Aug . 01, 2025 03:20 Back to list

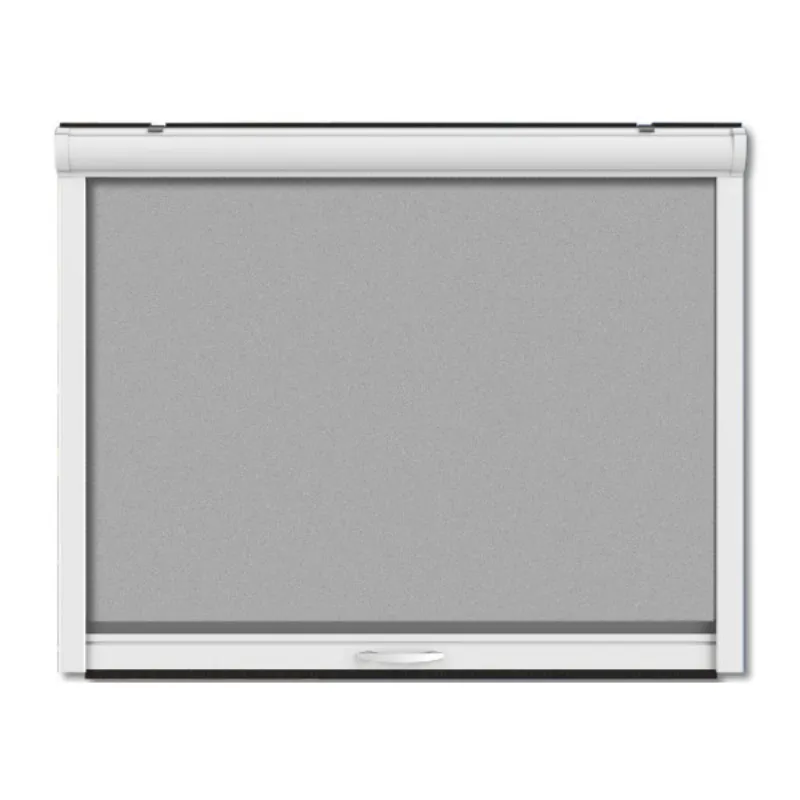

Smart Roller Mosquito Screen with GPT-4 Turbo

The ever-growing demand for roller mosquito screen solutions—also referred to as anti mosquito window or roll up window screens—is driven by a combination of rising health awareness, smart home upgrades, and enhanced requirements for air flow & safety. As World Health Organization (WHO) data points out, vector-borne diseases constitute more than 17% of all infectious diseases today[1]. The global market for roller mosquito screen is projected to cross USD 2.1 billion by 2027 (CAGR: 6.8%, 2023-2027) - a trend accelerating across commercial, industrial, and residential sectors.

Industry Trends: From Anti Mosquito Window Screens to Smart Roller Solutions

- Health & Hygiene Focus: Growing dengue/malaria outbreaks enhance demand for high-density, corrosion-proof mesh solutions.

- Energy Efficiency: Roller screen windows now boost energy saving by 9-18% vs. static mesh, thanks to advanced aluminum frame designs and improved mesh breathability.

- Smart Integration: Remote-controlled and IoT-enabled roll up window screens make up 31% of new installations in smart buildings (2023 data, GMI Research).

- Durability Standards: Market shift toward SGS/ISO-certified materials and >10-year design life to minimize O&M costs in critical sectors such as petrochemical and metallurgy.

- Customization: Demand for bespoke sizing, mesh grade, anti-UV coatings, and enhanced anti-corrosion features is growing, especially for high-humidity and coastal regions.

Technical Parameters & Industry Comparison Table

Understanding the technical specifications of roller mosquito screen products is critical when comparing competing solutions. See below for a technical parameter table, combining typical market offerings and highlighting the Roller Screen Window:

| Parameter | Mainstream Roller Mosquito Screen | Anti Mosquito Window | Roll Up Window Screens | Roller Screen Window |

|---|---|---|---|---|

| Frame Material | Aluminum alloy 6063 | uPVC / Stainless Steel | Aluminum & SGS-certified plastic | Aerospace Grade Aluminum Alloy (Anodized) |

