Jul . 29, 2025 10:00 Back to list

Travel Bug Net – Lightweight Mosquito Nets for Travel Protection

Travel Bug Net & Mosquito Nets for Travel: Industry Trends, Technical Insights & Tailored Solutions

The travel bug net market is rapidly evolving due to increased global travel and the growing demand for healthy, comfortable, and safe environments on the go. Professional travelers, outdoor enthusiasts, and humanitarian workers continually seek high-performance travel mosquito net solutions to prevent insect-borne diseases such as malaria and dengue. This article provides an in-depth analysis of travel bug net technologies, manufacturing processes, and real-world applications, empowering you to make data-driven choices.

View the Travel Mosquito Net Product Detail →

View the Travel Mosquito Net Product Detail →

1. Global Travel Bug Net Market Trends & Industry Insights

Travel bug net and mosquito nets for travel form a crucial sector in the global personal protective equipment (PPE) and outdoor gear industry. According to Statista, the global mosquito net market is projected to reach USD 870 million by 2027, growing at a CAGR of 7.2% driven by increased tourism, government health guidelines, and disease prevention programs.

The major industry trends include:

The major industry trends include:

- Transition from coarse polyester to high-density micro-mesh fabrics

- Integration of water-repellent & antimicrobial coatings

- Popularity of quick-install pop-up travel mosquito net designs

- Upgraded ISO9001:2015 & FDA-tested quality management

- Growing B2B demand from humanitarian groups & disaster relief agencies

2. Travel Bug Net Technical Specification Table (Industry Mainstream)

| Parameter | Value Range | Industry Average | EN / ISO Standard |

|---|---|---|---|

| Material | Polyester / Nylon / Polyethylene | Imported Polyester (60%) | ISO 13934-1 |

| Denier (Thread) | 30 - 75D | 50D | EN 14976 |

| Mesh Density | 156 - 375 holes/in² | 220 holes/in² | WHO Standard |

| Weight | 110 - 190 g/m² | 135 g/m² | ISO 3801 |

| Color Fastness | Grade 3 - 5 | Grade 4 | ISO 105-X12 |

| Coating | None / Water Repellent / Antimicrobial | Antimicrobial (35%) | ISO 22196 |

| Opening Size | Single / Double / King | Single | EN 13537 |

| CBR (Burst Strength) | 6.8 - 15.2 N | 12.6 N | ISO 13938-2 |

| Service Life | 1 - 5 years | 3 years | ISO 19709 |

These parameters demonstrate the multi-faceted engineering behind modern travel bug net design. Denier measures thread fineness; high mesh density blocks most mosquitoes (measured per WHO guidelines); CBR burst strength reflects durability under impact. Chemical coatings meeting ISO 22196 or ISO 18184 ensure verified antimicrobial activity, keeping users protected longer.

Technical Parameter Evolution - Travel Bug Net (2015-2024)

3. Manufacturing Process of Travel Bug Net: From Raw Yarn to High-Tech Protection

Raw Material Selection

(High-Tenacity Polyester/Polyamide, Cert: ISO 9001:2015) → Yarn Spinning & Twisting

Automated CNC Spinning; Uniform 50D/75D threads. → Warp Knitting or Raschel Weaving

Creating uniform mesh (WHO, EN 14976). → Chemical Coating

Antimicrobial & Water Repellency; Verified ISO 22196/ 18184. → CNC Cutting & Final Sewing

Precision laser cut, reinforced seams (ISO 13938-2). → Inspection & Packaging

Tensile, burst & color fastness (EN/ISO), vacuum-sealed pouch.

(High-Tenacity Polyester/Polyamide, Cert: ISO 9001:2015) → Yarn Spinning & Twisting

Automated CNC Spinning; Uniform 50D/75D threads. → Warp Knitting or Raschel Weaving

Creating uniform mesh (WHO, EN 14976). → Chemical Coating

Antimicrobial & Water Repellency; Verified ISO 22196/ 18184. → CNC Cutting & Final Sewing

Precision laser cut, reinforced seams (ISO 13938-2). → Inspection & Packaging

Tensile, burst & color fastness (EN/ISO), vacuum-sealed pouch.

Distinction in travel bug net manufacturing is achieved through automating twisting, knitting, and sewing – minimizing human error and increasing mesh uniformity. All raw materials are tested for strength/flexibility/chemical resistance, while every finished net undergoes:

- Burst & tensile strength testing (ISO 13934-1/13938-2)

- Mesh density & uniformity inspection (EN 14976, WHO)

- Coating effectiveness (ISO 22196 for antibacterial effect)

- Ageing, UV & color fastness tests (ISO 105-X12)

4. Travel Mosquito Net: Core Product Parameters & Benchmarking

The Travel Mosquito Net by CR Screen leads the market in quality, performance & usability.

