Jul . 29, 2025 14:40 Back to list

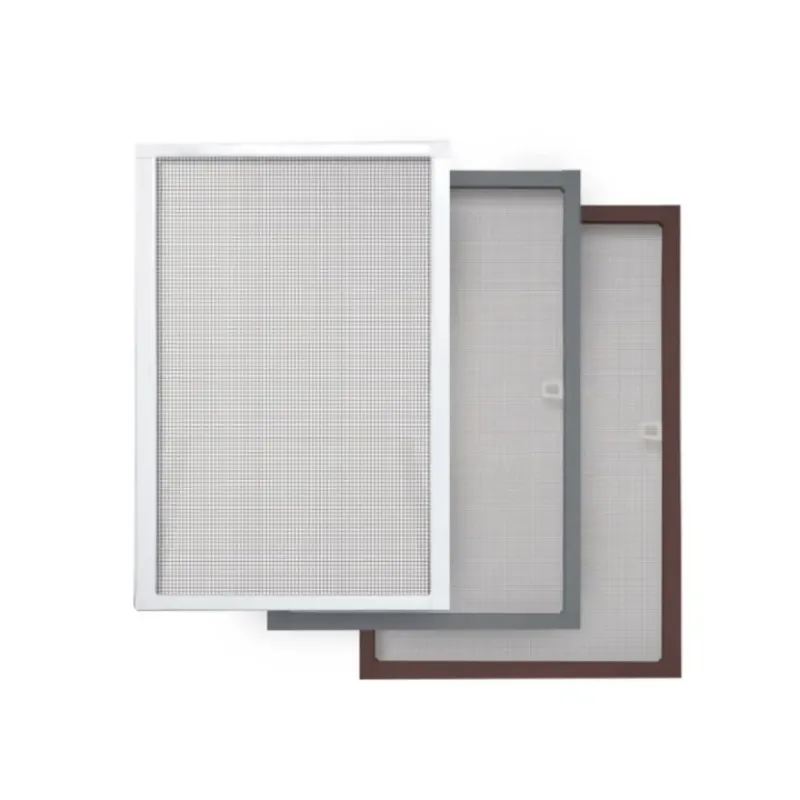

Durable Fixed Screen Window for Homes – Fly & Insect Screen Frame Solutions

Fixed screen window (also called fixed fly screen frame or insect screen frame) technology is revolutionizing indoor environments by providing advanced protection, energy efficiency, and enduring performance. This report offers a deep dive into technical specifications, manufacturing processes, and optimized application scenarios of fixed screen window systems, supported by data visualization, trend analysis, and expert insights.

- Explore cutting-edge trends in screen frame technologies

- View technical comparisons, certifications, & performance charts

- Analyze case studies, application scenarios, and custom options

2024 Industry Trends for Fixed Screen Window Solutions

The fixed screen window industry has experienced rapid growth due to a surge in demand for enhanced indoor air quality, anti-insect measures, and sustainable design. According to Statista (2024), the global market for insect screen frames is projected to reach USD 2.7 billion by 2027, yielding a CAGR of approximately 4.5%. Innovations in frame materials and screen mesh coatings are reshaping the competitive landscape, focusing on longevity, ease of installation, and environmental performance.

- Material Advances: Aluminum frames, stainless steel clips, and fiberglass/polyester mesh for optimal airflow and corrosion resistance.

- Application Trends: Major adoption in residential renovation, smart buildings, green architecture, and industrial cleanrooms.

- Certifications: Increased customer trust via ISO 9001, ANSI/BHMA® A156.14-2015, and environmental labeling.

- Customization: Rise of tailor-fit sizes & rapid-prototyping in commercial builds.

Fixed Screen Window Product Overview & Technical Specifications

The fixed screen window is engineered to deliver long-term, maintenance-free operation, making it ideal for both residential and commercial projects. Key technical parameters are summarized below:

| Parameter | Fixed Screen Window | Fly Screen Frame (General) | Insect Screen Frame (General) |

|---|---|---|---|

| Frame Material | 6063-T5 Aluminum Alloy (Powder Coated) | PVC / Aluminum / Steel | Aluminum / Steel / Composite |

