Ogo . 05, 2025 11:00 Back to list

Magnetic Window Net - Easy Install, Bug-Free Ventilation

The increase in demand for comfortable, insect-free, and well-ventilated interiors has propelled innovations in window screening technology. Among the pioneers is the magnetic window net system, also known as magnetic window mesh or magnetic screen window. This article offers a comprehensive exploration of these products — delving into production processes, technical parameters, industry trends, and real-world experiences, supported by authoritative data and professional comparisons.

1. Industry Trends: Magnetic Window Net in a Rapidly Growing Market

Driven by urbanization, smart home adoption, and stricter building codes, the global window screen market is expected to surpass $2.8 billion by 2027 (MarketsandMarkets Report). Magnetic window net solutions are experiencing a CAGR of 8-10% globally — notably in Southeast Asia, Europe, and North America — due to their tool-free installation, robust sealing performance, and eco-friendly materials.

- Key Applications: Residential homes, hotels, hospitals, clean-rooms, petrochemical facilities, metallurgical plants, and sewage processing units.

- User Priorities: Energy-saving (up to 20% better insulation), anti-corrosion, easy maintenance, ISO/FDA compliant materials.

Fact: According to the Window & Façade Asia Association, magnetic screen mesh reduces annual maintenance costs by 30% versus traditional frames.

