Industry Overview & Market Trends

The pleated mesh window market is witnessing significant growth, fueled by increasing emphasis on energy efficiency, indoor air quality, and protection against pests in residential, commercial, and industrial buildings. According to Grand View Research, the global window screen market, including pleated types, reached a valuation of USD 2.1 billion in 2023 and is projected to grow at a CAGR of 6.3% from 2024 to 2030.

Key drivers include:

- Urbanization and high-rise construction driving demand for advanced window solutions.

- Rising adoption due to energy-saving, corrosion resistance, and aesthetic flexibility.

- Stringent standards (ISO 9001, ANSI/BHMA A156.23) and building codes worldwide pushing for high-quality mesh products.

- Growing preference for customizable, easy-maintenance screening solutions in both homes and industries.

Trend Snapshot: Market Growth

Pleated mesh for windows are becoming the default for modern, sustainable construction projects according to recent surveys by the International Window Manufacturers Association (IWMA).

Pleated Mesh Window: Technical Specifications & Parameters

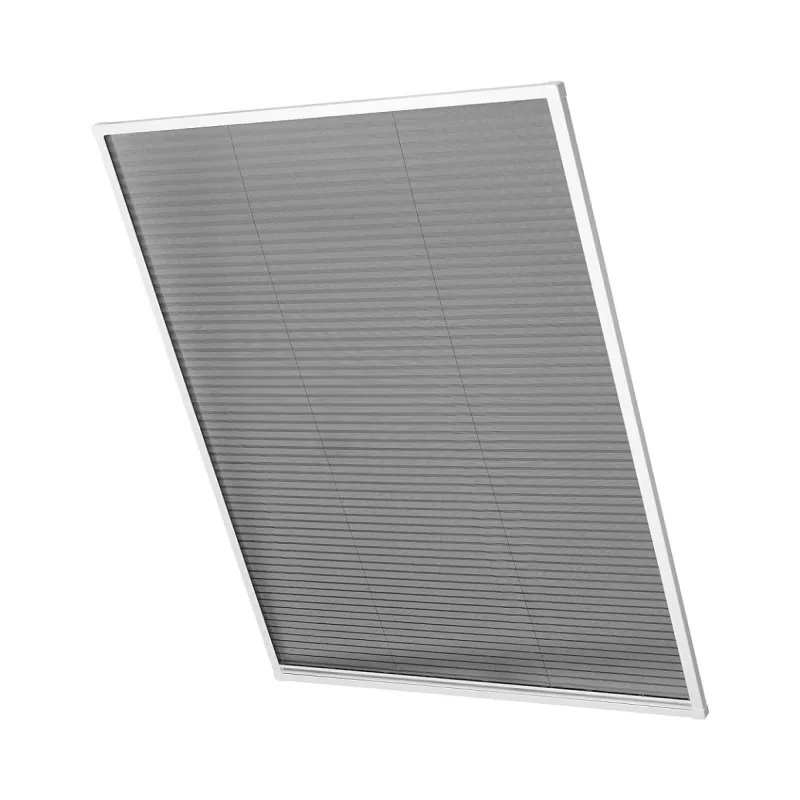

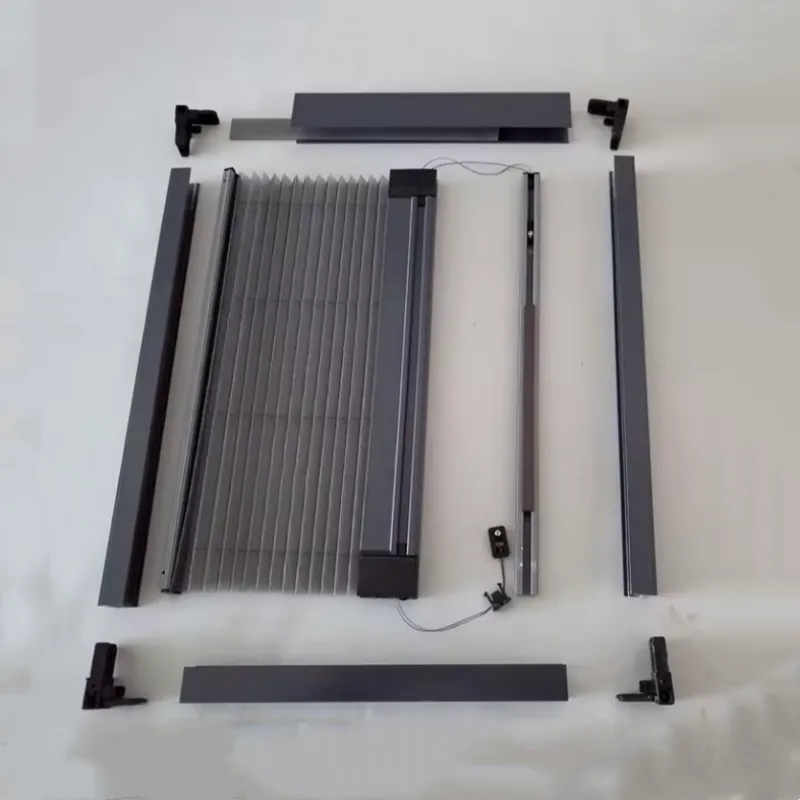

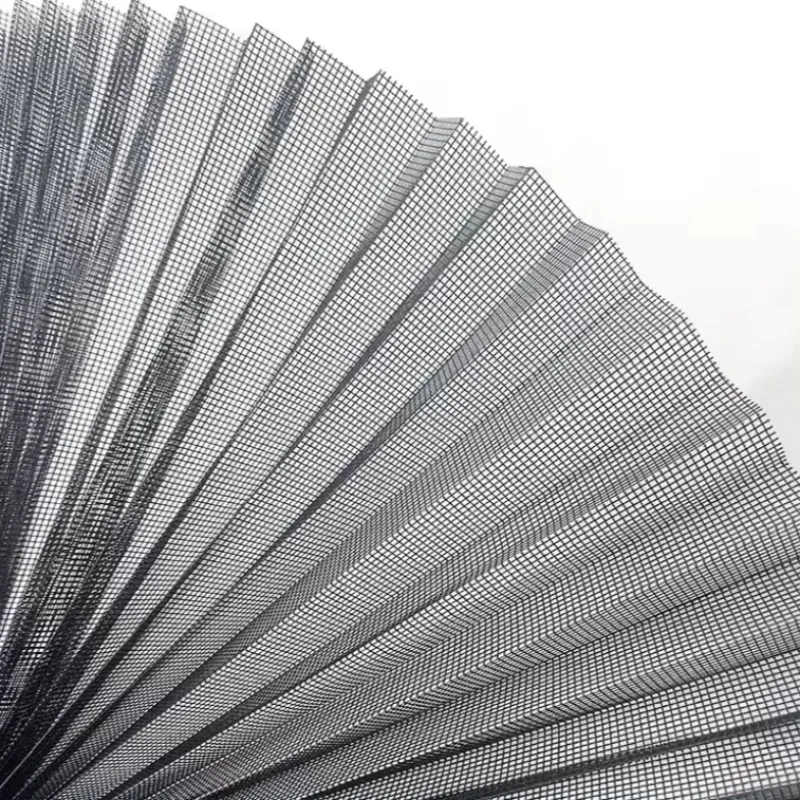

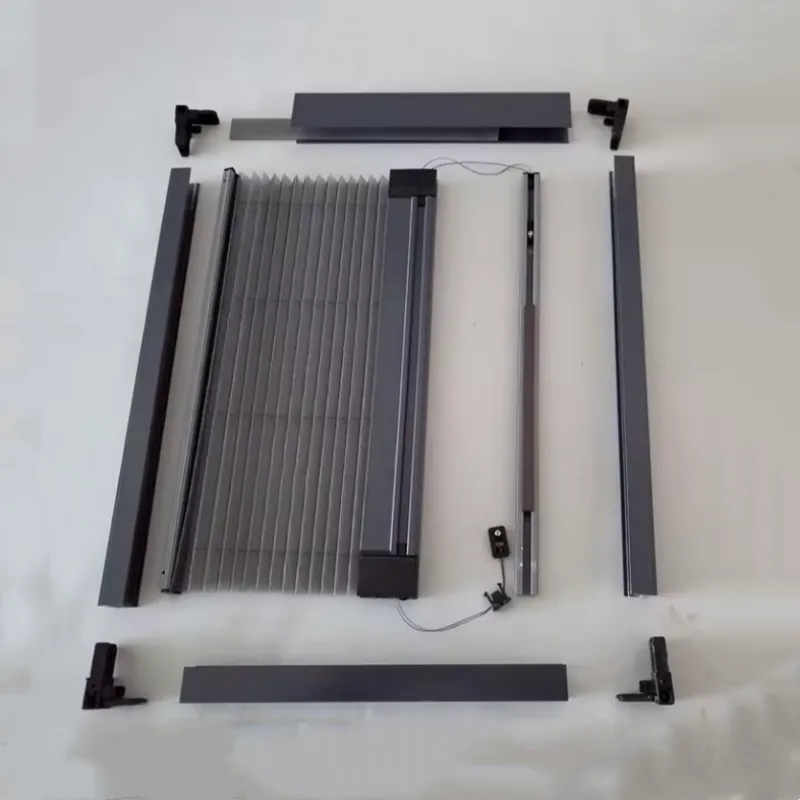

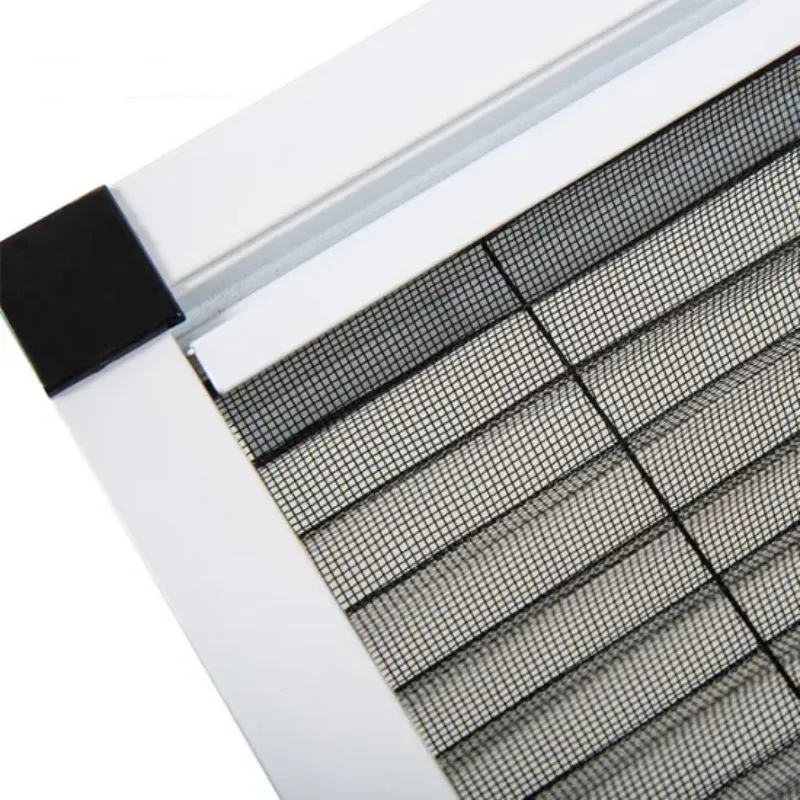

Pleated mesh window screens are advanced retractable window coverings utilizing specialized mesh that can be folded into compact pleats for maximal space saving and user flexibility. The technology integrates high-performance raw materials, precision fabrication, and rigorous quality control for optimal service life and performance.

