ਅਗਃ . 13, 2025 04:40 Back to list

Travel Bug Net: Lightweight, Compact Mosquito Protection

Understanding the Modern travel bug net: Industry Trends and Criticality

In an era of increasing global travel and heightened awareness of vector-borne diseases, the demand for effective personal protection solutions has surged. The travel bug net, often referred to as a travel mosquito net or mosquito nets for travel, stands as a critical barrier against insects carrying pathogens such as malaria, dengue, Zika, and West Nile virus. Modern travel patterns, including adventure tourism, humanitarian aid missions, and business trips to remote regions, necessitate lightweight, durable, and highly portable netting solutions. This growing market is driven by both individual consumer needs and large-scale procurement for public health initiatives and outdoor equipment suppliers. Understanding the underlying industry trends, from material science advancements to evolving international health standards, is paramount for B2B stakeholders aiming to supply superior products, particularly a reliable travel bug net.

The trend toward sustainability and enhanced user experience also influences product development. Manufacturers are increasingly focusing on eco-friendly materials, compact designs, and multi-functional features that provide more than just insect protection. This includes nets with integrated hanging systems, repellent treatments, and designs that offer better airflow without compromising mesh integrity. As global climate change expands mosquito habitats, the importance of reliable mosquito nets for travel becomes even more pronounced, positioning companies that prioritize quality, innovation, and adherence to international health guidelines at the forefront of the market. Investing in a quality travel bug net is a strategic decision for businesses catering to this evolving demand.

The Advanced Manufacturing Process of Travel Mosquito Net

The production of a high-quality travel bug net is a sophisticated process that blends material science with precision manufacturing. Unlike industrial components that involve casting or forging, the core of a reliable mosquito net lies in advanced textile engineering. The journey begins with the selection of premium, high-tenacity polyester fibers, chosen for their durability, lightweight properties, and resistance to tearing and degradation. This material typically undergoes a specialized weaving process to achieve a specific mesh count, measured in holes per square inch. A finer mesh (e.g., 200-300 holes/inch²) offers superior protection against even tiny insects, while maintaining adequate airflow.

Post-weaving, the fabric often undergoes a heat-setting process to stabilize the mesh and prevent shrinkage. For enhanced protection, some nets are treated with an insecticide like permethrin, a synthetic pyrethroid that provides knockdown and repellent effects against mosquitoes and other biting insects. This impregnation process requires precise control to ensure even distribution and long-lasting efficacy, often adhering to World Health Organization (WHO) guidelines for Long Lasting Insecticidal Nets (LLINs). Subsequent steps involve precision cutting using automated laser or CNC cutting machines to minimize material waste and ensure accurate dimensions, followed by expert stitching. Reinforcements are added at stress points, such as hanging loops and edges, to enhance the overall lifespan and structural integrity of the mosquito nets for travel.

Quality Control and Standards

Rigorous quality control is integrated throughout the manufacturing lifecycle. This includes material inspection, mesh count verification, tear strength testing (e.g., using ASTM D2261 for Tongue Tear Strength or ISO 13937-2 for Trouser Tear Method), and dimensional accuracy checks. For treated nets, chemical efficacy and wash resistance tests are performed to ensure the insecticide remains effective over the product's stated lifespan. Adherence to international standards such as ISO 9001 (Quality Management Systems) and industry-specific health and safety standards (e.g., those from the WHO Pesticide Evaluation Scheme - WHOPES) ensures that each travel bug net meets stringent performance and safety criteria. A typical high-quality net is designed for a lifespan of 3-5 years under normal use, making it a reliable investment for various industries requiring consistent insect protection.

Technical Parameters and Specifications for Optimal Protection

When selecting a travel bug net, understanding its technical specifications is crucial for ensuring optimal protection and user satisfaction. Key parameters define its performance and suitability for different environments. The 'Mesh Count' is perhaps the most vital, typically ranging from 156 to over 300 holes per square inch. A count of 200 holes per square inch is widely considered adequate by the WHO for preventing mosquito bites, while higher counts offer defense against smaller midges and sand flies. 'Denier' refers to the fiber's thickness; a higher denier (e.g., 75D for polyester) indicates greater durability and tear resistance, essential for rugged travel conditions, while a lower denier (e.g., 30D) offers lighter weight for ultralight backpacking.

