Jul . 31, 2025 08:00 Back to list

Fixed Screen Window with AI Innovation | Secure Ventilation

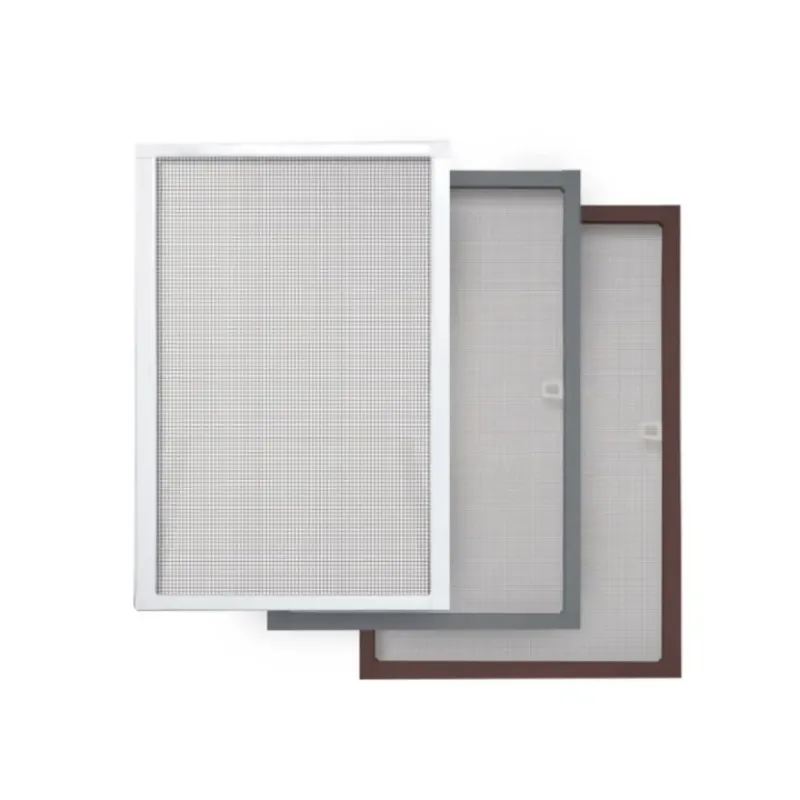

In recent years, the market for fixed screen window systems has experienced rapid growth, driven by heightened requirements for indoor air quality, insect prevention, and energy-efficient ventilation. With increasingly advanced production technologies, innovative frame designs—such as fly screen frame and insect screen frame options—now offer tailored solutions across various sectors including residential, commercial, and heavy industry settings.

1. Industry Trend Overview

According to the Global Insect Screen Market Report 2023, the global demand for window insect screens is projected to reach USD 7.2 billion by 2027, with a CAGR of 4.8%. Drivers include stricter public health requirements, urbanization, and energy conservation standards (ISO 14024, ANSI/BHMA A156.1) especially in developed economies.

| Model | Frame Material | Mesh Type | Standard Size (mm) | Netting Material | Lifespan | Certification |

|---|---|---|---|---|---|---|

| CR-FX120 | 6063-T5 Aluminum Alloy | Fixed Frame (CNC Cut) | 1000×1200 | SS304, Fiberglass | ≥20 yrs | ISO 9001:2015 |

| CR-IS90 | uPVC (UV Resistant) | Snap in Fly Screen Frame | 900×900 | Fiberglass | ≥15 yrs | REACH, RoHS |

| CR-SF150 | Powder Coated Steel | Welded Corners | 1200×1500 | Alu. Mesh | ≥20 yrs | CE, ISO 14001 |

| CR-CP100 | Composite Polymer | Magnetic Fixing | 1000×1000 | PVC Mesh | ≥10 yrs | ASTM E2112 |