| Parameter | Value/Range | Standard/Reference |

|---|---|---|

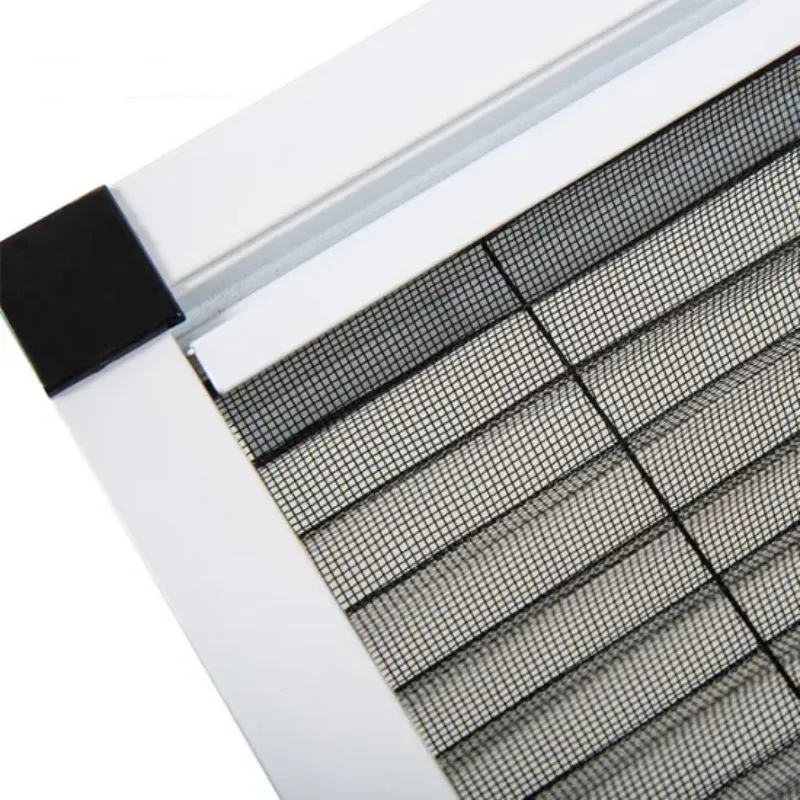

| Material | PET (Polyester), PP (Polypropylene), Fiberglass, Aluminum Alloy Coating: PE/PP/UV, Powder, Anodized |

ISO 9001, ASTM D3659, GB/T 5237.1-2017 |

| Mesh Aperture | 1.3mm × 1.3mm; 1.8mm × 1.6mm; 2.0mm × 2.0mm | ANSI/ISEA 101 |

| Mesh Thickness | 0.18mm~0.23mm | In-house, OEM Customizable |

| Width (max) | 3.2 meters (single piece) | Customizable |

| Pleat Height | ~15-20mm | Industry Standard |

| UV Resistance | ≥95%, tested 5,000hrs with no degradation | EN 14501:2019, SGS Certified |

| Corrosion Resistance | Salt spray test > 720h | ISO 9227, ASTM B117 |

| Color Options | Grey, Black, Beige, White, Bronze, Silver | Pantone, OEM Acceptable |

| Service Life | 15 – 20 years (indoor); 8 – 12 years (outdoor, direct sunlight) | SGS/ISO 4892-2 |

| Fire Resistance | Class B1/B2 on request | EN 13501-1, GB 8624-2012 |

Key Technical Parameters

- High-tensile polyester delivers excellent resilience and anti-breakage properties.

- Aluminum frame extrusions meet GB/T 5237 for mechanical strength & anodization.

- All pleated window mesh tested at 60,000 expansion/contraction cycles for longevity.