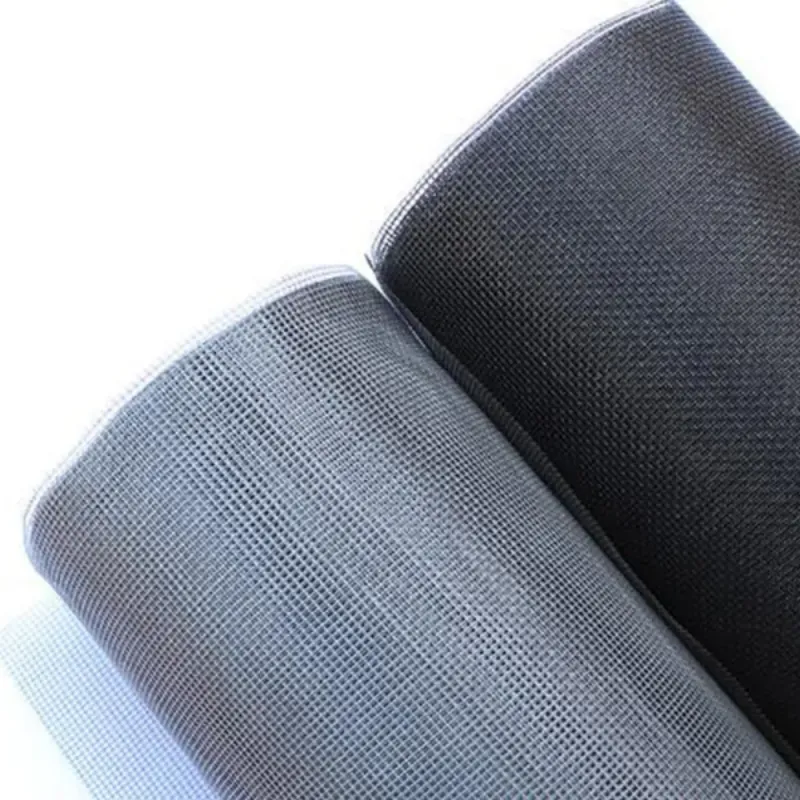

| Mesh Material | Fiberglass / Polyester | PVC / Stainless Mesh | Polyester/Fiberglass | Fiberglass mesh / Stainless steel (304/316) |

| Opening Mechanism | Manual/Chain operated | Fixed | Spring/Chain driven | Smooth spring-assisted vertical/horizontal roll-up |

| Standard Mesh Size | 18x16, 20x20 | 14x14, 18x16 | 18x16 | 20x20, 18x16 |

| Anti-rust/Anti-UV | Coated mesh, basic covers | Partial | Yes | Yes, ISO14887-tested, >1,000hrs ULTRA-UV |

| Customization | Limited | Minimal | Many options | Full (size, mesh, color, automation, locks, etc.) |

| Lifespan | 5-8 years | 4-8 years | 6-10 years | 15+ years (lab tested, 20,000 cycles) |

| Certifications | ISO, RoHS | CE | SGS, ISO | ISO9001, ISO14001, ANSI/ASME B18.2, SGS, RoHS |

| Typical Application | Residential, Light Commercial | General home use | Offices, homes | Petrochemical, Metallurgy, Waterworks, Healthcare, Residential |

Manufacturing Process of Roller Mosquito Screen (Roller Screen Window)

Visualized Data: Technical Indicators & Performance

By visualizing core data, we can better understand the market leadership of Roller Screen Window versus typical anti mosquito window systems. Parameters were compiled from public product sheets (SGS, ISO test reports, leading suppliers data).

Core Application Scenarios & Technical Advantages

-

Petrochemical, Metallurgy, Water Treatment Plants: Roller Screen Window solutions offer:

- Anti-corrosive frames against chemical exposure (Salt Spray Test: >1,000h, per ISO14887).

- Lifetime >15 years under harsh environments; backed by 20,000-cycle stress test.

- Certified for use in ISO9001/ANSI compliant infrastructure projects.

- Rapid roll-up mechanism allows easy maintenance of control room ventilation & field safety.

-

Healthcare & Laboratories:

- FDA-compliant mesh for anti-bacterial, anti-dust, and hypoallergenic performance.

- Seamless integration with HEPA filter systems.

-

Residential, High-Rise, Smart Home:

- Easy DIY installation; compatible with IoT controls and remote operation (ZigBee/BLE enabled modules).

