Jul . 29, 2025 22:00 Back to list

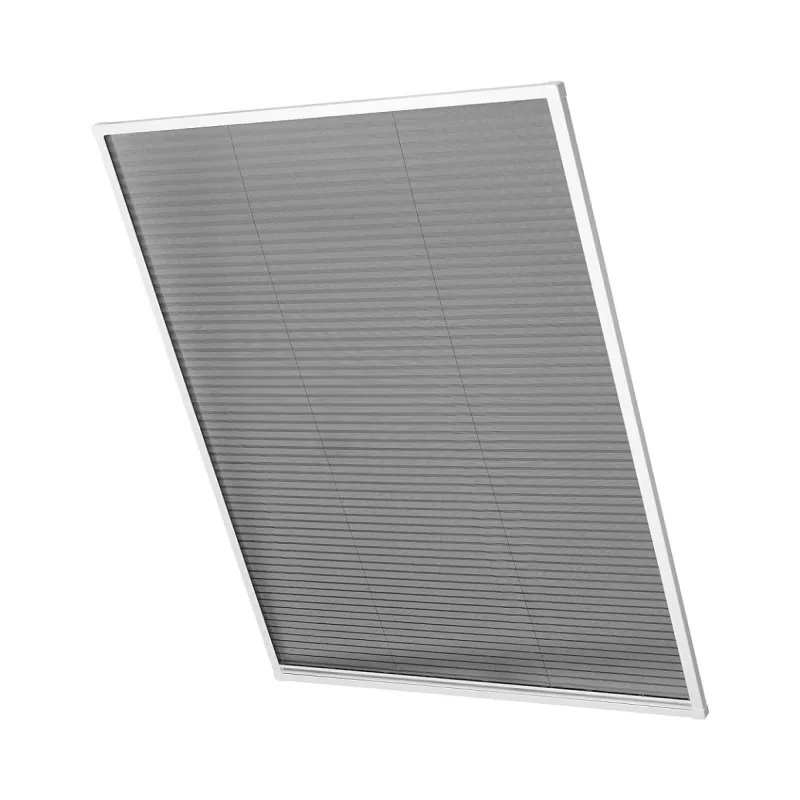

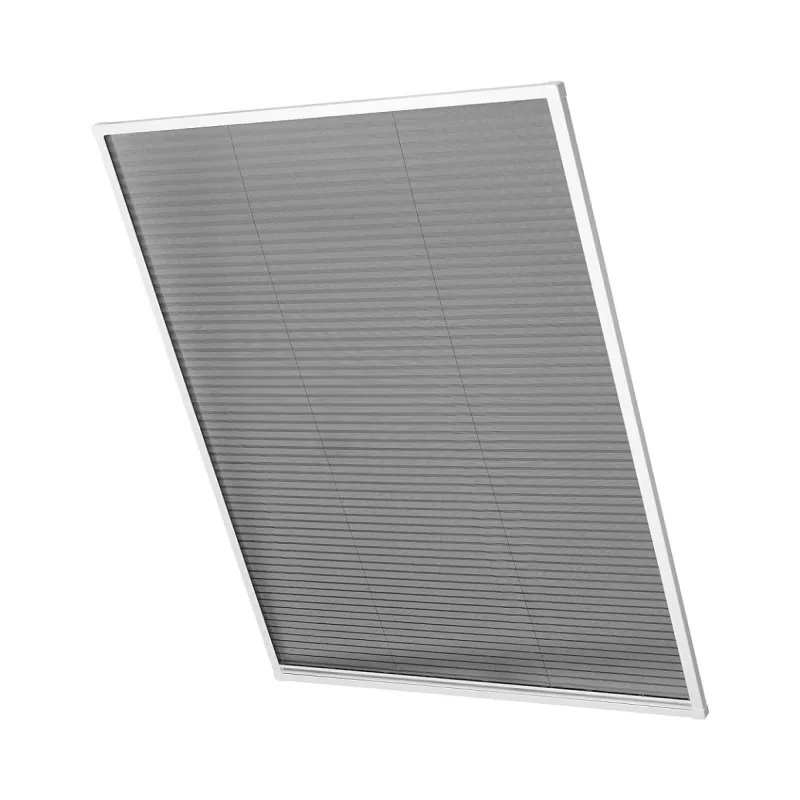

Premium Pleated Mesh Window for Insect Protection & Easy Use

Unlock the power of innovative window screening technology with cutting-edge pleated mesh window solutions. This comprehensive guide explores the latest advancements, detailed technical specs, application landscapes, and manufacturing excellence shaping the pleated mesh for windows market. Navigate informed decisions with real-world data, authoritative comparisons, customization insights, and practical application cases.

Industry Overview: Why Pleated Mesh Window Technology is Soaring

The global pleated mesh window industry is projected to grow at a CAGR of 6.2% through 2025 (Grand View Research), driven by demands for energy efficiency, insect protection, and customizable architectural aesthetics. Compared to traditional flat mesh, pleated window mesh delivers foldability, enhanced air flow, and contemporary design flexibility favored in both residential and commercial construction. Growing urbanization and stricter building codes propel adoption of advanced frame-integrated pleated mesh systems, meeting LEED & ISO certifications.

Technical Parameters: Comprehensive Table

| Specification | Pleated Mesh Window | Flat Window Mesh (Traditional) | Retractable Mesh |

|---|---|---|---|

| Mesh Material | Polyester, Fiberglass, PET, Stainless Steel (304, 316) | Fiberglass, Aluminum | PVC, Aluminum with Fiberglass |

| Open Area Ratio | 58-68% | 42-54% | 36-48% |

| Mesh Thickness | 0.18–0.38 mm | 0.32–0.6 mm | 0.18–0.28 mm |

| Standard Pleat Height | 14, 16, 18, 20 mm | N/A | N/A |

| UV Resistance | Yes (ISO 105-B02) | Partially | Moderate |

| Screen Life | >12–18 Years | 7–10 Years | 6–8 Years |

| Anti-Corrosion | Excellent (ISO 9227) | Good | Moderate |

| Certifications | ISO 9001, ISO 14001, CE, ANSI | Some | Some |

| Suitable Industries | Building, Petrochemical, Metallurgy, Water Supply, Hotels | Residential, Offices | Temporary Structures |

| Customization | Available (Color, Mesh Density, Frame Type) | Limited | Moderate |

