiberglass yarns are precisely woven into mesh fabric on automated looms, ensuring consistent mesh count and weave patterns.

- The woven mesh then undergoes a PVC coating process, where it's immersed in a liquid PVC solution and heat-treated. This coating provides UV resistance, increases durability, makes the mesh waterproof, and ensures its longevity against environmental degradation. This is crucial for the performance of `roll up window screens`.

- Quality checks for mesh integrity, uniformity, and coating thickness are performed.

- Component Injection Molding & Machining:

- Plastic components (e.g., end caps, guides, handles) are produced through precision injection molding using engineering-grade polymers (e.g., ABS, nylon) chosen for their durability, impact resistance, and smooth operation.

- Metal components for the retraction mechanism (e.g., springs, axles) are manufactured using high-precision CNC machining and stamping processes, ensuring exact tolerances for flawless functionality. Quality control during this stage is paramount, as the smooth retraction of a roller mosquito screen heavily relies on these components.

- Assembly & Integration:

- The cut-to-size aluminum profiles, mesh, and pre-assembled mechanical components are brought to an advanced assembly line.

- Automated and semi-automated workstations are used for precise assembly, including:

- Inserting the spring mechanism and mesh into the cassette housing.

- Attaching side rails with brush seals.

- Integrating the bottom bar and guiding mechanisms.

- For motorized units, integrating the motor and wiring according to electrical safety standards.

- Quality Control & Testing:

- Each `Roller Screen Window` undergoes rigorous multi-stage quality control. This includes:

- Dimensional Accuracy Checks: Ensuring precise measurements against design specifications.

- Operational Smoothness Test: Repeated retraction and extension cycles to ensure fluid motion, proper tension, and soft-close functionality.

- Sealing Integrity Test: Inspection of brush seals and magnetic strips for complete insect barrier.

- Material Integrity Checks: Visual inspection for defects, scratch resistance of coatings, and mesh tension.

- Durability Testing: Random batch testing for extended cycle life (e.g., 10,000+ open/close cycles) and environmental resistance (e.g., simulated rain, UV exposure).

- Each `Roller Screen Window` undergoes rigorous multi-stage quality control. This includes:

Inspection Standards & Certifications: CRScreen adheres to international quality management systems, notably ISO 9001:2015, ensuring consistent product quality from design to delivery. Material specifications often comply with ASTM International standards (e.g., ASTM B221 for aluminum alloys, ASTM D3656 for fiberglass mesh). Our products are designed to meet or exceed relevant building codes and safety standards, providing robust and reliable `anti mosquito window` solutions for a wide array of environments.

Application Scenarios and Technical Advantages

The versatility and discreet design of the roller mosquito screen make it suitable for a vast array of application scenarios, offering significant technical advantages over traditional screening methods.

Typical Application Scenarios:

- Residential Homes & Apartments: Ideal for bedrooms, living rooms, kitchens, and sunrooms where maintaining clear views, maximizing natural light, and providing insect protection are crucial. They blend seamlessly with various window types, including casement, sliding, and tilt-and-turn windows.

- Commercial Establishments: Hotels, restaurants (especially those with outdoor seating or kitchens requiring pest control), offices, and retail spaces benefit from the professional appearance and high functionality of `roll up window screens`.

- Healthcare Facilities: Hospitals and clinics require stringent hygiene standards. An effective `anti mosquito window` solution like the Roller Screen Window prevents insect entry without compromising ventilation, critical for patient comfort and air quality.

- Coastal & High-Humidity Regions: The use of corrosion-resistant aluminum and PVC-coated fiberglass mesh makes these screens highly durable in environments exposed to salt spray and high moisture, common in coastal residential and commercial properties.

- Educational Institutions: Schools and universities utilize them to ensure a comfortable learning environment free from insect distractions.

Technical Advantages of CRScreen Roller Screen Window:

- Energy Efficiency & Enhanced Airflow: By allowing windows to remain open without insect intrusion, the `Roller Screen Window` facilitates natural cross-ventilation, reducing reliance on air conditioning and contributing to energy savings. Its high transparency mesh ensures minimal obstruction to airflow.

- Superior Corrosion Resistance: The powder-coated 6063-T5 aluminum frames offer exceptional resistance to rust and degradation, making them suitable for challenging environments. This is a significant improvement over less robust materials that corrode over time.

- Aesthetic Integration & Space-Saving: The retractable nature means the screen disappears into a discreet housing cassette when not in use. This preserves the architectural aesthetics of the building and allows for unobstructed views, unlike fixed screens that are always visible. It's a key advantage of `roll up window screens`.