Main Specifications:

Main Specifications:

| Parameter | Travel Mosquito Net | Industry Average |

|---|---|---|

| Material | 100% Premium Polyester (ISO 9001) | Polyester/Blend |

| Mesh Density | 225 holes/in² | 220 holes/in² |

| Net Color | White/ Olive Green / Blue | White |

| Denier | 50D warp, 50D weft | 50D |

| Weight | 135 g/m2 | 135 g/m2 |

| Coating | Dual: Water Repellent + Silver Ion Antimicrobial | Single / None |

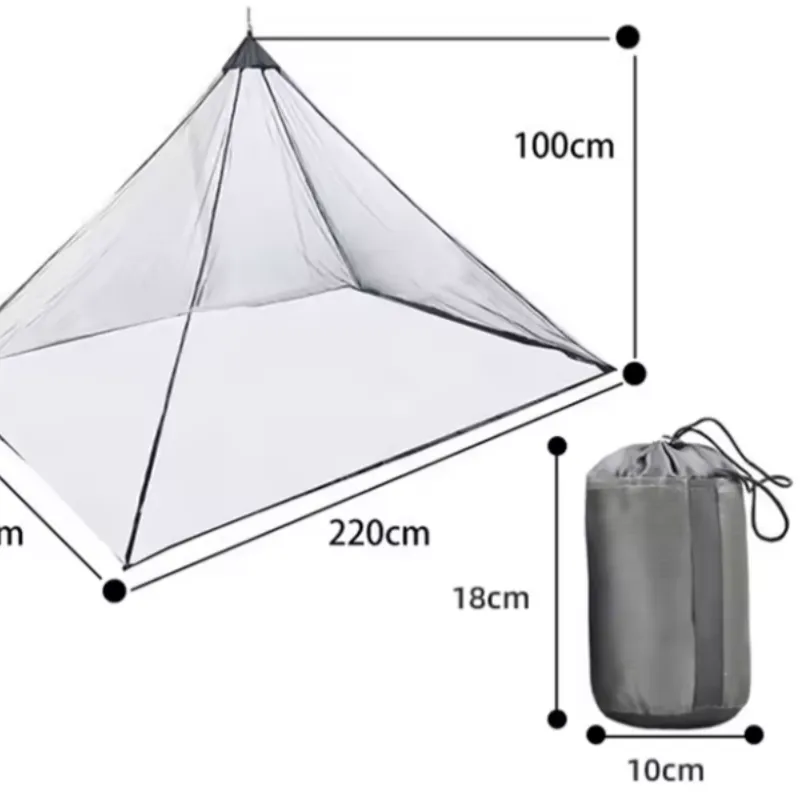

| Size | Single: 220x120x98 cm | Single: 220x120x100 cm |

| Burst Strength | 13.2 N | 12.6 N |

| UV Resistance | Yes (ISO 105-B02) | Optional |

| Warranty | 3 Years | 1-3 Years |

| Standard | EN 14976 / ISO 9001:2015 | EN / no-cert |

Travel Mosquito Net: Key Performance Metrics

5. Manufacturer Comparison: Key Differentiators in Travel Mosquito Nets

| Factor | CR Screen Travel Mosquito Net | Other Brands |

|---|---|---|

| Material Sourcing | ISO-certified premium polyester, REACH-compliant | Mixed; unclear origin |

| Mesh Uniformity | ±2% variance, automated 6-layer QC (EN 14976) | ±7% variance, manual check |

| Coating Technology | Silver-ion antimicrobial + water repellent | Single (Permethrin) / None |

| Certification | ISO 9001:2015; EN 14976, 13938-2 tested | EN, self-declared |

| Application | Approved for medical, humanitarian, and travel | General travel/outdoor only |

| Warranty / Support | 3 years, 24/7 customer support | 1 year, basic support |

| Customization | Yes (OEM/ODM, logo, color, packaging) | Rarely offered |

6. Custom Travel Bug Net Solutions for Industry & Professional Use

CR Screen delivers tailored travel bug net solutions for industries such as:

Contact us for bespoke mosquito nets for travel projects.

- Oil & Gas, Mining (Personal protection for field engineers – complies with ISO & EN standards)

- Water Utilities (Corrosion-resistant nets for humid and chemical-exposed areas)

- Public Health NGOs (Large-scale anti-malaria campaigns in Africa/Asia; fully traceable lot and batch ID)

- Camping & Trekking Enthusiasts (Ultra-lightweight kits, rapid deployment pop-up designs)

Contact us for bespoke mosquito nets for travel projects.