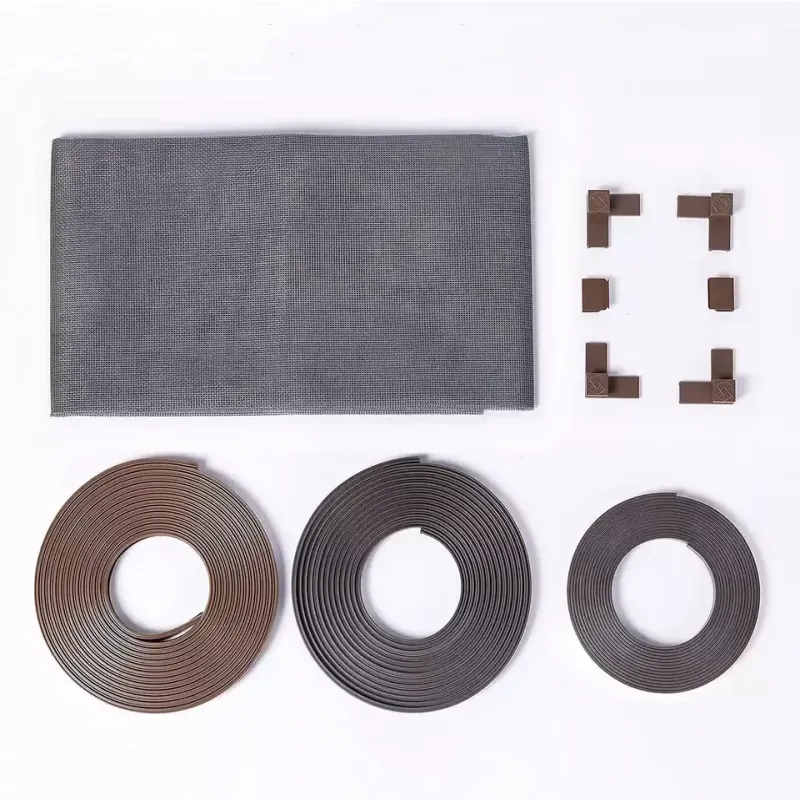

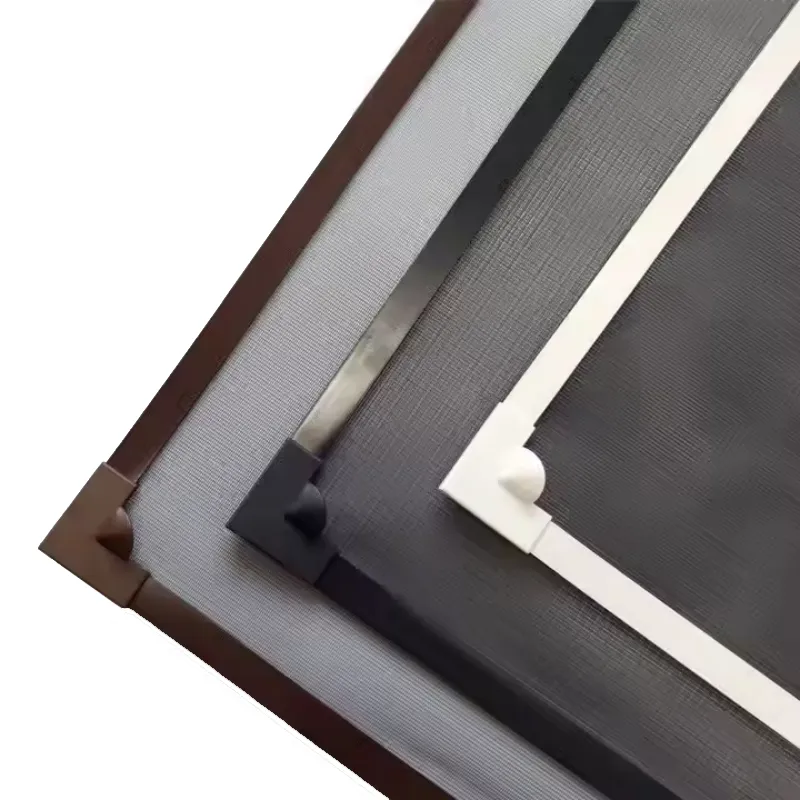

2. Technical Parameters & Materials: What Makes a Premium Magnetic Screen Window?

A magnetic window net is engineered for robust performance and longevity, requiring attention to details at every production step. Top manufacturers use advanced materials, strict quality controls (ISO 9001, ANSI/BHMA), and precision assembly methods.

| Parameter | Magnetic Window Net | Traditional Fiberglass Screen | Retractable Screen |

|---|---|---|---|

| Material | Nano-PP mesh / Stainless Steel 304 & 316L / Polyester Mesh + Rare-Earth Magnetic Strips | Glass Fiber Mesh / Aluminum Alloy Frame | Polyester / PVC Mesh + Metal Spring Cassette |

| Mesh Aperture | 1.0–1.5mm | 1.2–1.8mm | 1.0–1.5mm |

| UV Resistance | Up to 98% | 60-80% | 80-90% |

| Magnetic Force | 37–45mT (strong closure) | None | None |

| Corrosion Resistance | Excellent (≥2000 hrs Salt Spray Test) | Average | Good |

| Installation | Tool-free, Snap-in & Detachable | Screw/Clamp Fixed | Screw/Fitted Channel |

| Service Life | ≥12 years | 3–7 years | 5–8 years |

| Certifications | ISO 9001:2015, ROHS, SGS Tested | ISO 9001 | ISO 9001 |

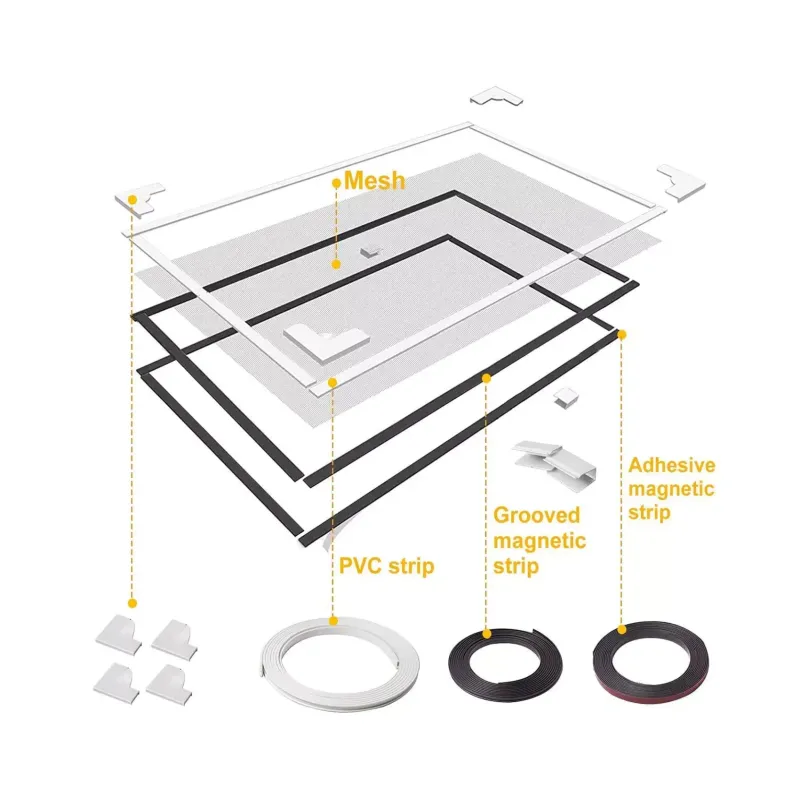

3. Manufacturing Process: From Raw Material to Magnetic Screen Window

The performance of a magnetic window net is a direct reflection of its manufacturing process. Below is a graphical summary:

- A. Mesh Weaving: High-precision PP/stainless mesh woven on CNC looms.