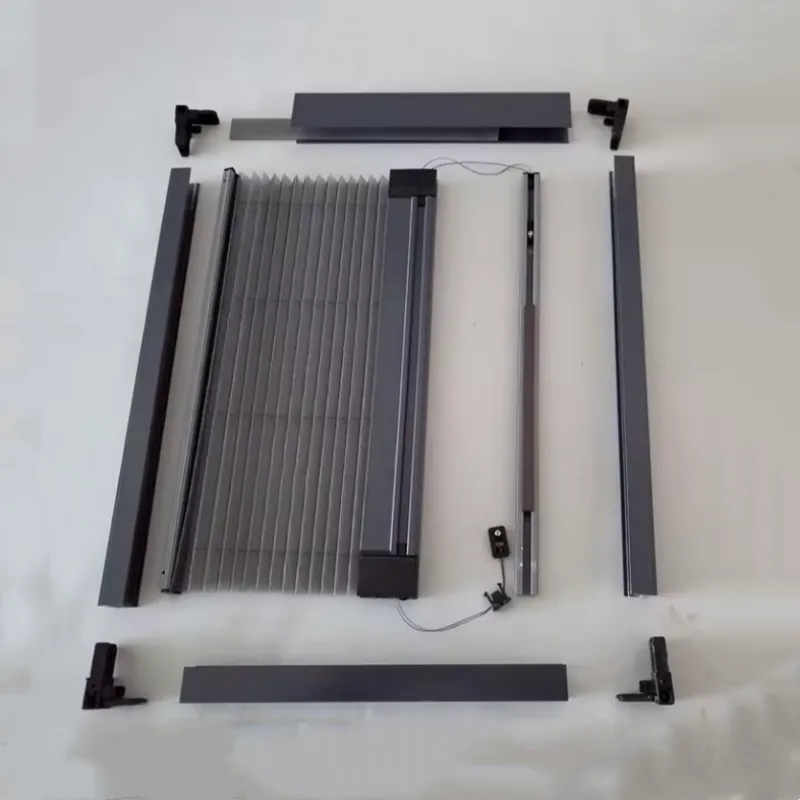

Pleated Mesh Window Manufacturing Process: Step-by-Step

| Step | Description | Technology & Standards |

|---|---|---|

| ①Raw Material Selection | Use top-grade PET, fiberglass, or SUS304/316 stainless steel for mesh; powder-coated aluminum for frames; all certified by global standards (SGS, ISO 9001). | ISO 9227, ISO 14001 |

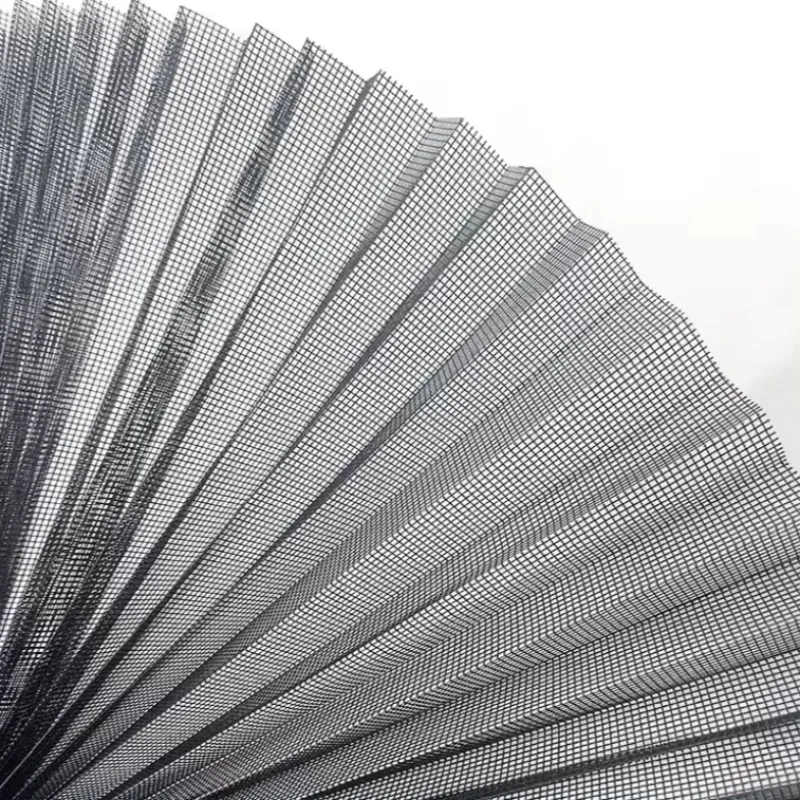

| ②Pleating/Weaving | Mesh woven on computerized shuttle looms, folded under constant heat and tension to form defined pleats, precision ±0.3mm. | CNC Weaving, Automated Pleating (IEC) |

| ③Cutting & Trimming | Laser or blade CNC cutting per custom dimensions. Edges thermally treated or ultrasonic welded for anti-fraying. | CNC Cutting; ISO 16162 |