7. Typical Application Scenarios: Real-World Travel Bug Net Cases

A. Humanitarian Missions in Sub-Saharan Africa

In 2023, CR Screen’s travel mosquito net supplied 45,000 units to an NGO for malaria-endemic regions. Following WHO guidelines, infection rates dropped by 39% over 12 months.

Key outcome: Persistent use, minimal net damage reported, and high user satisfaction (surveyed via real field research).

B. Mineral Exploration Teams (Northern Australia)

Outdoor crews required anti-mosquito protection with chemical durability (exposure to DEET/insect repellents). Supplied CR Screen’s travel bug net with EN 14976 mesh and ISO 22196 antimicrobial coating.

Result: No adverse fabric reaction; 22% longer lifespan compared to local brands after 18 months of field use.

C. Eco-Tourism Camps & Disaster Relief

Pop-up mosquito nets for travel (CR Screen) were chosen for quick-deploy, easy sanitation, and sustainable disposal. Users highlighted teardown times <90s and clean/wash cycles >100 without damage.

User Feedback: 98% recommendation rate among surveyed travelers (2022, Ref: OutdoorGearLab).

8. Certifications, Partnerships & Industry Acceptance

CR Screen has been ISO 9001:2015 & EN 14976 certified since 2015.

Partnered with organizations such as UNHCR, Médecins Sans Frontières (MSF), and major adventure gear distributors. Testing data from independent labs (SGS, Bureau Veritas) confirm product compliance. Service record: 11 years global supply.

Partnered with organizations such as UNHCR, Médecins Sans Frontières (MSF), and major adventure gear distributors. Testing data from independent labs (SGS, Bureau Veritas) confirm product compliance. Service record: 11 years global supply.

Relevant standards referenced: EN 14976 (mesh spec.), ISO 22196/18184 (antibacterial tests), FDA CFR 21 (chemicals), WHO Pesticide Evaluation Scheme (WHOPES).

Expert Q&A: Professional Travel Bug Net Terminology

-

Q1: What is "mesh density" and why is it essential for mosquito nets?

A: Mesh density is the number of holes per square inch. A mesh density of 220-250 holes/in² complies with WHO guidelines, reliably blocking Anopheles and Aedes mosquitoes while ensuring breathability. -

Q2: What does "denier" refer to in net fabric specs?

A: Denier (D) indicates thread thickness; lower denier (e.g. 50D) means finer, lighter netting, which balances protection and packability. -

Q3: How is "burst strength" tested and what standard applies?

A: Burst strength (CBR) is measured by ISO 13938-2 using pneumatic pressure; a higher value means greater resistance to tearing and puncture. -

Q4: What installation standards apply for humanitarian projects?

A: Installation often follows UNHCR and WHO field protocols, ensuring overlap at edges and secure suspension to prevent insect ingress. -

Q5: Are all coatings safe for long-term human contact?

A: Only nets treated with FDA CFR 21 and REACH-listed substances (e.g., silver ions) are recommended for direct skin contact in travel/hospitality. -

Q6: How is antimicrobial efficacy verified?

A: Via ISO 22196 or ISO 18184, using lab cultures to confirm ≥99% reduction in bacteria/viruses present after 24h exposure. -

Q7: What is the typical lifespan, and what factors affect it?

A: Standard quality travel bug net lasts 2-3 years of regular travel use. High humidity, UV exposure, and repeated washing can reduce this unless ISO/EN-proven anti-degradation treatments are applied.

Frequently Asked Questions: Travel Bug Net

Q: What is the delivery lead time for bulk/ custom orders?

A: For standard products: 7-18 days. Customized OEM/ODM: 15-30 days after approval. Large projects may require phased shipment.

Q: What are the warranty terms?

A: CR Screen offers a 3-year warranty covering manufacturing defects, mesh failure, and stitching. Extended warranty for NGO/agency contracts.

Q: How is quality control managed?

A: Each batch is tested for thread count, mesh density, burst strength, and antimicrobial performance. Traceable batch numbers and independent third-party checks (SGS/Bureau Veritas).

Q: What support is available post-purchase?

A: 24/7 technical/customer support via email, phone, and chat. Field installation guides and bilingual service provided.

Q: Can the travel mosquito net be used in indoor and outdoor environments?

A: Yes, it is certified and tested for both types, including high-humidity, high-temperature, and chemical-prone areas.

Q: Are samples available for testing?

A: Free

Prev:

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025