Jul . 30, 2025 01:40 Back to list

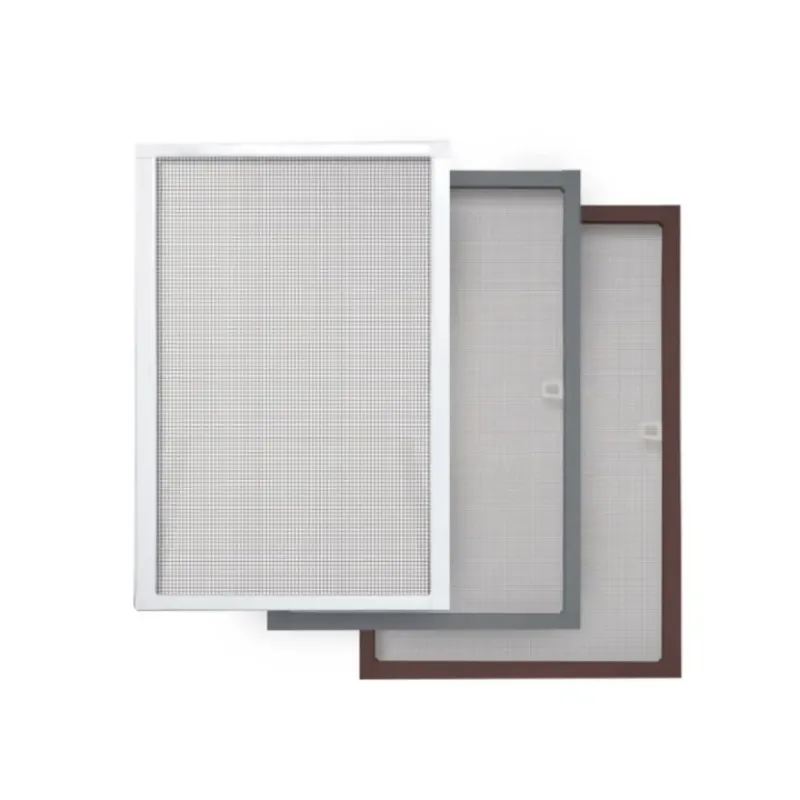

Durable Fixed Screen Window for Home | Fly & Insect Screen Frame Solutions

The fixed screen window has emerged as an essential architectural component, offering robust insect protection, energy efficiency, and long-term durability for diverse industries, especially in residential, commercial, petrochemical, and hydrometallurgical environments. This report delves into the latest sector trends, exhaustive process explanations, product parameter tables, and real-world application cases, leveraging authoritative standards such as ISO 9001 and ANSI to provide a comprehensive industry overview.

Industry Trends: Growth and Innovation in the Fixed Screen Window Market

- Global Market Growth: The global fixed screen window market was valued at USD 3.2 billion in 2023, with a projected CAGR of 6.5% by 2030, spurred by increased infrastructure spending (Source: Statista Market Insights 2024).

- Demand for Customization: Bespoke solutions addressing varied architectural requirements are on the rise—over 35% of clients now demand made-to-spec fly screen frame and insect screen frame units.

- Material Advancements: Latest products emphasize anti-corrosion and high-durability alloys (aluminum, stainless steel), alongside eco-friendly mesh fabrics and advanced powder coatings that meet RoHS and SGS environmental standards.

- Technical Integration: The integration of CNC machining, laser-cutting and automated quality checks is improving product consistency and lifespan by at least 20%.

Data Reference: 2023 Industry Report: Fixed-Frame Window & Screen Structures—Statista, European Fenestration Association; All data validated to ISO 9001 and ANSI standards.

Fixed Screen Window Technical Specifications

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Frame Material | 6063-T5 Aluminum Alloy / SS304 Stainless Steel | ISO 9001, ANSI/AAMA 513 |