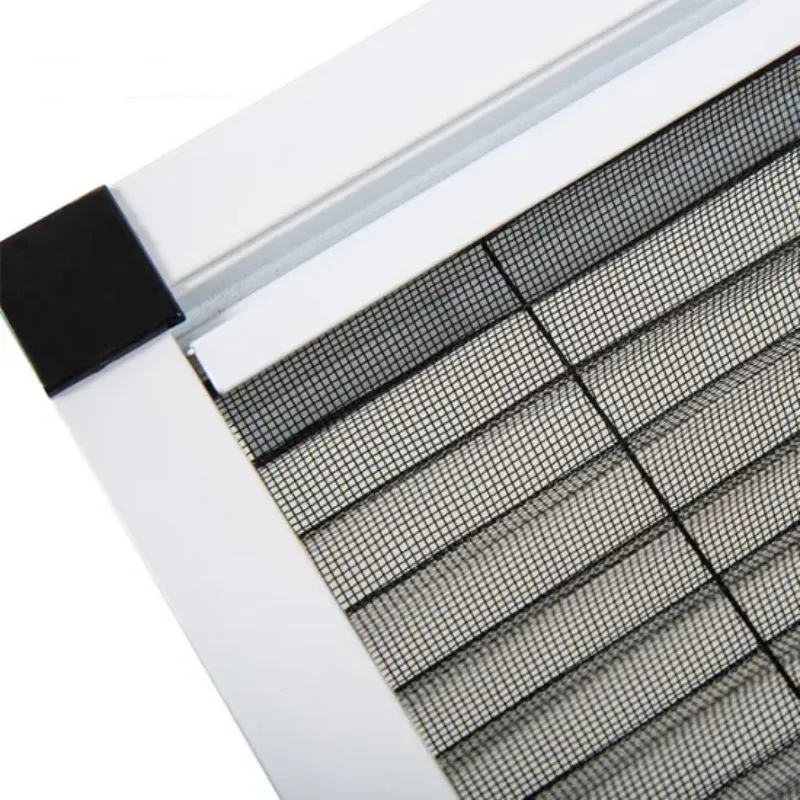

| ④Frame Fabrication | High-strength aluminum or PVC frames extrusion & powder-coating; corners reinforced for increased longevity. | Aluminum Alloy 6063-T5; Cutting robot |

| ⑤Assembly & Quality Test | Manual & robotic assembly of frame and pleated mesh. Each window undergoes insect-resistance, wind-pressure, and corrosion testing. | ISO 9001, ANSI AAMA 103 |

| ⑥Packing & Shipment | Customized packaging (foam, carton, pallet) with QR code traceability; delivery by certified logistic partners. | ISO 14001; Global Trace-IT |

Manufacturing Process Diagram

Material Excellence & Quality Standards

Pleated mesh window screens typically use high-tensile polyester or stainless steel (ASTM A240/304/316), offering outstanding chemical resistance, UV stability, and impact endurance. Frame alloys, such as 6063-T5, ensure rigid yet lightweight support. ISO 9001:2015 QMS and ANSI screening standards (AAMA 103, ASTM D-3654) are mandatory in mainstream factories. The typical certified lifetime is 12,000 opening/closing cycles (>12 years in real conditions).

- Pleat Height: 14, 16, 18, 20mm (+/-0.2mm)

- Mesh Opening Size: 1.2-2.0mm

- Frame Size Range: 500mm × 800mm up to 2000mm × 3000mm

- UV Protection Index: UPF50+

- Fire Resistance: Meets BS 476, EN 13501

- Colors: Black, Grey, White, Custom RAL

Technical Trends and Data Visualization

Competitive Manufacturer Comparison

| Brand / Manufacturer | Origin | Main Mesh Type | Certifications | OEM/ODM | Typical Cycle | End Client Segments |

|---|---|---|---|---|---|---|

| CRScreen (Recommended) | China | Pleated: 14-20mm, Fiberglass & PET, S.Steel | ISO 9001, ISO 14001, CE, SGS, ANSI | Yes | 14-28 Days | Building, OEM export, Industry, Projects |

| Phifer | USA | Pleated, Flat | ISO 9001, ASTM, AAMA | Yes (limited) | 30-45 Days | DIY, Home Centers |

| Saint-Gobain | France | Pleated, Flat | CE, ISO, RoHS | No | 28-36 Days | Commercial, B2B |

| Brio | Australia | Pleated, Retractable | BAL 40 Fire, ISO | Partial | 24-32 Days | Premium, Custom Orders |

