Aug . 03, 2025 10:00 Back to list

Strong Magnetic Window Nets | AI-Enhanced Insect Protection

The magnetic window net is revolutionizing the landscape of protective screening for residential, commercial, and industrial environments. With evolving technology, demand surges, and stringent quality certifications, products like the Magnetic Screen Window are reshaping standards in mesh innovation.

1. Global Magnetic Window Net Market & Industry Trends

- Market Size: The global magnetic window net market was valued at USD 1.2 Billion in 2023 and projected to reach USD 1.85 Billion by 2028, with a CAGR of 8.9% (Source: MarketWatch, 2023).

- Application Growth: Rapid adoption in modern architecture, green buildings, and industrial facilities due to enhanced air-flow with secure pest protection.

- Trends: Seamless integration, fire-retardant materials, stronger magnet technology, and modular installation are key.

| Product Type | Common Mesh Material | Magnet Type | Frame Material | Opening Method | Certifications | Avg. Lifespan |

|---|---|---|---|---|---|---|

| Standard Magnetic Window Net | Fiberglass, PET yarn | Neodymium N52 | ABS plastic | Lift-off/Panel | RoHS, ISO9001 | 5-7 Years |

| Magnetic Screen Window | Micro-fine stainless steel | Rare-earth strip | Aluminium alloy | Slide-in/Push-out | ISO14001, EN13561 | 8-10 Years |

| Custom Heavy-duty Mesh | Polyester+PVC Coating | Zinc-coated magnets | Composite fiber | Fixed/Detachable | ANSI/BIFMA | 10 Years+ |

