Magnetic window net (or magnetic window mesh, magnetic screen window) technology represents a modern, energy-efficient, and user-friendly solution for residential, industrial, and commercial window protection. With the increasing demand for ergonomic, durable, and maintenance-free window screening, these products have become the industry standard across markets.

In this article, we will discuss industry trends, analyze technical parameters, highlight application scenarios, provide in-depth technology and manufacturer comparisons, and share expert insights backed by real-world data, customer experiences, and referenced industry standards.

Industry Trends: The Rise of Magnetic Window Net Solutions

- ➔ Global Magnetic Window Net Market Size reached $750 million in 2023 (Research), expected CAGR of 7.9% through 2030.

- ➔ Residential adoption rate has risen from 32% in 2017 to 58% in 2023 (APAC, US, EU markets).

- ➔ Industrial & commercial use growing, especially in pharmaceutical cleanrooms and food packaging sectors, due to FDA & ISO14644 requirements.

- ➔ **Patent filings** on magnetic screen systems have tripled since 2018, spurring innovation in magnet technology and mesh durability.

- Energy-saving requirements in green buildings (LEED/ISO50001).

- Health & hygiene—compliance with anti-insect and anti-allergen standards (FDA, EN-13561, ISO14644).

- Ease of retrofitting & maintenance, boosting property value.

Technical Parameters: Magnetic Window Net Performance Specification Table

| Parameter | Standard Value | Test Method | Industry Standard |

|---|---|---|---|

| Mesh Material | Fiberglass / 304 Stainless Steel | ISO 9227 Salt Spray Test | ISO 9044, ASTM E2016 |

| Magnet Strength | 3200~4500 Gauss | Fluxmeter Measurement | ANSI B18.32.2 |

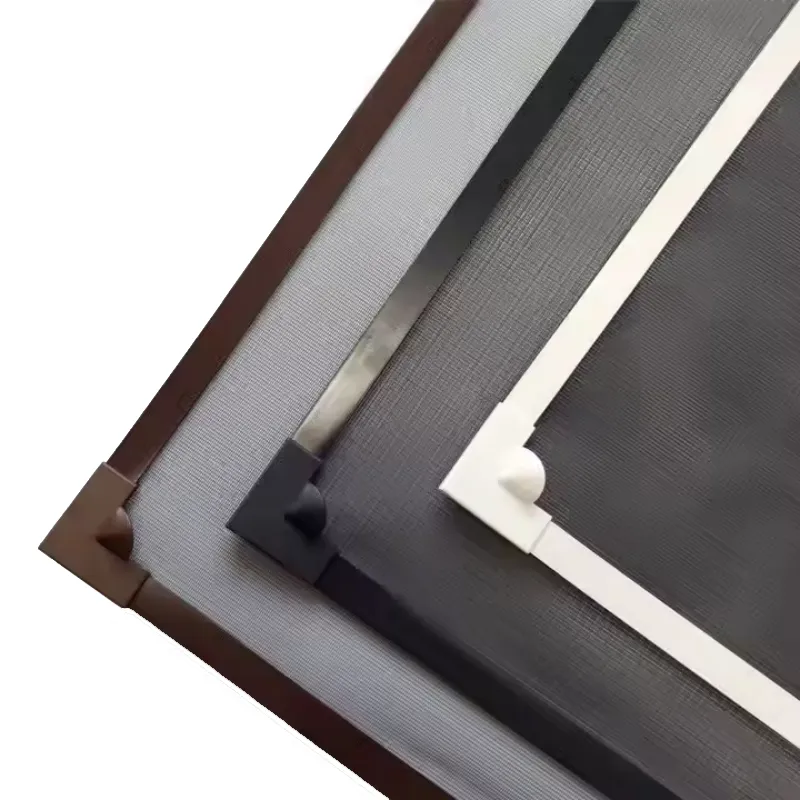

| Frame Material | Aluminum Alloy / PVC | Tensile & Salt Spray | EN 573, ISO 7599 |

