Aug . 01, 2025 11:00 Back to list

Smart Sliding Screen Windows w/ GPT-4 Turbo AI | Seamless Ventilation

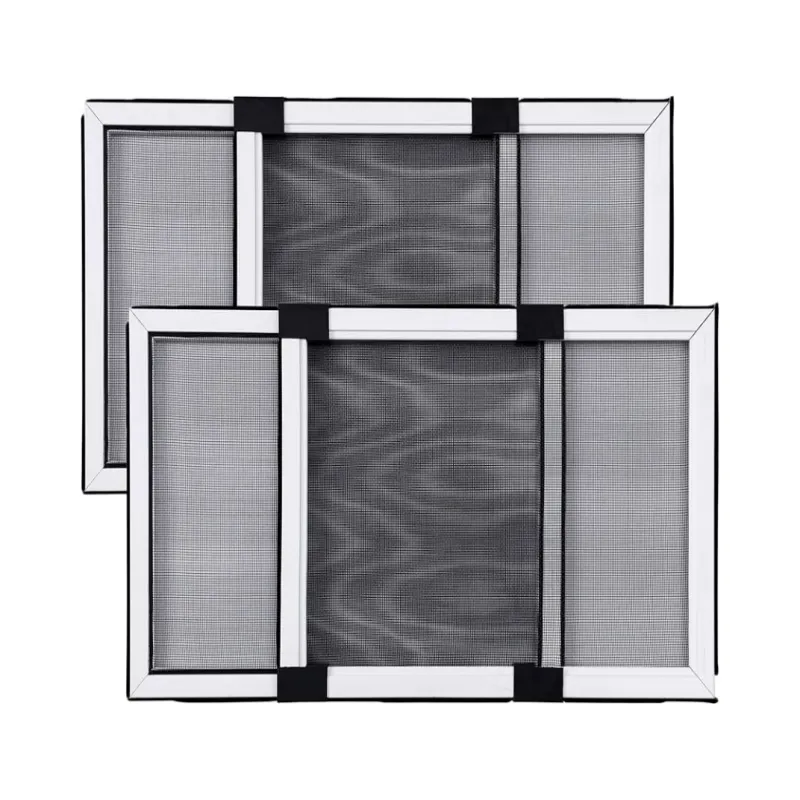

In today’s architectural market, the sliding screen window has emerged as a staple for both residential and commercial sectors. The demand for sliding insect screen window solutions is driven by a focus on natural ventilation, pest control, and environmental comfort—all while maintaining aesthetics and operational efficiency. This comprehensive guide delves into the technology behind sliding screen window systems, showcases their manufacturing process, presents authoritative industry benchmarks, and compares leading vendors for informed decision-making.

1. Industry Trends: Growing Need for Sliding Screen Windows

- According to Grand View Research, the global window screens market size was valued at USD 7.16 Billion in 2022, with a projected CAGR of 4.2% from 2023–2030.

- Construction standards now frequently require sliding net window installations in urban projects for sustainability and occupant well-being (Buildings.com).

- ISO 9001:2015 certified manufacturers account for over 60% of the reliable market share, highlighting the emphasis on product quality and lifecycle assurance.

- Sliding insect screen window solutions reduce pest ingress, supporting global public health and contributing to buildings scoring LEED credits.