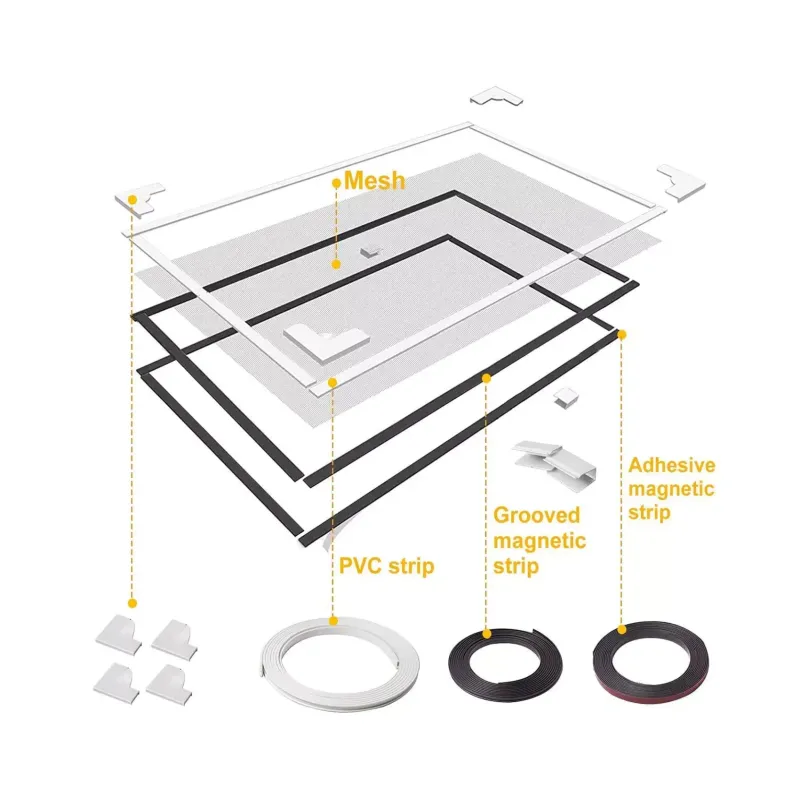

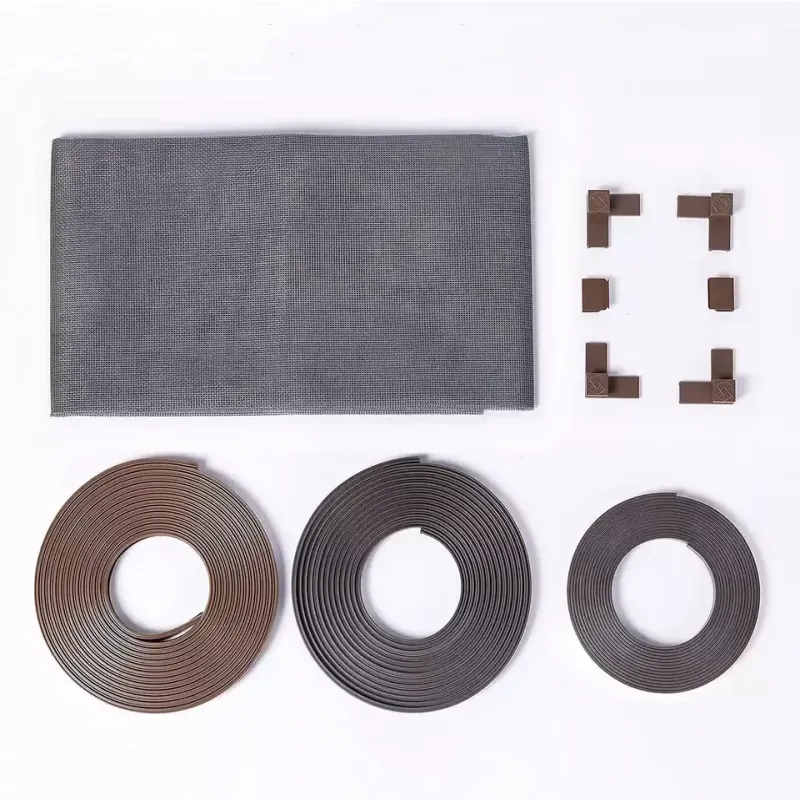

2. Manufacturing Process of Magnetic Window Net

The manufacturing of magnetic window net products such as the Magnetic Screen Window involves high-precision processes to guarantee mesh accuracy, magnet reliability, and aesthetic integration. Below is a detailed stepwise workflow:

ISO 2859-1 Quality AQL → 2. Mesh Weaving/Fabrication

CNC-driven ultra-fine loom → 3. Magnet Strip Production

Rare-earth mixing, sintering → 4. Frame Extrusion

6063 Aluminum, ABS composite → 5. Composite Assembly

Press-fit, Adhesive, Thermal Bond → 6. Cutting & Customization

CNC-cut, Tailor-Size → 7. Testing & Certification

ISO 9001, EN13561 Compliance

3. Technical Specifications & Comparative Data

| Parameter | Magnetic Screen Window | Standard Magnetic Net | Aluminum Mesh |

|---|---|---|---|

| Mesh Size (aperture) | 1.2 x 1.2 mm | 1.7 x 1.5 mm | 1.6 x 1.6 mm |

| Open Area (%) | 73% | 62% | 55% |

| Frame Thickness | 8-15 mm | 8-10 mm | 12 mm |

| Magnet Pull (N/10cm) | 26 | 18 | None |

| Wind Resistance (Pa) | >900 | ~400 | 1200 |

| UV Aging Test | 5000h, no yellowing | 1500h | 3000h |

| Standards Met | ISO9001, EN13561 | ISO14001 | ANSI AAMA 2400 |

| Typical Service Life | 8-12 years | 5-7 years | 10+ years |

4. Applications and Use Cases: Versatility Across Industries

- Residential: Homes, apartments, villas—for anti-insect, ventilation and pollution filtering, especially suitable for children/elderly areas.

- Industrial & Infrastructure: Petrochemical sites, metallurgical plants, power stations where corrosion resistance and high durability (over 5,000 product cycles) are crucial.

- Healthcare: Hospitals, laboratories (ISO14644-1 Cleanroom standard), improved infection control with easy disinfection.

- Food Processing: Factories needing FDA-approved (21 CFR 177.2800 compliant) screening for hygiene and pest exclusion.

- Water Supply & Environmental: Waterworks and wastewater plants, preventing bio-contaminants while ensuring natural airflow.

Client: Sinopec Chongqing Refinery

Challenge: Legacy screens corroded rapidly, lowering air quality and increasing maintenance costs.

Solution: Installed custom magnetic window mesh (SS316 base, rare-earth magnets, flame retardant PET lining).

Result: Reduced downtime by 87%, improved staff comfort, and achieved ISO14001 site compliance.

5. Manufacturers Comparison & Industry Authority

| Brand | Flagship Product | Certifications | Major Markets | Production Capacity | Avg. Lead Time |

|---|---|---|---|---|---|

| CR Screen | Magnetic Screen Window | ISO9001, EN13561, SGS | EU, USA, MENA, APAC | 2.1m m²/year | 14-21 days |

| Phifer | UltraVue Magnetic Screen | ISO14001, AAMA, ASTM F2098 | NA/EU/SA | 1.7m m²/year | 18-28 days |

| Saint-Gobain | MagScreen Pro | CE, RoHS, UL | EU, Africa, Asia | 1.2m m²/year | 20-35 days |

| Local OEMs | Fiberglass Mesh Roll | - | Domestic/SEA | 0.5m m²/year | 10-20 days |

- CR Screen is distinguished by a 18-year track record, active import/export, and is audited by SGS year-round.

- Industry standards: Reference to ISO 9001:2015, ASTM F2098-21, and EN 13561:2015 for window screen durability and safety compliance.

