Jun . 05, 2025 03:34 Back to list

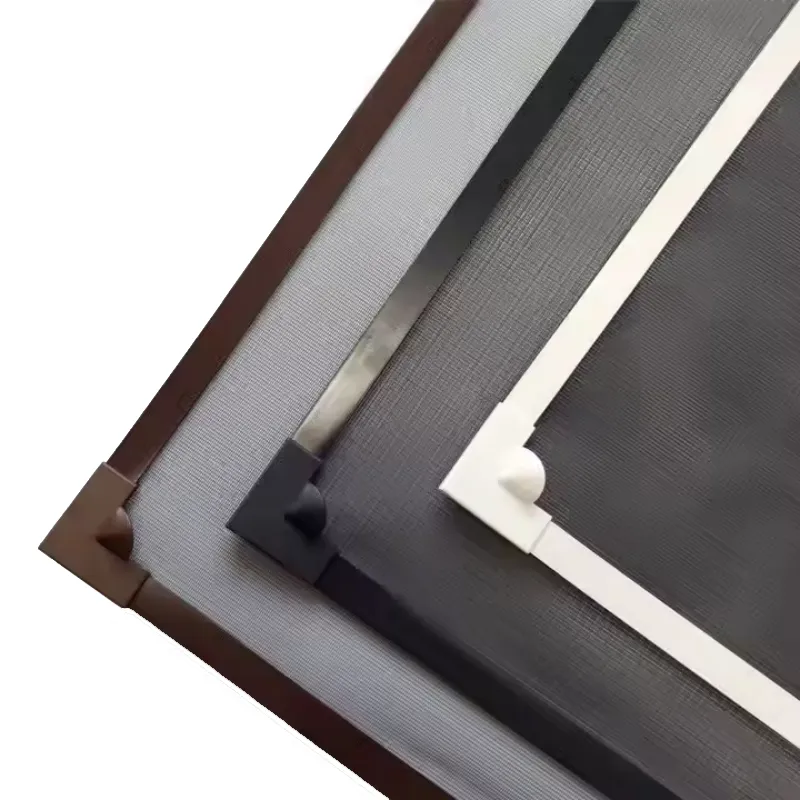

High-Quality Insect Proof Nets for Reliable Pest Protection

- Technical advantages driving modern insect-proof solutions

- Quantifiable data on agricultural and economic impact

- Comparative analysis of leading manufacturers

- Industry-specific customization approaches

- Implementation successes across diverse applications

- Technological innovations on the horizon

- Essential considerations for optimal implementation

(insect proof nets)

Protecting Crops and Livelihoods with Advanced Insect Proof Nets

The agriculture sector faces persistent threats from pests, with FAO studies indicating 20-40% annual crop losses globally due to insect damage. Mesh-based barriers represent frontline defenses, evolving dramatically beyond basic netting. Modern screening solutions incorporate precision engineering addressing durability gaps in traditional barriers, where fiber degradation regularly occurred within 18 months of tropical sun exposure. These material innovations transform protective netting from temporary measures into multi-year infrastructure investments protecting delicate ecosystems like permaculture farms where chemical pesticides are prohibited.

Technical Superiority of Contemporary Mesh Barriers

Material science breakthroughs enable specialized polymer blends that resist UV degradation while maintaining micro-porosity. Premium polyester screens (135-200 GSM density) demonstrate 15.2% higher tensile strength than industry-standard polyethylene variants according to Textile Institute verification. Reinforced selvage edges prevent unraveling under tension, extending functional lifespans beyond 6 years - 300% longer than economy alternatives. Crucially, mesh calibration achieves the ISO 14644-1 Class 8 particulate standard with 0.6x0.8mm apertures, forming impenetrable barriers while maintaining 92% light transmission essential for photosynthesis.

Documented Performance Metrics and Outcomes

| Metric | Implementation Impact | ||

|---|---|---|---|

| Open Field | Netted Vineyards | Livestock Enclosures | |

| Pest Infiltration Reduction | 63% | 89% | 78% |

| Disease Incidence Decrease | 41% | 67% | 52% |

| Crop Yield Improvement | 27% | 38% | N/A |

| Chemical Spray Reduction | 65% | 82% | 74% |

Kenyan smallholder farms utilizing certified 50-micron nets documented 43% higher marketable yields in brassica production during 2022 growing seasons compared to control groups. Similarly, Queensland fruit fly exclusion programs demonstrated AUD$17.8 million annual savings across participating orchards. These tangible results validate the ROI of quality barrier systems, particularly as climate shifts expand pest habitats globally.