- Child and Pet Friendly: Unlike traditional screens that can be pushed out, the taut mesh and secure guides of a quality roller mosquito screen offer a safer barrier. Pet-resistant mesh options further enhance durability against claws.

- UV Protection: The PVC-coated fiberglass mesh filters a significant percentage of harmful UV rays (often over 70%), protecting interior furnishings, flooring, and artwork from fading and damage.

- Ease of Cleaning and Maintenance: When retracted, the mesh is protected within its cassette, reducing dust accumulation. When extended, the smooth surface of the mesh is easy to wipe clean, far simpler than cleaning fixed screens.

- Customization and Versatility: Available in various sizes, frame colors, and mesh types, the `Roller Screen Window` can be customized to fit virtually any window or door opening, aligning with specific architectural and functional requirements.

Manufacturer Comparison & CRScreen's Unique Offerings

When selecting a roller mosquito screen, evaluating manufacturers is crucial. While many companies offer similar products, key differentiators lie in material quality, manufacturing precision, warranty, and customer support. Below is a general comparison highlighting what sets CRScreen apart in the market for `anti mosquito window` solutions.

Roller Mosquito Screen Manufacturer Comparison

| Feature | Premium Brands (e.g., CRScreen) | Mid-Range Brands | Budget Brands |

|---|---|---|---|

| Frame Material | High-grade 6063-T5 aluminum, multi-stage powder coating | Standard aluminum, basic powder coating or painted | Thinner aluminum, possibly steel, simple paint finish |

| Mesh Quality | Premium PVC-coated fiberglass (18x16, 20x20) with high UV resistance; pet/pollen options | Standard PVC-coated fiberglass (18x16) | Basic fiberglass, prone to stretching/tearing, lower UV resistance |

| Retraction Mechanism | Advanced spring system with soft-close; precision-engineered components, optional motorization | Standard spring system, potentially less smooth or noisy | Basic spring, may lack durability or smooth operation |

| Sealing System | Integrated brush seals and magnetic strips for comprehensive barrier | Basic brush seals, potential small gaps | Minimal or poor sealing, allowing insect entry |

| Durability & Lifespan | 10-15+ years; excellent resistance to wear & environment | 5-10 years; adequate for moderate conditions | 2-5 years; susceptible to weather and frequent use |

| Warranty & Support | Comprehensive 5-year+ limited warranty, dedicated customer service, technical support | 1-3 year limited warranty, basic support | Limited or no warranty, minimal support |

| Customization | Extensive options: custom sizes, colors, mesh types, motorized systems | Limited size and color options | Standard sizes only, few options |

| Certifications | ISO 9001:2015, adherence to ASTM, AAMA standards | May have basic material certifications | Few or no recognized certifications |

CRScreen's Differentiating Factors:

- Uncompromising Material Quality: We source only the finest materials, ensuring that every component of our `Roller Screen Window` meets rigorous standards for durability, performance, and environmental resistance.

- Precision Engineering & Manufacturing: Our state-of-the-art facilities and automated processes minimize human error, resulting in consistent, high-quality products with flawless operation. The soft-close mechanism is a testament to our engineering prowess, preventing sudden snaps and enhancing safety.

- Comprehensive Customization: From bespoke sizing to a wide range of frame finishes and specialized mesh types (e.g., pet-resistant, anti-pollen), we offer solutions tailored to unique customer needs, ensuring perfect integration with any architectural style.

- Rigorous Quality Assurance: Every unit undergoes exhaustive testing, far beyond industry minimums, ensuring that our `roll up window screens` not only meet but exceed customer expectations for longevity and reliability.

- Exceptional Customer Service & Warranty: Our commitment extends beyond the sale. We offer robust warranty coverage and dedicated support, providing peace of mind and demonstrating our confidence in product longevity.

Customization Solutions and Seamless Integration

One of the significant advantages of the CRScreen roller mosquito screen is its adaptability. We understand that every project, whether a residential renovation or a large commercial development, has unique requirements. Our customization options ensure that the `Roller Screen Window` seamlessly integrates with your existing architecture and specific functional needs.

Customization Options Include:

- Exact Sizing: Custom-fabricated to the precise dimensions of your window or door openings, ensuring a perfect, gap-free fit and optimal insect protection.

- Frame Colors & Finishes: A wide palette of powder-coated frame colors is available to match or complement your existing window frames, trim, or building facade. This ensures aesthetic harmony for your `anti mosquito window`.

- Mesh Types:

- Standard Fiberglass Mesh: High transparency and durability.