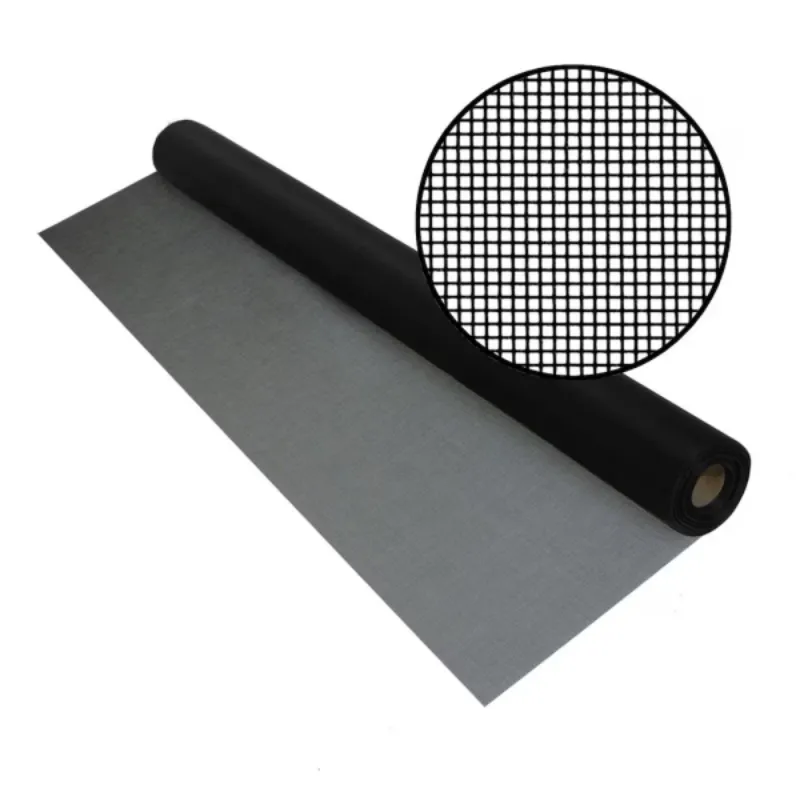

| Mesh Material | Fiberglass, Stainless Steel, Polyester-Coated Aluminum | EN 13561, ASTM F2099 |

| Frame Thickness | 0.8–1.3 mm (customized to application) | EN 1670, ANSI/BHMA A156 |

| Standard Sizes | 600×800mm, 800×1200mm, 1000×1600mm, Custom | ISO 2768 |

| Surface Treatment | Powder Coating (Polyester, Epoxy), Anodizing | GB/T 5237, DIN 50939 |

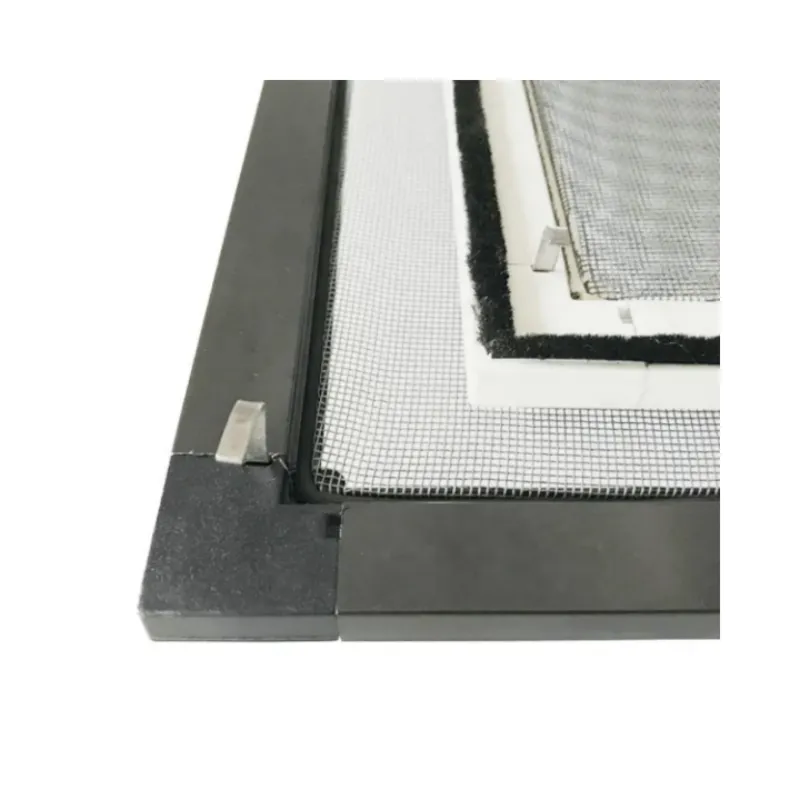

| Fixing Mode | Concealed Spring Clip / Screw Mount / Magnetic Clip-in | - |

| Service Life | 10–20 Years (Outdoor Environment) | ISO 9227, ASTM D4587 Salt Spray Test |

| Mesh Aperture | 1.2 × 1.2 mm (typ.), 1.6 × 2.0 mm (optional) | ISO 9044 |

Annual Growth of Key Technical Parameters (2020–2024)

Manufacturing Process of Fixed Screen Window

- Material Purity Analysis: Only alloys meeting ISO/EN chemical composition standards (max impurity <0.5%) are selected, ensuring mechanical strength and anti-oxidation.