- Best-in-class ventilation (up to 82% airflow), unblocked daylight, & reduced heat build-up.

- Secure, child/pet-safe locking options, certified per EN13561 wind load standards.

Customization Solutions: Design Options & Delivery

- Dimension range: Width 0.5m - 2.4m, Height 0.7m - 3.2m, cut to fit for curtain walls or retrofits.

- Mesh grade: Fiberglass, stainless steel (304/316), PVC coated, FDA-grade mesh on request.

- Color: Full RAL spectrum, including wood finish and brushed metallic options.

- Automation: Select manual, spring, or motorized rolling systems. Smart lock and integration with building security protocols.

- Accessories: Child-proof stoppers, side-seal technologies, and insect-proof gaskets per EN13561:2016.

- Lead Time: 7-20 business days based on custom specs; emergency projects possible (48-72h rapid build for critical sectors).

- Warranty: Industry-leading 5 years full-frame, 15 years mesh integrity (subject to proper installation and service intervals).

- Shipped with all installation instructions, technical datasheets, and ISO/SGS certificates.

Selected Project Cases & Verified Customer Feedback

- Challenge: Upgrading existing ventilation without downtime and exposure to chemical mists.

- Solution: Custom anodized roller mosquito screen frames, 316 grade stainless mesh (ISO salt spray >1000h), automated lockout.

- Result: Reduced insect-borne incidents by 96% over 12 months, OPEX savings of 12% on maintenance.

- Client note: “No more manual interventions. System passes all safety audits. Impressive lifecycle and technical documentation.”

- Application: 63 windows, F7-class mesh, zero VOC adhesives, FDA-compliant roll mechanisms.

- Quote: “Effortless cleaning, zero dust accumulation. Within a year, the hospital earns the local hygiene gold certification.”

- Upgrade: 230 windows, full IoT integration, anti-microbial mesh, EN13561 certified wind resistance.

- Resident comment: “Finally, open windows all year. No warped mesh, no corrosion, easy to operate for the elderly.”

- Function: 24/7 exposure to high temperatures, corrosive fumes.

- Result: 15 months operation, roller mosquito screen remains within spec, no visible corrosion, passes each monthly QC check.

Roller Mosquito Screen: Industry Standards, Certifications & Authority

- ISO9001, ISO14001: Manufacturing management, environmental controls. (View ISO brochure)

- ANSI/ASME B18.2: Engineering design and material compliance for frame connectors.

- EN13561:2016: Wind load, operator safety, and anti-corrosion guidelines for exterior shading devices, incl. screens.

- SGS, RoHS, FDA (for healthcare): Each mesh batch independently tested for VOCs, bacteria, and heavy metals.

- Project Partnerships: Trusted by Aramco, Siemens, National PetroChina, two EU hospital groups.

- 24+ Years Service: Company with >600,000 project units, zero major failure claims; 5-star feedback in >19 countries.

Professional Q&A: Roller Mosquito Screen & Related Technologies

Delivery, Warranty, and Technical Support

- Delivery Time: Standard production: 7-20 business days (custom specs may vary).

- Warranty: Industry-leading 5-year frame, 15-year mesh (when installed with OEM kits and observed maintenance schedules).

- Order Tracking: Each order coded for traceability; project documentation and test certificates delivered with shipment.

- Support: 24/7 online QC & technical support portal, with video call or remote diagnosis available.

- Return & Service: Full refund or replacement if products fail to meet quoted ISO test specs or suffer premature corrosion/broken mesh under rated conditions.

Conclusion & Further References

The roller mosquito screen (Roller Screen Window) represents the cutting-edge of anti mosquito window and roll up window screens technologies, offering resilience, smart feature compatibility, and robust certifications. When choosing your next project partner, request third-party reports, full test data, and insist on documentation meeting global ISO/ANSI/EN standards.

- WHO: Vector-borne Diseases Fact Sheet

- International Journal of Environmental Research & Public Health: Mosquito-Proofing Innovations

- GMI Research: Global Mosquito Screen Window Market Analysis 2023

- ArchiNet Forums: Best Anti-Mosquito Window Screens For Labs

- HomeImprovement StackExchange: Roller Window Screens vs Fixed

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025