- B. Magnetic Strip Injection: Rare-earth (NdFeB) magnets encased in flexible silicone/TPU strips.

- C. Frame CNC Cutting: Aluminum/ABS frames precision-cut for perfect fit & sealing.

- D. Assembly & Bonding: Mesh and magnet strips are bonded under high-temperature presses.

- E. QC Inspection: Salt spray, pull strength, UV and fire resistance (UL 723/ISO 4892).

- F. Packaging/Shipped: Final sanitation, shrink packaging, QC tag, shipped globally.

4. In-Depth Product Comparison: Magnetic Window Net vs. Competitors

| Brand | Key Market | Main Mesh Material | Magnet Type | Frame Material | Installation Mode | ISO/ROHS Certified | Warranty |

|---|---|---|---|---|---|---|---|

| CR SCREEN | Global/Industrial | 304/316L Stainless, Nano-PP, Antibacterial Mesh | NdFeB, Silicone Multi-seal | Aluminum Alloy (Al6063-T5), ABS | Tool-free, Snap-on | ✓ | 3–5 yrs |

| Phifer | USA/Residential | Fiberglass/Polyester | Ferrite, Single-seal | PVC Coated Aluminum | Velcro/Magnetic Strip | ✓ | 2 yrs |

| Flyscreen Co | SEA, Europe | HDPE | Ferrite | PVC | Channel Fixed | Partial | 1 yr |

| OEM Brands | China, India | Polyester/Nylon | Generic Strip | ABS | Adhesive | Varies | 6–12 mo |

5. Technical Data Visualization: Magnetic Screen Window Performance

6. Customization & Engineering Services

Magnetic window mesh products are increasingly tailored for multi-industry demands. CR SCREEN delivers solutions for:

- Petrochemical facilities: Anti-explosion mesh (316L grade), corrosion-proof, up to 3000hr salt spray.

- Metallurgy & Mining: Heat-stable mesh up to 170℃, reinforced NR magnets.

- Sewage & Waterworks: Mould-proof, antibacterial mesh with FDA food-grade certificates.

- Medical/Healthcare: Laser-welded, anti-microbial mesh for sterile air barriers.

- Smart Home Integration: IoT-compatible seals, fingerprint-openable frames (on request).

Customization Parameters:

- Size: 300x300mm to 2600x2100mm (single unit)

- Mesh Aperture: 0.8mm–2.0mm

- Frame: Color anodized, powder-coated, ABS composite

- Magnet: Multi-point, continuous seal, or 4-side snap-in

7. Application Cases & Customer Experience

Industry experience demonstrates the value of advanced magnetic window net products:

- Kuala Lumpur General Hospital, Malaysia: Replaced fixed screens with 4500+ magnetic screen windows, improving ventilation and nurse maintenance access. Annual pest ingress incidents dropped by 84%.

- Sinopec Petrochemical, Tianjin: Deployed flame-retardant, anti-static mesh in hazardous zones, certified to UL 94-V0; achieved zero corrosion claims over 3 years.

- BASF R&D, Ludwigshafen: Installed smart magnetic mesh with RFID security triggers for lab airlocks.

- Plaza Residences, Singapore: Magnetic mesh systems cut aircon energy bills by 19%; user feedback highlighted seamless appearance and easy cleaning.

8. International Standards & Quality Assurance

CR SCREEN Magnetic Window Nets adhere to the following international standards and certifications, ensuring industry-leading performance:

- ISO 9001:2015 Quality Management

- ROHS/REACH (EU Heavy Metal Directive)

- SGS Weather/Humidity/UV Testing

- ANSI A2096 (USA domestic window mesh test)

- FDA 21CFR177.1520 (for water and medical applications)

Certifications and test reports are available on request.

9. Delivery, Warranty, and After-Sales Support

- Production & Delivery: Lead time 5-8 working days for custom batches (up to 500 units), 2–3 weeks for industrial projects; air/sea delivery at customer direction.

- Quality Warranty: 3–5 years (structural and corrosion resistance), with free technical support and remote troubleshooting.

- Technical Support: Installation guides, video call support, on-site (APAC/EU), parts supply within 72 hrs globally.

- Return Policy: 30-day replacement or full refund for manufacturing defects.

10. Frequently Asked Questions (FAQ) for Magnetic Window Net Technology

11. Conclusion: Choosing the Right Magnetic Window Net for Your Application

Magnetic window net technology is rapidly setting the standard for modern window screening worldwide — offering superior sealing, insulation, and user experience for home and industry alike. Choose manufacturers with international testing credentials, demonstrated industry experience, and robust after-sales policies to maximize return on investment.

For the latest technical whitepapers, market analysis, and independent reviews, consult reputable sources such as:

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025