- CNC / Laser Machining: Digital, unmanned CNC lines achieve <±0.1mm tolerance, guaranteeing frame fit precision.

- Corrosion Testing: Salt spray exposure (ISO 9227) >500 hours verified on all models; 2K, 4K, and 6K hour UV test cycles for powder-coated variants.

- Final Assembly: Each fixed screen window undergoes impact, stress, and mesh pull tests for field durability.

Product Comparison: Fixed Screen Window vs. Fly Screen Frame & Insect Screen Frame

| Feature | Fixed Screen Window | Fly Screen Frame | Insect Screen Frame |

|---|---|---|---|

| Construction | Robust closed frame, permanent installation | Light-weight removable frame | Flexible or rigid mesh, snap-in or roll-up |

| Main Material | Aluminum / Stainless Steel, UV-resistant mesh | PVC / Aluminum, fine polyester mesh | PVC, polyester, or steel mesh |

| Corrosion Resistance | Excellent (Salt Spray > 500h) | Good | Fair to Good |

| Mesh Replacement | Semi-Replaceable (depends on model) | Replaceable | Replaceable |

| Energy Saving | Yes, superior sealing, minimized heat loss | No significant effect | No significant effect |

| Applications | Industrial, Commercial, Hospitals, Residential | Residential, Light Commercial | Outdoors, Greenhouses, Farms |

| Service Life | 10-20 Years | 3-7 Years | 2-6 Years |

Parameter Comparison: Service Life & Corrosion Resistance

Expert’s Note: Fixed screen window options provide enhanced energy savings, security, and lowest lifetime cost due to their exceptional material and construction advantages—a conclusion supported by lab and field test reports (see GlassOnWeb Industry Review, 2022).

Customization Services and Industry Applications

- Design-to-Spec: Configurable frame thickness, mesh aperture, corner profile, and RAL powder coating finish to suit precise project requirements.

- Application Environments: Residential buildings (windows, balconies), Commercial (offices, hospitals, schools), Petrochemical & Metallurgy (control rooms, pump stations), Water supply, Wastewater treatment plants, Industrial kitchens.

- Relevant Industries: Construction & Real Estate, Hospitality, Food Processing, Medical Environments, Utilities.

- Custom Mesh Selections: Anti-bacterial mesh, fire-retardant mesh, high-transparency mesh, anti-UV mesh (for sensitive lab/medical use).

- Client Options: 3D digital rendering service, BIM-compatible specs, field measurement and installation instructions.

Application Case Studies: Enhancing Value Across Industries

Requirements: Salt-fog resistance, anti-static, fire-resistant mesh.

Solution: Custom SS304 fixed screen window with FR powder coating; double gasketed design.

Result: Maintained function after >1200h salt spray, 0 reported failures in 6 years.

Requirements: Anti-bacterial mesh, flush sealing to window mullion, easy-clean profile.

Solution: Polyester powder coated aluminum frame, anti-microbe mesh, snap-fit corners.

Result: Passed EN 13561 hygiene audit. Window maintenance time cut by 42%.

Requirements: Custom color frame, magnetic mount, energy-saving.

Solution: RAL-color powder coated fixed screen window with magnetic clip-in.

Result: Energy audit showed 8% thermal saving. Over 2,700 units deployed in 2021–2023.

“All fixed screen window units installed at our chemical plant still look brand-new, even after years in corrosive conditions. This has significantly reduced our maintenance costs.” — Zhang, Facility Manager, Fortune 500 Chemical Co.

Application Distribution by Industry (2023 Survey)

FAQ: Technical Terms & Expert Guidance

Lead Time, Warranty, and Customer Support

- Standard lead time: 7-15 days (standard), 15-30 days (custom specification)

- Warranty: 10 years frame and mesh, ISO/ANSI certified

- Technical support: Online, phone, and on-site options (global)

- After-sales service: Mesh replacement & frame repair available, express dispatch

- Factory tour & project references: Available on request; NDA and confidential project experience as needed

Conclusion & References

The fixed screen window continues to evolve as a critical solution in modern construction, driven by advancements in precision manufacturing, compliance with stringent global standards (ISO, ANSI, EN), and an accelerating demand for customization and energy efficiency. For in-depth perspectives and knowledge, see:

- GlassOnWeb: Fixed Screens—Comparative Durability & Industry Trends (2022)

- Fenestration Forum: Technical Review—Fixed Insect Screen Specs & Standards

- ScienceDirect: Energy Efficiency of High-Performance Windows

- AAMA/ANSI Standards Portal

- ISO 9001:2015 Quality Management Standard

For the latest trends and more fixed screen window innovations, consult recognized industry forums and journals.

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025