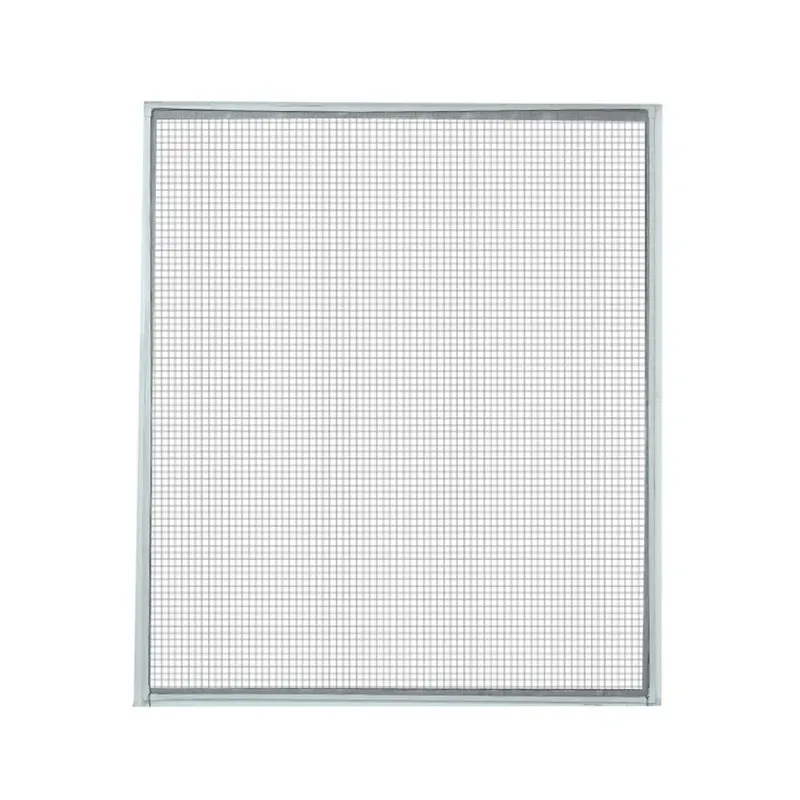

| Mesh Aperture | 1.2mm–2.2mm | Optical Comparator | ISO 3310–1 |

| UV Resistance | ≥ 4000 Hours | ASTM G154 | ISO 4892 |

| Corrosion Resistance | >500 h | Acetic Acid Salt Spray | ISO 9227 |

| Fire Resistance | Class B | Flame Chamber | UL 94 |

Manufacturing Process of Magnetic Window Net: Flow & Quality Control

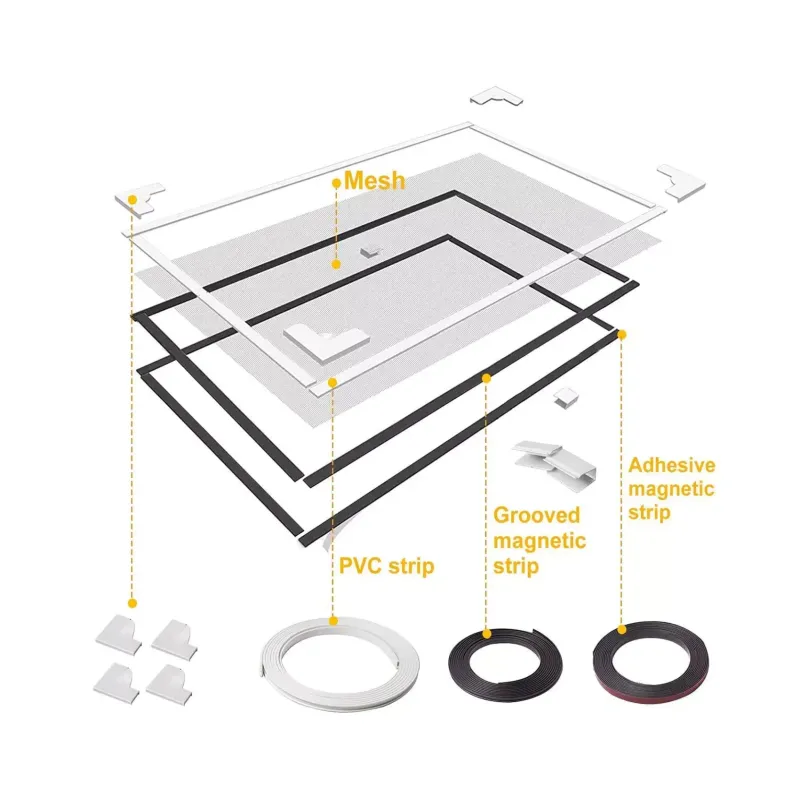

-

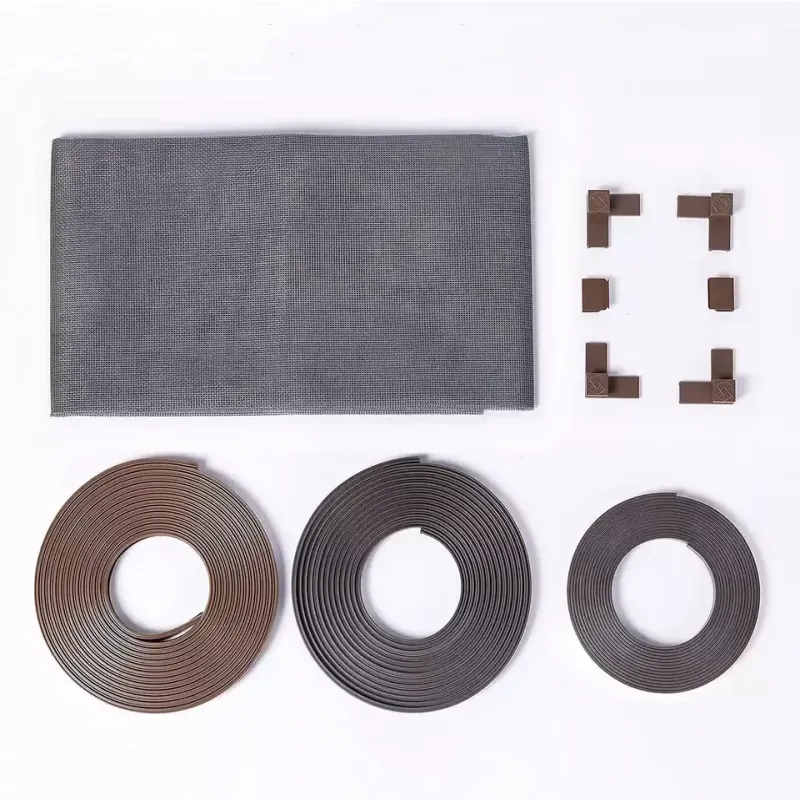

Raw Material Selection:

- Fiberglass, 304/316 stainless steel wire—ISO 9044, FDA-approved.

- High strength N35~N52 rare earth magnets.

- Architectural grade aluminum alloy/premium PVC frame.

- Screen Mesh Weaving: CNC-driven loom, mesh precision ≤ 0.02mm, (ASTM E2016 certified).

- Frame Extrusion/Injection Molding: EN 573 aluminum or ROHS PVC, CNC cutting, ISO 7599 anodizing.

- Magnet Embedding: Magnetic strips inlaid/sealed by high-speed automation, flux testing (ANSI B18.32.2).

- Corner Splicing & Gluing: High-tack adhesives (ISO 11339), 48H peel force test.

- Final Assembly & QC: Dimensional check, mesh tightness, snap/peel force, full-cycle life simulation (ISO 9001, ISO 9227).

- Packing & Traceability: QR code trace, anti-static/UV packaging, ISO 2859 sampling.

Product Comparison: Magnetic Window Net vs. Conventional Screens

| Magnetic Window Net | Traditional Aluminum Screen | Velcro Screen | |

|---|---|---|---|

| Installation | Tool-free, Snap-in 5min | Screw-in, 20–40min | Peel & Stick, 10min |

| Durability | 15~20 years | 7~12 years | 2~4 years |

| Magnetism | YES (3200–4500 Gauss) | NO | NO |