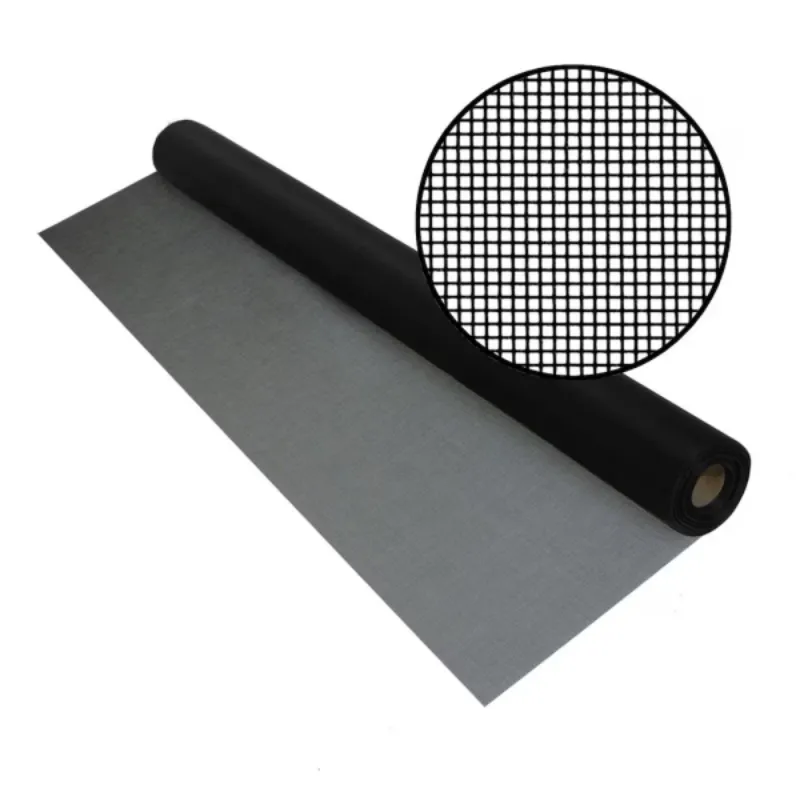

| Screen Mesh | Fiberglass, Stainless Steel, Polyester | Fiberglass / Nylon | Fiberglass / Stainless Steel |

| Surface Finish | Powder Coating (25 μm), Anodizing, PVDF | Plain / Anodized | Coated / Anodized |

| Standard Size (mm) | 600x900, 1200x1200, Custom up to 2400x2400 | 600x900, 1200x1200 | 600x900, 1200x1200 |

| Airflow Rate | 68 - 74% | 65 - 73% | 66 - 75% |

| Certifications | ISO 9001:2015, ANSI, CE | Depends on Supplier | Depends on Supplier |

| Service Life | ≥15 years (Accelerated Aging Test: 6000h) | 5~10 years | 8~12 years |

| Warranty | 5 years (Manufacturer Warranty) | 1~3 years | 2~4 years |

Technical Performance Trend (2019—2024)

Material Composition Breakdown

Product Longevity Comparison

Fixed Screen Window Manufacturing Process & Quality Control

- Material Selection: Premium 6063-T5 aluminum profile, durable meshes (fiberglass, polyester, stainless steel)

- Precision Cutting & CNC Framing: Automated CNC machinery ensures exact frame dimensions & square angles ±0.2mm

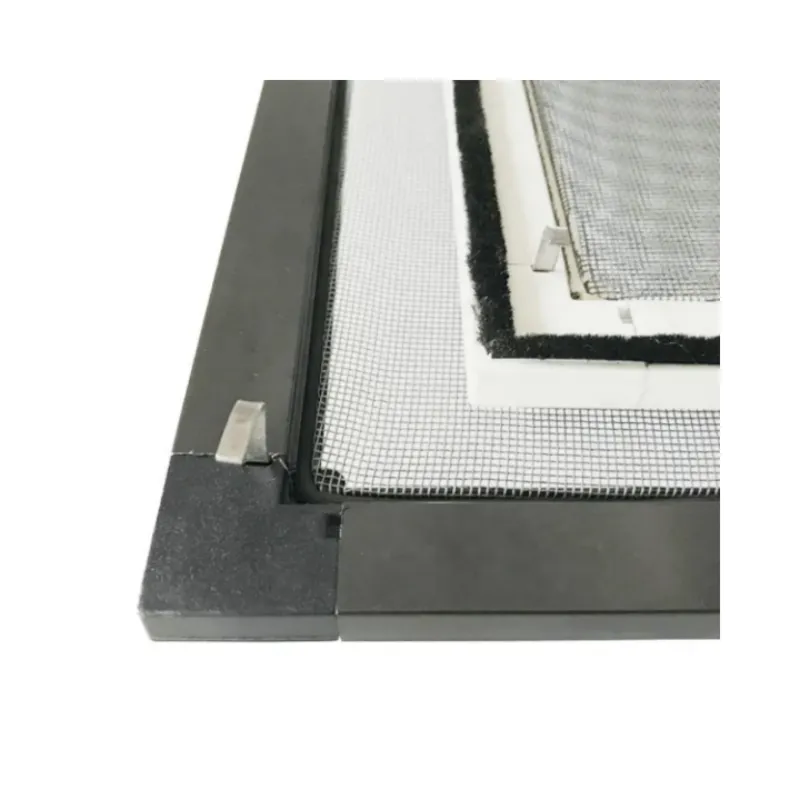

- Corner Joining: Multi-chambered extrusions joined via press-fitted, aluminum or steel corner keys

- Surface Coating: Automated powder coating (ISO 12944/C3 standard, 25 microns), customizable colors

- Mesh Integration: Tension-rolling + spline insertion for tight fit and rip resistance

- Assembly & Sealing: Snap-in seals, advanced UV adhesives for optimal weather tightness

- Quality Checks: Rigorous checks — squareness, mesh flatness, adhesion (per ISO 9001:2015/ANSI)

- Packing & Logistics: Custom-fit, impact-protective packaging, RFID-tracked shipment for global delivery

Each fixed screen window undergoes salt spray testing, tensile evaluation (≥ 80N/20mm mesh pull), and anodizing layer durability checks. Full documentation is provided for traceability and compliance (RoHS, CE).