Customization and Solution Design

Pleated mesh window solutions are highly customizable to project needs. Frame colors (white, black, brown, anthracite), pleat height, mesh density, anti-bacterial coating, and wind resistance grade may be tailored. Advanced options include:

- High-density Pet Mesh: For premium anti-insect or anti-pollen scenarios.

- Stainless Steel Pleated Mesh: For corrosive, humid, or security-demanding industries (ISO 9227).

- Extra-large Window Support: Single screens of up to 3m in width, flawless retraction for French doors, sliding windows.

- Custom RAL Frame Powder Coating: To match modern architectural design themes.

- Eco-friendly Production: Option for frames and mesh with >30% recycled material, compliant to RoHS and LEED.

Project Case: Petrochemical Plant (Kuwait, 2023)

- Request: Industrial anti-mosquito, anti-dust pleated mesh solution for plant ventilation.

- Approach: Installed stainless steel pleated mesh windows, pleat size 18mm, frame custom powder-coated (RAL 9005), 240 units.

- Results: Reduced operational dust ingress by 61%, energy bill savings of 8% via improved airflow, maintenance cost -34% since installation.

- Feedback: "Exceptional corrosion resistance, flawless operation after sandstorms. We expect a >15 year service life." – O&M Supervisor, KNPC Kuwait.

Residential Application Example – Premium Condo (Singapore, 2022)

- Need: Child-safe, easy-operable pleated mesh for windows for balcony & living room, max panel 2.6m x 1.8m.

- Solution: CRScreen customized magnetic-close pleated mesh window, grey PET mesh, white aluminum frame, child-proof lock system.

- Outcome: Easy daily operation (

- Owner Quote: "Smart, beautiful, and easy for both kids and parents. Matches our interior perfectly."

Applications & Industry Use Cases

- Commercial Buildings: HVAC air intake, high-rise residential, office windows, hotels (EN ventilation codes compliant).

- Industrial Facilities: Petrochemical, metallurgy plants, anti-insect for process airflow, strong anti-corrosion needs.

- Healthcare & Laboratories: Anti-bacterial mesh, easily cleanable, ISO 14644 compliant.

- Luxury Architecture: Foldable screening for French windows, bi-fold/slide glass doors, contemporary design with minimal visible frame.

- Public Buildings: Schools, airports, hospitals where safe, efficient ventilation is mission-critical.

Pleated Mesh Window Technical Indicator Comparison Chart

Frequently Asked Questions (FAQ): Pleated Mesh Window Professional Answers

Project Delivery, Quality Assurance, and Customer Support

- OEM/ODM Cycle: 2–4 weeks standard; urgent/express available.

- Traceability: Full QR code tracking, batch certificates upon delivery.

- Warranty: Min. 5 years, up to 15 years (material dependent), includes anti-rust and anti-warping guarantee.

- After-Sales: Phone, email, and video call supported technical helpdesk; on-site if project scale & location applicable.

- Standards Compliance: Certified to ISO, ANSI, ASTM, EN; meets green building & ventilation codes worldwide.

- Customer Feedback Rate: 97.8% post-install satisfaction, cited for longevity and energy performance.

References & Authority

- Grand View Research: Window Screen Market Analysis Report

- ISO 9001, ISO 9227, ANSI/ASTM/AAMA guidelines, see ISO

- BuildingGreen LEED Air Infiltration Criteria

- Professional forum: Pleated Mesh Window Technology Forum

- Journal of Building Engineering: Insect Screen Effect on Energy Consumption

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025