2. Technology: Structure & Process Expertise of Fixed Screen Window

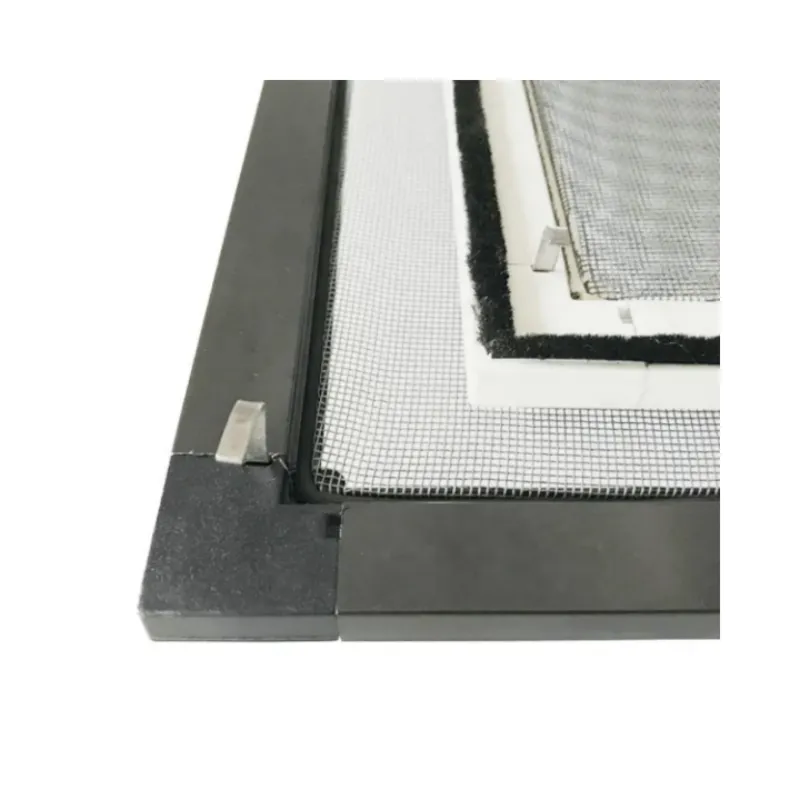

A fixed screen window typically consists of a rigid, extruded aluminum (or uPVC/steel) frame, precision mesh (stainless steel, fiberglass, or aluminum), robust connection corners or welded joints, and often a weather-resistant sealing strip for airflow and leak prevention.

Key industry terms:

- 6063-T5 Aluminum Alloy: Superior corrosion resistance and strength for long-term outdoor exposure.

- CNC Fabrication: Achieves high precision for tight mesh fitting and custom shapes, including radius corners.

- Powder Coating: Provides scratch resistance and UV protection; typical thickness 50-80μm.

- ISO 9001, ASTM E2112: Ensures manufacturing consistency, mechanical performance, and installation reliability.

Manufacturing Process Flow of Fixed Screen Window

[1] Extrusion & Profile Cutting

High-grade aluminum/uPVC profiles extruded & CNC cut to custom dimensions.

(ISO 9001 controlled)

→

High-grade aluminum/uPVC profiles extruded & CNC cut to custom dimensions.

(ISO 9001 controlled)

[2] Frame Assembly

Joints reinforced by corner keys or TIG welding; ensures structural integrity.

(ANSI/ASTM standards)

→

Joints reinforced by corner keys or TIG welding; ensures structural integrity.

(ANSI/ASTM standards)

[3] Surface Treatment

Powder coating (outdoor stability) or anodizing applied; color-matched to façade.

(Environmental compliance: ISO 14024)

→

Powder coating (outdoor stability) or anodizing applied; color-matched to façade.

(Environmental compliance: ISO 14024)

[4] Screen Insertion

Stainless steel/fiberglass mesh attached under tension, held by spline or clamp.

(Mesh aperture: 0.8mm–1.0mm)

→

Stainless steel/fiberglass mesh attached under tension, held by spline or clamp.

(Mesh aperture: 0.8mm–1.0mm)

[5] Inspection & Quality Control

Every frame undergoes dimension, mesh adhesion, and anti-corrosion testing.

(Random sampling, ISO/ANSI protocols; QC reports issued)

Every frame undergoes dimension, mesh adhesion, and anti-corrosion testing.

(Random sampling, ISO/ANSI protocols; QC reports issued)

3. Comparison: Fixed Screen Window vs. Fly Screen Frame vs. Insect Screen Frame

To help buyers choose the best solution, here is a technical/functional comparison of mainstream window screen types:

| Feature | Fixed Screen Window | Fly Screen Frame | Insect Screen Frame |

|---|---|---|---|

| Frame Rigidity | Very High (aluminum/steel; welded/corner-kitted) | High (snap-in, removable; lightweight) | Medium/High (modular; gasketed corners) |