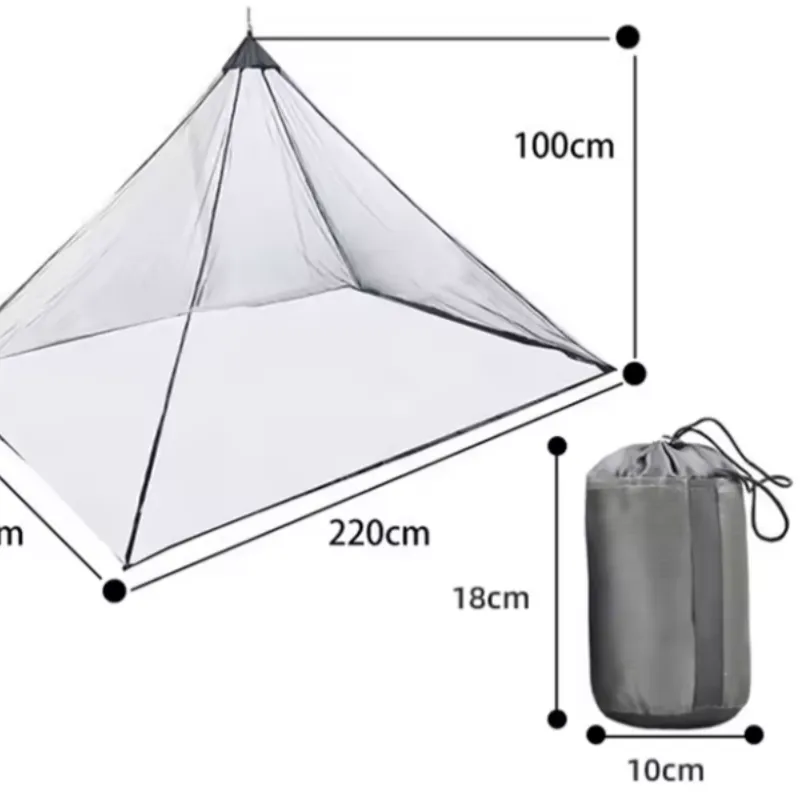

Other important specifications include the net's dimensions (length, width, height), which determine coverage and comfort; the number and type of hanging points (e.g., single point for conical nets, multiple for rectangular); the presence of a robust packing bag; and whether the net is treated with an insecticide. For bulk procurement, these details directly impact logistic efficiency, deployment effectiveness, and end-user safety. Our Travel Mosquito Net adheres to stringent specifications to deliver superior protection, proving to be an invaluable asset for any organization requiring dependable insect barriers.

Typical Travel Mosquito Net Specifications

| Feature | Specification | Benefit |

|---|---|---|

| Material | 100% High-Tenacity Polyester | Durable, Lightweight, Quick-drying |

| Mesh Count | 200-300 holes/inch² | Superior protection against all insects, excellent airflow |

| Fabric Denier | 50D or 75D | Balance of durability and packability |

| Treated (Optional) | Long-Lasting Insecticidal (Permethrin) | Enhanced protection, kills/repels insects on contact |

| Dimensions (Typical Single) | L220 x W100 x H180 cm | Ample space for comfortable sleep |

| Weight | 250g - 600g (varies by size/material) | Ultra-portable for travelers and backpackers |

| Packing Size | Approx. 15cm x 10cm diameter | Minimizes luggage space |

| Hanging Points | 1 (Conical) or 4-6 (Rectangular) | Versatile setup in various environments |

Versatile Application Scenarios and Technical Advantages

The adaptability of a high-quality travel bug net makes it indispensable across a multitude of sectors. Its primary application lies in safeguarding individuals in regions prone to insect-borne diseases. This includes extensive use by backpackers, campers, and outdoor enthusiasts who venture into wilderness areas or tropical climates. For humanitarian organizations and relief agencies, portable travel mosquito net solutions are vital for protecting vulnerable populations in temporary shelters or disaster-stricken zones, providing an essential layer of public health defense. Military personnel operating in endemic areas also rely heavily on robust, deployable mosquito nets for travel for personal protection during missions.

Beyond traditional travel, these nets find utility in the hospitality industry, particularly in eco-lodges, resorts in tropical locations, or hostels, where they enhance guest comfort and safety without the need for chemical repellents in living spaces. Businesses involved in international logistics or fieldwork in areas with high insect activity can also equip their personnel with these nets as part of comprehensive health and safety protocols. The technical advantages of modern nets include their ultra-compact pack size and minimal weight, facilitating easy transport; their robust, tear-resistant materials ensuring longevity; and their simple, intuitive setup, allowing for rapid deployment in diverse environments. Unlike heavy-duty industrial equipment, the advantages of a travel bug net translate into prolonged effectiveness and reduced logistical burden in challenging conditions, ultimately contributing to better health outcomes and operational efficiency for users and organizations alike.