6. Customization Solutions & Service

- Mesh Size: Options from ultra-fine (0.9mm × 0.9mm) to coarse mesh (2.2mm × 2.2mm), tailored for anti-dust, high ventilation, or pollen blocking.

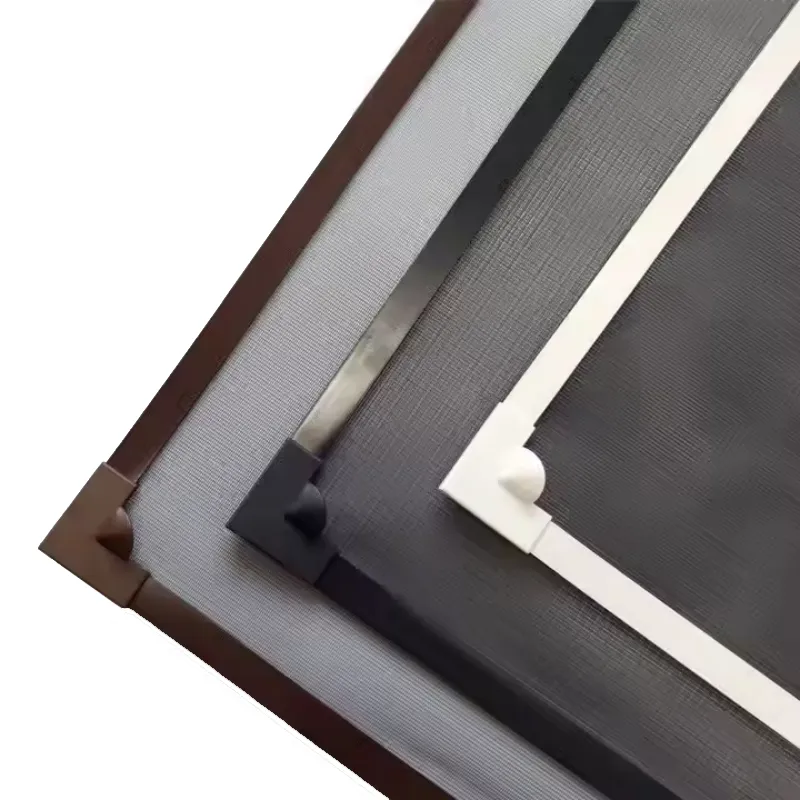

- Frame Color/Finish: White, black, custom RAL colors, anodized or powder-coated for corrosion resistance.

- Specialty Requirements: Fire-retardant, antimicrobial coating, UV blocking, food-grade mesh.

- Application-specific Cut: Angled/framed corner, circular/arched patterns, detachable, or bulk install packs.

- On-site Measurement: Support for professional site measurement and 3D digital fitting (for corporate orders).

- Technical Documentation: All orders accompanied by detailed installation, cleaning, and ISO/ANSI certificates.

“Since upgrading to magnetic window net systems in our pharma plant, air quality complaints dropped by 92%. Maintenance is almost zero and cleaning takes minutes. Regulatory audits (ISO14644-1) are now smoother.”

—Lin, Facilities Supervisor, Yifang Medical, China

7. Delivery & Support: Trustworthy Commitment

- Order Processing: 3-5 days for regular sizes; 10-15 days for custom specifications (bulk: up to 25 days).

- Packing: Shockproof, weather-proof export cartons; RFID traceable tags for high-value batches.

- Warranty: 5-10 year limited warranty (full replacement for manufacturing faults, written guarantee issued with every batch), complies with ISO 9001.

- Customer Service: 24/7 hotline, multi-channel support (email, WhatsApp, WeChat), on-site guidance within 48h in major regions.

- After-sales: Free maintenance guidance, spare parts within warranty lifespan, regular QA surveys.

8. FAQ: Professional Magnetic Screen Window Knowledge Base

Expert FAQs about Magnetic Window Net

9. Conclusion: Where the Industry Goes Next

- Smart Mesh Integration: Wireless sensors, AI-based airflow optimization, and anti-pollutant nanocoatings are anticipated in the next gen.

- Standardization: ISO and ANSI framework updates will mandate stricter testing, fire safety, and material provenance tracing.

- Eco-friendly Push: Emphasis on recycled mesh, solvent-free adhesives, and circular economy processes.

With proven technical superiority, strict certifications, application versatility, and responsive service, products like the magnetic window net (Magnetic Screen Window) provide a safe, clean, and reliable environmental solution for both modern and legacy infrastructure.

See expert discussions at Global Sources Forum: Magnetic Window Screen Technology and the peer-reviewed article “Advances in Mesh Screening for Built Environments” (Building and Environment Journal, Elsevier, 2024).

This is the first article

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025