- Pet-Resistant Mesh: Made from thicker polyester yarns, designed to withstand pet claws without tearing.

- Pollen-Blocking Mesh: A finer weave designed to filter out pollen and fine dust particles, ideal for allergy sufferers.

- Solar Screen Mesh: Offers enhanced UV protection and glare reduction while still providing insect barrier.

- Operation Methods:

- Manual Spring-Loaded: Classic, reliable, and cost-effective.

- Motorized Systems: Integrated motors allow for effortless operation via remote control, wall switch, or even smart home automation systems (e.g., integration with Alexa, Google Home via third-party hubs).

- Installation Types: Designed for both inside and outside mount applications, ensuring flexibility for various window types and architectural considerations.

Our expert team works closely with clients, architects, and contractors from the initial consultation to final installation, providing detailed technical drawings and recommendations to ensure the chosen roller mosquito screen solution perfectly aligns with project specifications and aesthetic goals.

Application Cases and Customer Testimonials

The practical application of CRScreen's `Roller Screen Window` speaks volumes about its effectiveness and customer satisfaction. Here are a few illustrative cases:

Case Study 1: Luxury Coastal Villa - Florida, USA

Challenge: A luxury villa overlooking the ocean faced persistent issues with mosquitoes and salt corrosion on traditional fixed screens, compromising views and requiring frequent replacement.

Solution: CRScreen provided custom-sized `Roller Screen Window` units for all large casement and sliding doors. The frames were specially treated with enhanced corrosion-resistant powder coating, and the PVC-coated fiberglass mesh was selected for its durability and high transparency. The retractable nature allowed residents to enjoy unobstructed ocean views when screens were not needed.

Outcome: "The CRScreen roller mosquito screen transformed our home. We can now open our windows to enjoy the sea breeze without worrying about insects, and the screens simply disappear when we want clear views. The quality and finish are exceptional, standing up perfectly to the coastal environment." - Homeowner, Miami, FL

Case Study 2: Boutique Hotel Renovation - Kyoto, Japan

Challenge: A historic hotel undergoing renovation needed `anti mosquito window` solutions that respected its traditional aesthetic while offering modern comfort to guests, without bulky screens.

Solution: CRScreen designed a discreet `roll up window screens` system, with narrow, custom-colored aluminum cassettes that blended seamlessly into the window frames. Manual spring-loaded operation was chosen for its simplicity and reliability, complementing the traditional design.

Outcome: "Our guests highly appreciate the ability to open windows for fresh air without mosquito worries. The roller mosquito screen system is so subtle, it's almost invisible, preserving the classic charm of our rooms. CRScreen's attention to detail was impressive." - Hotel Manager, Kyoto

Case Study 3: Modern Office Building - Singapore

Challenge: A new commercial building aimed for LEED certification, requiring enhanced natural ventilation and occupant comfort, but needed robust insect protection in a tropical climate.

Solution: CRScreen installed motorized `Roller Screen Window` systems in specific office zones, integrated with the building's smart automation system. This allowed for automated retraction and extension based on external weather conditions and indoor air quality, optimizing energy use and comfort.

Outcome: "The integrated roller mosquito screen solution from CRScreen was a key component in our sustainable design. It provides excellent insect control and contributes significantly to our energy efficiency goals, demonstrating advanced `anti mosquito window` technology." - Project Architect, Singapore

Frequently Asked Questions (FAQ) about Roller Mosquito Screens

What are the key materials used in your roller mosquito screen?

Our Roller Screen Window frames are crafted from high-grade 6063-T5 extruded aluminum alloy, known for its strength and corrosion resistance. The mesh is typically a durable, PVC-coated fiberglass, which offers excellent transparency, UV resistance, and fire retardancy. Key internal components for the retraction mechanism are made from precision-engineered plastics and metals ensuring smooth operation and longevity.

How does the `Roller Screen Window` ensure optimal insect protection?

The Roller Screen Window achieves optimal insect protection through a combination of precision engineering and effective sealing. The high-density PVC-coated fiberglass mesh (standard 18x16 or 20x20 count) effectively blocks even tiny insects. Integrated brush seals along the side rails and a magnetic strip or brush seal on the bottom bar ensure a tight, gap-free closure when the screen is deployed, creating an impenetrable barrier against pests for your `anti mosquito window`.

What is the expected lifespan of these `roll up window screens`?

Under normal operating conditions and with proper maintenance, the CRScreen `Roller Screen Window` has an expected lifespan of 10-15 years. This longevity is attributed to the high-quality materials used, such as corrosion-resistant aluminum and UV-stable mesh, as well as our rigorous manufacturing and quality control processes.