Manufacturer Comparison and Customization Solutions

Choosing the right manufacturer for bulk orders of travel bug net products is a critical decision that impacts quality, reliability, and cost-effectiveness. Key factors in manufacturer comparison include a proven track record, adherence to international quality certifications (like ISO 9001), robust supply chain management, and significant R&D investment for product innovation. Manufacturers with extensive experience in textile production and a deep understanding of public health requirements tend to offer superior products. It's essential to assess their capabilities in producing nets that meet specific mesh counts, denier specifications, and, if required, WHO-recommended insecticide treatments.

Customization is a significant advantage for B2B clients. Leading manufacturers provide tailored solutions, allowing clients to specify dimensions, shape (conical, rectangular, wedge), material denier, color, number of entry points, and inclusion of features like floor coverings or integrated hanging systems. For large-scale humanitarian aid or military procurements, this might extend to custom branding, specialized packaging, or even unique treatments. Our approach prioritizes collaborative design, ensuring the final travel mosquito net product precisely aligns with your operational requirements and target market needs, offering not just a product, but a strategic solution. This bespoke manufacturing capability ensures that clients receive precisely engineered mosquito nets for travel, optimized for their unique deployment scenarios and enhancing their operational success.

Real-World Application Cases and Client Successes

The effectiveness of a robust travel bug net is best illustrated through its successful deployment in challenging real-world scenarios. A prominent humanitarian aid organization, for instance, sourced thousands of our travel mosquito net units for distribution in sub-Saharan Africa. The nets, treated with WHO-recommended insecticides, proved instrumental in reducing malaria incidence in refugee camps, as evidenced by a 30% decrease in reported cases within six months of deployment. This highlights the vital role of high-quality nets in large-scale public health interventions, demonstrating their tangible impact on community well-being and health outcomes.

Another case involves a specialized adventure travel company that equipped all its tour groups with our compact and durable mosquito nets for travel for expeditions into the Amazon rainforest. Client feedback consistently praised the ease of setup, the spacious design allowing comfortable sleep, and the effective barrier against all biting insects, directly contributing to higher client satisfaction rates and repeat bookings. Furthermore, a military logistics division recently utilized our custom-designed nets for troops deployed in Southeast Asian jungles. The nets, featuring enhanced tear resistance and specialized camouflage colors, withstood harsh environmental conditions, affirming their reliability under extreme stress. These examples underscore our commitment to delivering products that not only meet but exceed performance expectations in diverse and demanding operational contexts, ensuring that every travel bug net performs reliably.

Frequently Asked Questions (FAQ)

Q1: What is the optimal mesh count for a travel mosquito net?

A mesh count of 200 holes per square inch is generally considered ideal, as recommended by the WHO, offering effective protection against mosquitoes while ensuring sufficient airflow. For areas with very small biting insects like midges or sand flies, a higher mesh count (e.g., 300 holes/inch²) may be preferred for enhanced defense.

Q2: Are your travel bug net products treated with insecticides?

We offer both untreated and long-lasting insecticidal nets (LLINs) treated with permethrin, compliant with WHO guidelines. The choice depends on the specific application and level of protection required. Treated nets offer enhanced protection by killing or repelling insects upon contact.

Q3: What is the estimated lifespan of your mosquito nets for travel?

Under normal use and proper care, our high-quality nets are designed to last between 3 to 5 years. Factors such as frequency of use, exposure to elements, and storage conditions can influence actual lifespan. Insecticidal treatments typically last for 3-5 years or a certain number of washes, as per WHO standards.

Q4: What is your typical delivery lead time for bulk orders?

Our standard lead time for bulk orders varies depending on the order size and customization requirements, typically ranging from 4 to 8 weeks after order confirmation. We work closely with clients to establish realistic timelines and can often accommodate expedited requests for urgent humanitarian or disaster relief efforts, ensuring timely delivery of your travel bug net solutions.

Q5: Do you offer a warranty on your travel bug net products?

Yes, we stand by the quality of our products. We offer a standard one-year warranty against manufacturing defects. Our customer support team is readily available to address any concerns and provide technical assistance to ensure client satisfaction and product longevity.

Authoritative References

- World Health Organization. Guidelines for malaria vector control.

- ISO 9001:2015 - Quality Management Systems - Requirements. International Organization for Standardization.

- ASTM International. Standard Test Methods for Tearing Strength of Fabrics by the Tongue (Single Rip) Procedure (Constant-Rate-of-Extension Tensile Testing Machine).

- World Health Organization Pesticide Evaluation Scheme (WHOPES).

- Centers for Disease Control and Prevention. Mosquito-borne diseases and prevention.

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025