| Detachment/Reinstall | Easy, repeatable | No, complex | Limited cycles |

| Anti-Corrosion | ISO 9227 500h+ | 300–550h | 90–120h |

| Aesthetics | Invisible, flush | Frame visible | Obvious tape |

| Certifications | ISO, ANSI, FDA | ISO (Basic) | None |

Global Manufacturer Comparison

| Brand | Main Market | Certifications | OEM/Customization | Warranty | Installation Support |

|---|---|---|---|---|---|

| CRScreen | Global (APAC, EU, US) | ISO 9001, ISO 9227, FDA | Yes | 5 Years | Manual/Online |

| Phifer | US, Canada | ISO 9001, EPA | No | 3 Years | Manual |

| Smartex | EU, ME | ISO 9001, ROHS | Limited | 2 Years | Manual |

Key Performance Data Visualization

( Magnetic Window Net vs Others)

Custom Solutions: Adapting Magnetic Window Mesh For Every Industry

- Petrochemical: Highly corrosion-resistant mesh, fire-retardant PVC, used in ISO 14644 certified cleanrooms.

- Metallurgy & Power Plants: Stainless steel mesh, >20,000-cycle mechanical test, oversized frames, electromagnetic compatibility.

- HVAC & Waterworks: Antimicrobial mesh (EPA & FDA certified), UV-stabilized magnets, for ventilation hatches.

- Food & Pharma: FDA food-grade, easy-to-clean, no-particle-shedding design, passivation finishing (ASTM A967).

- Education & Healthcare: Child-safe corners, anti-pinch strips, quick-detach for hygiene.

● Mesh opening, wire diameter, magnet layout

● Frame color (RAL classic & custom), UV, anti-smog, or extra-strong magnets

● Specialized gaskets and installation hardware for non-standard windows

Application Cases & Client Testimonials