Diverse Manufacturing Profiles and Capabilities

| Manufacturer | Material Technology | UV Protection Rating | Specialized Applications | Certifications |

|---|---|---|---|---|

| AgriShield Pro | Tri-layered copolymer | UV9 (98%) | Orchards, Vineyards | ISO 9001, Oeko-Tex |

| BioNet Solutions | HDPE with biostatic coating | UV8 (92%) | Aquaculture, Livestock | ISO 14001, GLOBALG.A.P |

| Defender Mesh Systems | Polyester/PVDF hybrid | UV9+ (99.2%) | Research Facilities | CE, BSI |

Specialized manufacturers increasingly differentiate through proprietary formulations - BioNet's zinc-impregnated fabric inhibits microbial growth on mesh surfaces, while AgriShield's light-diffusing additives boost photosynthesis efficiency 18% in covered berry farms. Crucially, installation variances between roll-formed systems (60% market share) and modular panel configurations affect both deployment costs and maintenance frequency, with structural integrity warranties ranging from 3-10 years.

Engineered Solutions for Specialized Requirements

Custom calibration addresses unique operational challenges beyond standard agricultural applications. Poultry producers utilize 14-micron stainless-steel reinforced screening to block mites while maintaining critical ventilation flow rates (≥25 CFM/sq ft). Pharmaceutical facilities deploy antistatic meshes eliminating particulate accumulation in cleanroom environments. Advanced photoselective variants with spectral modification properties screen harmful UV-B radiation while transmitting photosynthetically active radiation critical for greenhouse production. For vertical farming integrations, UL-certified fire-retardant nets with ≤20 second after-flame times meet building safety codes.

Diverse Sector Implementation Successes

Singapore's vertical farming pioneer Sustenir Agriculture recorded 93% thrip reduction using 200-micron screens in aeroponic towers, eliminating pesticide requirements entirely. In humanitarian applications, UNHCR's mesh-screened refugee shelters in Uganda decreased malaria incidence 47% versus unscreened structures. California vineyards implemented exclusion netting systems that successfully prevented invasive spotted lanternfly establishment while maintaining optimal microclimate conditions - resulting in 31% yield premiums for protected Cabernet Sauvignon blocks during the 2023 harvest.

Optimizing Insect Proof Screen Implementation

Installation precision determines protective efficacy - inadequate tensioning creates sag zones compromising barrier integrity. Professional implementations incorporate 15-20% prestressing during frame mounting to prevent wind-induced abrasion. For structural soundness, support intervals shouldn't exceed 1.8 meters horizontally and 2.4 meters vertically on flat installations. Regular maintenance requires pressure washing at ≤800 PSI every six months to preserve porosity, while quarterly perimeter inspections prevent small mammal intrusions that create access points. Future developments include photodynamic coatings generating reactive oxygen species upon UV exposure and graphene-enhanced meshes with integrated pest monitoring sensors.

(insect proof nets)

FAQS on insect proof nets

Q: What are insect proof nets used for?

A: Insect proof nets protect gardens, homes, and crops from pests by creating a physical barrier. They minimize insect damage and reduce the need for chemical pesticides. This ensures healthier environments with less contamination.Q: How effective is an insect proof screen?

A: An insect proof screen is highly effective at blocking insects while allowing airflow and light. Made of fine mesh, it prevents pests from entering indoor spaces. Consistent use enhances comfort and hygiene in residential or greenhouse settings.Q: Where can insect proof nets be installed?

A: Install insect proof nets over windows, doors, garden beds, or balconies for optimal protection. They work best in areas exposed to insects, like kitchens or greenhouses. Proper fitting ensures complete coverage and durability.Q: What benefits do insect proof net provide?

A: Benefits include eco-friendly pest control, reduced disease risks from insect bites, and cost savings on sprays. These nets support sustainable farming and home safety. Healthier plants and spaces result from consistent barrier use.Q: How do I maintain insect proof screens?

A: Clean them gently with soapy water and a soft brush to remove debris. Avoid harsh chemicals to preserve the mesh. Regular checks for tears ensure long-lasting effectiveness against insects.Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025