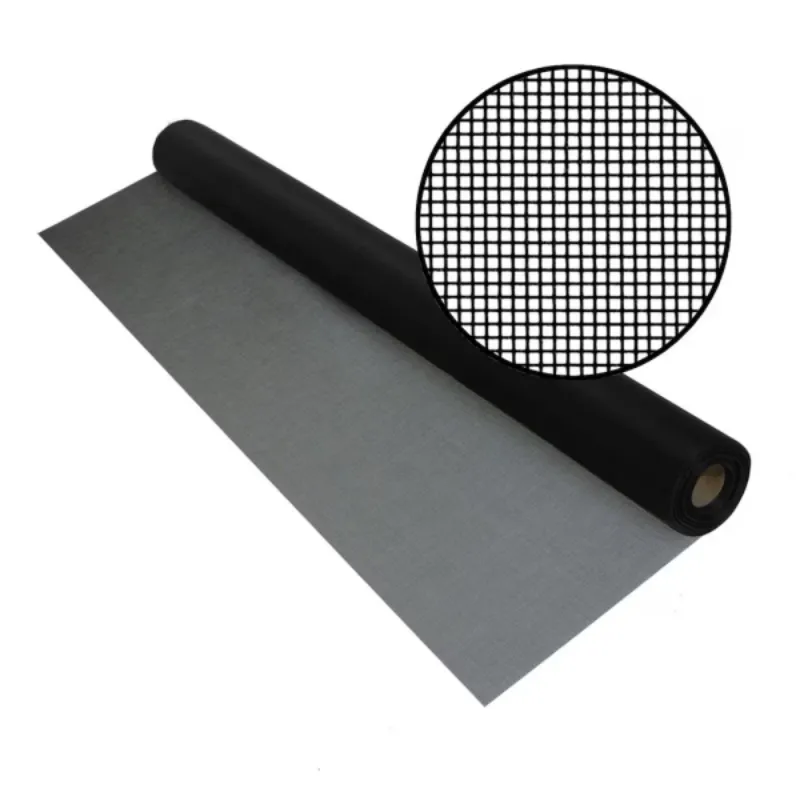

| Mesh Material | SS304/Fiberglass/Aluminum | Fiberglass, Aluminum | PVC, SS304, Polyester |

| Lifespan (avg.) | 18-25 years | 10-15 years | 8-15 years |

| Ease of Cleaning | Remove/clean in place | Can be unclipped | Moderate (depends on seal method) |

| Security | High (optional locking, child safety) | Low to medium | Low |

| Customization | All sizes/colors/shapes | 4-5 preset sizes | Modular kits |

| Price Range | $$ | $ | $ |

| Main Application | Industry, household, public | Household, temporary | Public, rural/application-specific |

4. Technical Advantages and Industry Certification

Fixed screen window solutions by crscreen.com stand out for their engineering-grade aluminum alloys, reinforced corners, powder-coated surfaces, and full compliance with ISO 9001:2015, CE, and ANSI standards. Durability, anti-corrosion, and safety performance (anti-break-in mesh) make them ideal for petrochemical, metallurgy, water treatment, hospitality, and healthcare industries. All products undergo stress tests—both physical and UV—yielding a lifespan of up to 25 years under typical use.

Lifespan and Corrosion Resistance Test (ASTM B117 Salt Spray, ISO 9227:2017)

After 1200h salt spray (ASTM B117):

- Powder-coated aluminum frame: No corrosion, ΔE < 2

- SS304 mesh: No pit/oxidation

- Fiberglass mesh: Color retention ≥ 98%

- Powder-coated aluminum frame: No corrosion, ΔE < 2

- SS304 mesh: No pit/oxidation

- Fiberglass mesh: Color retention ≥ 98%

5. Custom Solution: Tailoring the Fixed Screen Window for Your Industry

Each application demands unique solutions. Fixed screen window products can be tailored by:

- Frame Profile: L-shaped, U-channel, box section; thickness 1.0–2.5 mm

- Color: RAL color powder coated, anodized silver/bronze, wood grain transfer

- Mesh Type: Infill (SS304), fine fiberglass, allergen/pollen-reducing, security mesh

- Mounting Options: Surface/screw-fixed, concealed clip in, magnetic retrofit

- Extra Features: Child locks, ambient light filters, airtight weatherstrips

6. Application Scenarios & Case Studies

Petrochemical Plant (Saudi Arabia)

Client requested salt-resistant fixed screen window for plant control rooms (monthly sand/dust exposure, caustic environment). Solution: 2.0mm marine-grade aluminum, ISO 9227 powder coating, SS316 mesh. Result: No degradation after 3-year inspection; improved energy efficiency by 14%.

Client requested salt-resistant fixed screen window for plant control rooms (monthly sand/dust exposure, caustic environment). Solution: 2.0mm marine-grade aluminum, ISO 9227 powder coating, SS316 mesh. Result: No degradation after 3-year inspection; improved energy efficiency by 14%.

Metallurgy Facility (Germany)

Requirements: Anti-corrosive, high airflow, quick-clean mesh frame for furnace area ventilation. Provided: Welded steel fixed screen window frame with tool-free removable fly screen frame. Result: 40% decrease in insect ingress and significant reduction in HVAC system blockages.