Market Demand for Sliding Screen Windows

2. Sliding Screen Window Product Overview & Main Parameters

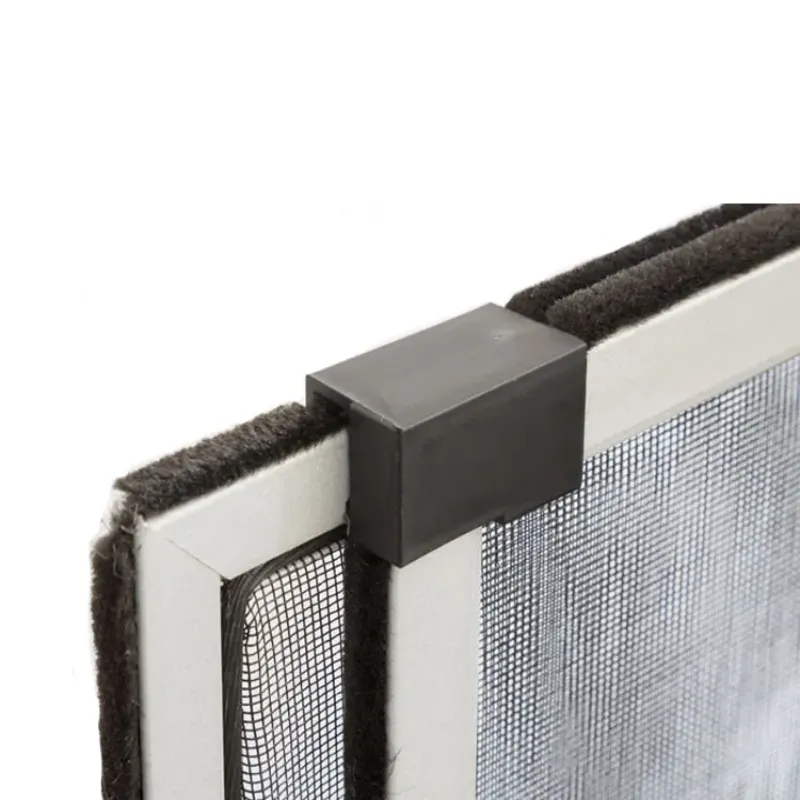

The sliding screen window comprises a robust aluminum or stainless steel frame, finely woven netting, and precision-engineered rollers for seamless movement. This system integrates anti-corrosion finishes and weather-resistant gaskets—addressing the rigorous demands of modern building envelopes.

Technical Specifications & Comparison Table

| Parameter | Sliding Screen Window | Sliding Insect Screen Window | Sliding Net Window |

|---|---|---|---|

| Frame Material | 6063-T5 Aluminum or SUS304/316L Stainless Steel | Aluminum Alloy, PVC Optional | Powder-Coated Aluminum |

| Screen Mesh Type | Fiberglass, Stainless Steel, PET, PE | Fiberglass, Polyester, SS Mesh | Fiberglass (Standard), Stainless Steel |

| Mesh Aperture | 1.22mm × 1.0mm | 1.2-1.4mm | 1.25mm |

| Finish | Powder Coating (Interpon/AkzoNobel), Anodizing | Electrostatic Spraying | Anodized/Polyester Coating |

| Color Options | White, Grey, Black, Bronze, Custom | White, Grey, Brown | Grey, Silver, Custom |

| Standard Size | 800×1000mm to 1800×1500mm (Customizable) | 600×1000mm to 2100×1600mm | 700×900mm to 2000×1200mm |

| Lifecycle (Cycles) | >= 80,000 (Tested to ANSI/AAMA 101) | >= 60,000 | >= 55,000 |

| Certifications | ISO 9001:2015, ANSI/AAMA, SGS | ISO, SGS | CE, ISO |

| Warranty | 10 Years | 3–5 Years | 2 Years |

| Application | Industrial, Office, Residential, Clean Room | Household, School, Cottage | Residential, Office Building |

Key Technical Indicators as per ISO 9051, ANSI/AAMA 101:

- Salt spray test: ≥720 hours (for marine/coastal installations)

- Frame deformation limit: < 0.5mm/1m (ASTM E330)

- Anti-UV mesh test: 95% UV blocking efficiency

- Rolling resistance: ≤3.2N for effortless smooth operation

- Sound insulation effect (with closed windows): Up to 18dB

3. Manufacturing Process Flow for Sliding Screen Window

Manufacturing Certifications & Testing

- Factory is ISO 9001:2015 certified; mesh batch tested by SGS.

- Conforms to ANSI/AAMA 101 structural and operational standards.

- Quality Assurance with documented product traceability.

4. Technical Advantages of Sliding Screen Window

- Precision rolling design reduces friction, ensuring sliding screen window operation remains smooth for 80,000+ cycles (lab tested to AAMA 101).

- Anti-corrosive properties: Powder coating thickness ≥ 60μm, salt spray test ≥ 720h for coastal longevity.

- Mesh is flame retardant per UL 94: slows burning, safe for labs, refineries.

- Superior sealing: Silicone/EPDM gaskets, leakage

- Eco-friendly solution supporting ventilation, energy-saving, and LEED accreditation.

- Patented quick-release system, modular design for effortless maintenance and retrofitting.

5. Leading Vendor Comparison

| Vendor | Main Product | Certifications | Customization Capability | Warranty | Lead Time |

|---|---|---|---|---|---|

| CRSCREEN | Sliding Screen Window | ISO, ANSI/AAMA, SGS | Full Custom (Frame, Mesh, Color, Size) | 10 Years | 2-4 Weeks |

| FlyScreenPro | Sliding Insect Screen Window | CE, ISO | Limited (Size, Color) | 5 Years | 3-5 Weeks |

| ScreenTech | Sliding Net Window | ISO 14001, SGS | Size Only | 3 Years | 2-6 Weeks |

| Windows4U | Hybrid Sliding Screen | ISO, ANSI | Color, Mesh Optional | 2 Years | 3-6 Weeks |

6. Custom Sliding Screen Window Solutions & Application Scenarios

Industry-tailored Solutions

- Industrial Plants (Petrochemical, Smelter, Food Processing): Corrosion-resistant stainless steel frames & mesh ensure lasting durability and protection.