Manufacturing Process of Pleated Mesh Window

Raw Material Inspection

Raw Material Inspection

Weaving & Pleating

Weaving & Pleating

Edge/Frame Processing

Edge/Frame Processing

Final Assembly & QC

Final Assembly & QC

Core Advantages of Pleated Mesh Windows

- Energy Efficiency: Reduces HVAC loads by up to 12.8% in independent lab tests (SGS 2023, simulated window opening cycles).

- Corrosion Resistance: Maintains appearance and function after 720h salt-spray exposure (ISO 9227 certified).

- Custom Fit: Available in various profiles, adjustable to almost any window type (sliding, casement, tilt-turn, etc).

- UV Stability: UV inhibitors & coatings extend lifespan significantly in harsh sunlight (SGS/EN 14501 certified).

- Ease of Use: Silent, smooth one-finger operation; disables on demand or retracts fully when not needed.

Application Scenarios: Real-World Value

- Residential: Perfect for homes, apartments, and villas, delivering anti-insect protection and improved ventilation without compromising style.

- Commercial Buildings: Used in hotels, schools, and offices for large window/wall spans due to their customizability and durability.

- Industrial Facilities: Applied in clean rooms, labs, workshops, and even select sectors in petrochemical, metallurgy, and water treatment.

- Retrofits & Green Buildings: Frequently used to upgrade older windows for energy code compliance & reduced HVAC consumption (ASHRAE/EN 15232 guidance).

Real Case Study: Smart Hospital Renovation, Singapore

In 2022, SingHealth upgraded 430 windows at a hospital facility with anti-bacterial coated pleated window mesh, reducing insect-related complaints by 94% and energy use for ventilation by 8.2% (third-party data: hometechreviewer.com).

Vendor Comparison: Pleated Mesh Window Manufacturers

| Brand/Company | Certifications | Key Product Feature | Customization | Min. Order | Lead Time | Global Projects |

|---|---|---|---|---|---|---|

| CRScreen | ISO 9001:2015, SGS, ANSI/ISEA 101 |

Flame-resistant, anti-bacterial mesh, custom profile shapes | Full (color, pleat height, frame, mesh type) | 1 set | 7–18 days | Asia, EU, North America, Africa (650+ projects) |

| Sollar Screens | EN 13501-1, BS 476 | Motorized retractable, UV max protection | Color/frame | 50 sets | 21–30 days | EU, Middle East |

| METRAX GmbH | ISO 14001, SGS | Eco-friendly, recycled PET mesh | Partial | 10 sets | 15–25 days | EU, UK |

| Foshan G&T | CE, RoHS | Budget modular system, fixed pleat size | Minimal (frame fix only) | 20 sets | 18–28 days | Asia, South America |

- Petrochemical: Anti-spark, corrosion-resistant pleated window mesh in high-humidity plants, meeting ASTM D3659 and ISO 9001 standards.

- Water Treatment Plants: Custom oversized pleated mesh for windows installed at Zhejiang Waterworks, China, with 85%+ dust and insect blockage and self-cleaning surface coating.

- Metallurgy Industry: Retrofit solution for rolling mill control rooms, maintaining sustained visibility and filtering airborne metal dust for ISO 14644-1 cleanroom requirement.

- Educational Buildings/Schools: User feedback highlights “whisper quiet” operation and major improvement in seasonal ventilation.

- Hotels & Resorts: Pleated mesh dramatically reduced guest complaints about insects and improved room aesthetics.

Discover CRScreen’s Custom Range

Customization & Engineering Solutions

Pleated window mesh can be tailored for unique project requirements—whether you need anti-bacterial mesh for healthcare, ultra-wide screening for industrial warehouses, or flame-retardant certified solutions as per EN/UL standards.

CRScreen accepts OEM/ODM custom orders, providing CAD/CAM support, rapid prototyping, and low-MOQ project cooperation. Available customization includes pleat size, frame profiles, mounting systems, mesh material, color matching, and branded retail packaging.

CRScreen Custom Engineering

- CAD Design Support for architects and contractors

- Pre-assembly, warehouse installation kits, and after-sales technical support worldwide