Requirements: Anti-corrosive, high airflow, quick-clean mesh frame for furnace area ventilation. Provided: Welded steel fixed screen window frame with tool-free removable fly screen frame. Result: 40% decrease in insect ingress and significant reduction in HVAC system blockages.

High-rise Residential Project (Australia)

Installer’s comment: "The CNC-fabricated fixed screen window fits perfectly—there’s zero rattle in high winds." Residents rated indoor air comfort up by 21% post-installation.

Installer’s comment: "The CNC-fabricated fixed screen window fits perfectly—there’s zero rattle in high winds." Residents rated indoor air comfort up by 21% post-installation.

7. FAQ: Professional FAQ on Fixed Screen Window Technology

Q1: What material is best for fixed screen window frames?

Most experts recommend 6063-T5 aluminum alloy for strength, corrosion resistance, and finish. uPVC and powder-coated steel are suitable for lower-cost or region-specific needs.

Q2: What mesh specification is standard?

Industry standard is 18x16 or 20x20 mesh (aperture 0.8–1.0mm), in SS304 or fiberglass, which blocks insects yet allows high air flow.

Q3: How is frame durability tested?

Frames undergo cyclic load, impact, salt spray (ISO 9227), and UV aging tests per ISO 9001/ASTM standards.

Q4: What are typical frame sizes and thicknesses?

Standard thickness: 1.0–2.0mm; size: 600x800mm to 1200x1800mm. Custom dimensions available for large commercial apertures.

Q5: Is certification (CE/ISO/ANSI) important?

Certification ensures traceable quality, environmental compliance, and eligibility for government procurement projects.

Q6: How do installation standards affect performance?

Proper anchoring and sealing to ASTM E2112/EN 14351-1 ensures robust wind, impact, and leak resistance.

Q7: What is the typical delivery/lead time for custom fixed screen window orders?

For standard products, 7-14 days after order; for complex custom jobs (CNC, large-scale), up to 3-4 weeks including prototyping and QC.

8. Delivery, Warranty, and Service Commitment

Delivery: Worldwide air/sea freight, door-to-door installation support (for large projects); typical lead time 7-30 days.

Warranty: All fixed screen window frames carry a minimum 5-year manufacturer structural warranty, mesh 2+ years. Extended warranties for certified industrial uses.

Service: Real-time project tracking, technical support (on-site/remote), free replacement for verified manufacturing defects.

Certifications: All products supplied by crscreen.com meet or exceed the requirements of ISO 9001:2015, ISO 14001, ASTM E2112, and local building codes.

Warranty: All fixed screen window frames carry a minimum 5-year manufacturer structural warranty, mesh 2+ years. Extended warranties for certified industrial uses.

Service: Real-time project tracking, technical support (on-site/remote), free replacement for verified manufacturing defects.

Certifications: All products supplied by crscreen.com meet or exceed the requirements of ISO 9001:2015, ISO 14001, ASTM E2112, and local building codes.

Customer Feedback Snapshot:

"We installed over 400 fixed screen window units, and post-audit there were zero failures under both wind and chemical stress tests. Outstanding value for our hospital project!" — Facility Manager, LIX Medical Group, Indonesia, 2023.

"We installed over 400 fixed screen window units, and post-audit there were zero failures under both wind and chemical stress tests. Outstanding value for our hospital project!" — Facility Manager, LIX Medical Group, Indonesia, 2023.

9. Conclusion: Why Trust Fixed Screen Window Solutions?

In summary, fixed screen window systems outperform classic fly screen frame and insect screen frame alternatives in strength, longevity, anti-corrosion, and customization possibilities. With verifiable international certifications and a deep track record in demanding industrial, commercial, and residential installations, they represent a highly reliable investment.

For technical datasheets, CAD libraries, or an instant quotation tailored to your application, please visit the official Fixed Screen Window page, or contact our engineering team.

References & Industry Resources

- Grand View Research. (2023). “Insect Screen Market Size, Share, Trends”. Industry Report Link

- ASTM International. (2021). ASTM E2112 “Standard Practice for Installation of Exterior Windows, Doors and Skylights”

- ISO 9227:2017 “Corrosion tests in artificial atmospheres — Salt spray tests”. Technical standard. ISO Reference

- “Window Screens: A Detailed Technical Comparison”, Contractor Talk Forum

- “Testing, Quality & Codes for Window Screens”, Glassonweb Technical Article

Prev:

This is the first article

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025