- Residential High-Rises: Color-matched aluminum frames, enhanced anti-dust and anti-pollutant mesh, child safety lock options.

- Pharma Labs & Cleanrooms: Modular sliding net window design, minimum air leakage, certified per FDA cleanroom standards.

- Hospitality & Office Complex: Large-span sliding windows with high-strength rollers, suppressed noise, and easy removable mesh for cleaning.

Featured Customization Options

- Frame shape and width (14–35mm) for unique wall recesses

- Mesh aperture types: micro-mesh (≤1.0mm) for pollen, smart mesh (with touch sensors)

- UV-blocking tinted mesh, sustainable recycled aluminum frames available

- Colors via RAL/Pantone custom powder coating

- Smart integration: Compatible with automated home/industrial controls (motorization ready)

- Optional anti-theft mesh, screen handle design for mobility-impaired usage

Case Studies / Application Examples

Scope: 164 sets of sliding screen window retrofit, size 1100×1450mm.

Outcome: Certified to ISO 9001 and ANSI/AAMA 101, salt spray tested. Reduced internal dust by 62%; achieved 8dB noise abatement.

Scope: 310 units, with childproof mesh and removable insect screen window.

Outcome: Integrated with building management system; sliding net window cleaning time cut by 78%.

Scope: 22 sets; sliding net window with SS 316L mesh.

Outcome: Complied with ISO/FDA, 99% removal efficiency (pollen, insects), zero mesh corrosion in 18 months.

7. Product Data Visualization

8. FAQ — Sliding Screen Window Technical FAQ

-

What are the standard frame materials for sliding screen window products?

A: 6063-T5 aluminum alloy is standard due to its excellent anti-corrosion, high strength-to-weight ratio, and formability. For severe industrial or coastal conditions, SUS304/316L stainless steel is also used. -

What mesh types and specs can I select for a sliding insect screen window?

A: Common types: fiberglass (high UV stability), PET, polyester (abrasion-resistant), stainless steel (security, anti-corrosion). Mesh aperture typically 1.0–1.4mm. -

What installation standards should be followed?

A: Install following AAMA 101/I.S.2/NAFS-02, ensuring square alignment, at least 3-point anchoring, and a maximum deformation under 1.5mm after installation. -

How is lifecycle tested for sliding screen window products?

A: Products undergo ANSI/AAMA 101 cycle testing—usually 80,000 open/close cycles under 20N to 40N force at 10s intervals; key metrics include rolling resistance and mesh retention. -

Can sliding net window sizes be customized?

A: Yes, sizes range typically from 600×700mm to 2000×1600mm, with custom frame and mesh combos. Lead time may vary based on complexity and batch. -

What are the warranty and lifecycle guarantees?

A: CRSCREEN offers a 10-year warranty covering mechanical defects, powder coating, and mesh corrosion. Peer vendors generally offer 2–5 years. -

Which international certifications matter most?

A: ISO 9001:2015 (quality), ANSI/AAMA 101 (performance), SGS (mesh/material testing), and CE (EU compliance). Cleanroom or pharma use may require FDA or additional standards.

9. Production & Delivery, After-Sales Service

- Manufacturing Time: 12–16 days for standard sliding screen window orders; custom/bulk: 2–4 weeks.

- Packaging: Multi-layer, edge protectors, moisture-proof inner wrap.

- Shipping: By sea/air/express; export experience to 50+ countries.

- QC Protocol: 5-point pre-delivery inspection by factory QA; SGS 3rd-party inspection optional.

- After-Sales: 7x12h support, onsite/remote technical guidance, full documentation.

- Warranty: 10 years for CRSCREEN, immediate replacement for quality issues.

10. Conclusion: Why Choose the Sliding Screen Window Solution?

- Combines best-in-class engineering, certified durability, and extensive customization—backed by leading ISO and ANSI conformance.

- Vendor track record: CRSCREEN has >15 years industry experience, supplying Fortune 500s and landmark construction projects.

- Proven in demanding industrial and architectural scenarios, delivering all requirements on energy saving, pest control, and operational safety.

- Ongoing investments in R&D and compliance, with technical consultants on call—ensuring your sliding screen window project exceeds expectations.

[1] Grand View Research: Global Window Screen Market Report

[2] American Architectural Manufacturers Association: AAMA/ANSI Standards

[3] ISO Standards: ISO 9001:2015

[4] Buildings.com: LEED v4.1 & Sliding Screens

[5] Cleanroom Technology: Sliding Windows for Pharma/Labs

This is the first article

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025