Can these screens be installed on all types of windows?

Our roller mosquito screen systems are highly versatile and can be custom-fitted to most window types, including casement, sliding, tilt-and-turn, and fixed windows. They are designed for both internal and external mounting, providing flexibility for diverse architectural styles and window designs. We offer comprehensive measurement guides and professional consultation to ensure a perfect fit.

What maintenance is required for a `roller mosquito screen`?

Maintenance for our `Roller Screen Window` is minimal. Periodically, the mesh can be wiped down with a soft cloth and mild soapy water to remove dust and debris. The aluminum frame can be cleaned with a damp cloth. It's advisable to keep the guide rails free of obstructions to ensure smooth operation. Avoid harsh chemicals or abrasive cleaning tools to preserve the finish and mesh integrity.

Are there options for pet-resistant mesh or pollen-filtering mesh?

Yes, we offer specialized mesh options to cater to specific needs. Our pet-resistant mesh is made from a thicker, more durable polyester material, designed to withstand scratching from pets. We also provide a finer-weave pollen-filtering mesh, which is highly effective in blocking airborne allergens while still allowing for excellent airflow, enhancing the functionality of your `anti mosquito window` solution.

What are the warranty and after-sales support terms?

CRScreen provides a comprehensive 5-year limited warranty on the Roller Screen Window, covering defects in materials and workmanship under normal use. Our dedicated customer support team is available to assist with any queries regarding installation, maintenance, or troubleshooting, ensuring long-term satisfaction with your roller mosquito screen.

Delivery Cycle, Quality Assurance, and Customer Support

At CRScreen, we are committed to not only delivering high-quality roller mosquito screen solutions but also ensuring a seamless customer experience from order to installation and beyond.

Delivery Cycle:

Our standard production and delivery cycle for custom `Roller Screen Window` orders typically ranges from 2 to 4 weeks, depending on the complexity of customization and order volume. For large commercial projects or highly specialized requirements, lead times will be communicated clearly during the quoting process. We prioritize efficient logistics and work with trusted shipping partners to ensure timely and secure delivery of your `anti mosquito window` solutions to your location, whether domestic or international.

Quality Assurance Commitment:

Our commitment to quality is unwavering. Every `Roller Screen Window` produced by CRScreen undergoes a multi-point inspection process, adhering strictly to our ISO 9001:2015 certified quality management system. From raw material inspection to final product testing, each stage is meticulously monitored to ensure:

- Dimensional Precision: Exact adherence to custom measurements.

- Operational Flawlessness: Smooth and quiet retraction/extension cycles, consistent spring tension, and secure locking mechanisms.

- Material Integrity: Verification of frame coating durability, mesh tensile strength, and UV resistance.

- Sealing Effectiveness: Ensuring no gaps for insect ingress.

Customer Support:

Our relationship with clients extends far beyond the point of sale. CRScreen offers comprehensive customer support, including:

- Pre-Sales Consultation: Expert advice on product selection, measurement, and customization to match your specific needs for `roll up window screens`.

- Technical Assistance: Guidance for professional installation, troubleshooting, and maintenance.

- After-Sales Service: Prompt response to any warranty claims or service inquiries.

Conclusion: Redefining Comfort and Protection

The CRScreen roller mosquito screen represents the pinnacle of modern insect protection technology. By seamlessly blending aesthetic elegance with robust functionality, it addresses the evolving demands of contemporary living. Its advanced technical specifications, precise manufacturing process, and versatile application scenarios underscore its superiority as an `anti mosquito window` solution. From enhancing energy efficiency and providing unparalleled insect control to offering comprehensive customization and long-term durability, the `Roller Screen Window` is an investment in comfort, health, and property value.

We invite you to explore the full potential of our Roller Screen Window and transform your living or working spaces. Visit our product page at https://www.crscreen.com/roller-screen-window.html to learn more and request a consultation for your specific needs. Experience the difference that a truly advanced `roll up window screens` solution can make.

References and Further Reading

-

Building Science & Comfort: Insights into natural ventilation and indoor air quality.

https://www.buildingscience.com/documents/insights/bsi-091-all-about-air-barriers -

Advanced Materials in Construction: Discussion on modern aluminum alloys and composite materials for building envelopes.

https://www.sciencedirect.com/journal/construction-and-building-materials -

Vector Control & Public Health: Research on effective physical barriers against disease-carrying insects.

https://www.who.int/publications/i/item/9789241508920 -

Smart Home Technology Integration: Trends in automated window solutions and building management systems.

https://www.smarthome.com/articles/smart-home-integration-101

This is the first article

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025