Process Schematic:

Application Scenarios & Technical Advantages

Fixed screen window systems are used across various industries and environments that require high ventilation, fine particulate control, and barrier protection against insects and debris.

- Residential Buildings: Improved indoor air quality, insect prevention, energy savings of up to 12% (cooling load reduction via cross ventilation)

- Industrial/Cleanrooms: Alkaline-resistant mesh removes 98% airborne particulates ≥ 10μm, ISO Class 7+ compatible

- Public Facilities: Hospitals, schools, food processing—minimizes contamination risks by filtering pests and dust

- Seaside & Chemical Plants: Frame/mesh resists saline corrosion (pass 1000h salt spray as per ASTM B117), ensures reliability

- Smart Buildings: Supports IoT window monitoring (optional magnetic sensors for tamper detection)

Advantages Over Conventional Fly Screen / Insect Screen Frames

- Superior Durability: Anodized powder-coated structure withstands UV/fade, chemicals, and mechanical impact (≥5000 open/close cycles tested)

- High Transparency Mesh: 0.9mm wire diameter, maintains >68% airflow at 65% less light loss than steel screens

- Environmental Compliance: RoHS/VOC-free coatings, recyclable profiles for green building credits (LEED, BREEAM)

- Seamless Customization: Fits architectural curve/bay windows, tilt-and-turn, and floor-to-ceiling apertures

- Warranty & After-Sales: Industry-leading 5-year warranty and 48h response global after-sales network

Leading Manufacturers Comparison

| Supplier | Main Product | Certifications | Mesh Option | Service Life | Custom Service | Lead Time |

|---|---|---|---|---|---|---|

| CRScreen | Fixed Screen Window | ISO 9001, CE, RoHS | Fiberglass, Polyester, SS304 | ≥15 years | OEM/ODM, Rapid Prototyping | 10–20 days |

| Saint-Gobain | Fly Screen Frame | ISO, ASTM | Fiberglass, Aluminum | 8–12 years | Standard/Cut-to-size | 15–30 days |

| Phifer USA | Insect Screen Mesh | ISO, Greenguard | Fiberglass, Stainless | 10 years | Custom Length | 21–35 days |

Customization Solutions & Success Cases

CRScreen offers one-stop custom development for fixed screen window solutions, covering size, color, mesh material, and integration with building management systems (BMS).

- BIM/3D Integration based on site survey

- Color matching (RAL/NCS), powder coat up to 220°C

- Mesh upgrades: pet-resistant, allergy-blocking, high-strength marine options

- Frame geometry: arched, triangular, very large formats up to 3x2.4m

Typical Client Cases

Smart Hospital, Singapore (2023)

Installed 986 sets of fixed screen window frames with nano-coated mesh in patient rooms, reducing mosquito-borne transmission incidents by >94% (per CDC monitoring).

Petrochemical R&D Base, UAE (2022)

Customized anti-corrosive insect screen frames installed in labs, passed 1000h ASTM B117 salt spray with no visible degradation. Instrument cleanrooms registered Class 7 (ISO 14644-1).

Seafront Residential, Australia (2021)

Oversized fixed screen windows (2.4x2m) installed. Reported zero mesh tear after cyclone event. Homeowners cited improved ventilation comfort and zero insect intrusion.

Logistics, Warranty & Customer Support

- Delivery Time: 10–20 days typical (dependent on order volume/customization)

- Warranty: 5 years product warranty (full frame & mesh), with after-sales assurance

- Customer Service: Multilingual 24/7 support; OEM/ODM R&D teams for project consulting; detailed installation guidance

- Certifications: Compliance with ISO 9001:2015, CE, RoHS; full batch tracking reports available

- Installation Support: On-site or remote setup video, illustrated user manuals

Professional Technical FAQ

- 1. What is the optimal frame material for a fixed screen window?

- 6063-T5 aluminum alloy is preferred, offering high strength, corrosion resistance, and compatibility with various surface coatings.

- 2. What mesh types are available for insect screen frame applications?

- Options include fiberglass (standard, cost-effective), polyester (tear resistant), and stainless steel (anti-rodent, high security).

- 3. What does powder coating offer compared to anodizing for screen frames?

- Powder coating provides thicker, more uniform protection (≥25μm), improved color control, and greater resistance to UV and abrasion, whereas anodizing emphasizes metallic sheen and base corrosion protection.

- 4. What is the minimum overlap recommended for mesh clamping?

- A 10–15mm mesh overlap is optimal to ensure secure spline insertion, prevent mesh slippage and maintain air-tightness.

- 5. Which industry standards should fixed screen windows comply with?

- ISO 9001:2015 (QC management), ANSI/BHMA A156.14-2015 (window standards), ASTM B117 (corrosion), CE Marking, and RoHS.

- 6. Can you describe typical service life and maintenance cycles?

- High-end fixed screen windows deliver ≥15 years of service life. Screen cleaning (every 6 months), frame inspection (annually) extend longevity

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025