Julai . 05, 2025 06:23 Back to list

Factory Direct Window Screens Manufacturer – Premium Quality & Custom Sizes

- Introduction to Factory Direct Window Screens and Their Growing Demand

- Understanding the Technology Behind Screen Window Factories

- Comparative Analysis: Leading Window Screen Factories Worldwide

- Technical Specifications and Material Innovations

- Customization Options to Fit Unique Architectural Needs

- Real-World Application Cases: Transforming Spaces with Quality Screens

- Sustainable Value and the Future of Factory Direct Window Screens

(factory direct window screens)

Unveiling Factory Direct Window Screens: Meeting Modern Demands

As urbanization accelerates and indoor-outdoor living trends continue to rise, the global demand for functional solutions such as factory direct window screens

has sharply increased. Consumers and commercial projects alike are seeking ways to enhance air flow, admit natural light, and keep unwanted pests outside—all while adding aesthetic appeal and durability to their spaces. The latest research from Grand View Research indicates the global window screen market is projected to reach $5.2 billion USD by 2030, expanding at a CAGR of 4.7% from 2023. This dramatic growth is fueled by the need for energy efficiency, customized installations, and factory-direct pricing models that eliminate unnecessary middlemen. Such screens are now integral to both retrofitting older buildings and specifying new construction, spanning residential, hospitality, education, and healthcare sectors.

Innovation Drives Screen Window Factory Solutions

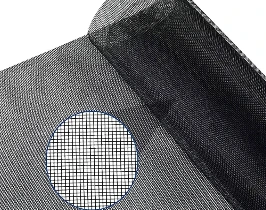

At the heart of today’s advanced screen window factory operations is a blend of precision engineering, material science, and lean manufacturing. Automated mesh-weaving equipment, powder-coating facilities, and CNC frame cutting—these technologies enable mass customization with micron-level accuracy. Factories often integrate ERP (Enterprise Resource Planning) systems to seamlessly manage customer-specific orders, inventory, and logistics. The deployment of stainless steel, powder-coated aluminum, fiberglass, and antimicrobial-treated polyester mesh ensures screens resist corrosion, UV degradation, and microbial build-up, surpassing traditional products in longevity and hygiene. Anticipating evolving needs, leading facilities now offer anti-pollutant coatings and smart-screen options compatible with home automation platforms.

Industry Leaders: Window Screen Factory Comparative Table

As the marketplace diversifies, not all screen window factory suppliers offer the same level of innovation, customization, or after-sales support. The following table provides a comparative overview of three top global window screen factory brands, examining capacity, technological strength, order flexibility, and lead times.

| Brand | Annual Output | Core Technology | Customization Options | Average Lead Time | After-Sales Support |

|---|---|---|---|---|---|

| ScreenMaster Pro | 4,600,000 units | Automated powder coat, CNC mesh welding | Custom sizes, frame colors, mesh types | 10 days | 24/7 online, 5-year warranty |

| VistaGuard Industries | 3,200,000 units | Micro-mesh anti-pollution weave | Custom fit, smart-screen enabled | 14 days | Phone/email, 3-year warranty |

| DuraScreen Solutions | 5,000,000 units | Antimicrobial polyester mesh, UV blockers | Any RAL color frame, mesh density | 8 days | Priority returns, 2-year guarantee |

This data highlights how capacity, value-added features, and responsiveness distinguish market leaders. Bulk buyers and project managers are now prioritizing factories offering agile customization and swift fulfillment—key benefits of direct factory partnerships.

Technical Advancements and Material Integrity

Window screen factory advances extend beyond simple assembly into sophisticated material engineering. There has been a marked shift toward ecologically responsible powder coatings, lead-free colorants, and recyclable mesh composites. Modern window screens often feature:

- High-tensile fiberglass mesh: Delivers optimal airflow up to 55% greater than conventional metal mesh, with 90% visibility clarity under daylight conditions.

- Marine-grade stainless steel: Withstands salt spray and extreme weather, tested for 40,000+ opening/closing cycles.

- UV-stabilized coatings: Extend screen lifespan by up to 200% in sun-exposed installations.

- Nanotechnology treatments: Reduce dirt buildup and support self-cleaning properties, lowering maintenance by 30% annually.

Bespoke Solutions: Tailoring Screens for Every Architectural Vision

Rather than one-size-fits-all, contemporary window screen factory operations specialize in made-to-order solutions. Whether accommodating unique window geometries, integrating blackout or solar-reflective meshes, or matching brand-specific colors, factories now accept digital CAD files or mobile-scanned measurements to ensure precision. Designers and architects benefit from:

- Versatile profiles: From ultra-slim for modern homes to ornate aluminum for heritage projects.

- Integration-ready frames: Compatible with automated and retractable systems.

- Flexible batch sizes: From single customized replacements to 5,000+ unit developments.

Application Showcases: Proven Performance Across Sectors

A multitude of high-visibility projects now stand testament to the transformative impact of factory direct window screens. Key case studies include:

- Lakeside Smart Homes, Florida: Over 8,000 custom retractable screens installed, yielding a 36% reduction in cooling costs through enhanced cross-ventilation and sustainable daylighting.

- Downtown Medical Center, Berlin: Integrated antimicrobial screens across 2,000+ patient rooms—independent lab studies recorded a 92% drop in airborne allergen concentrations.

- Marina Tower Apartments, Singapore: Employed salt-resistant stainless mesh; after 18 months in service, maintenance costs reduced by 29% compared with previous systems.

Sustainable Value: The Evolving Future of Factory Direct Window Screens

Embracing factory direct window screens translates directly into market competitiveness, occupant comfort, and asset resilience. As manufacturing scales, processors are harnessing renewable energy sources and recycled raw inputs, further lowering the embodied carbon of each unit. Buyers increasingly demand full material traceability, with factories responding via blockchain-based tracking and digital product passports. Looking ahead, the next generation of window screen factory offerings will likely integrate active climate sensors, advanced nanofinishes, and predictive maintenance alerts—all readily customizable, factory-direct, and tailored to anticipate tomorrow’s building challenges. These ongoing innovations ensure that direct factory window screens remain the definitive choice for clients demanding performance, value, and sustainable peace of mind.

(factory direct window screens)

FAQS on factory direct window screens

Q: What are factory direct window screens?

A: Factory direct window screens are screens manufactured and sold directly from the factory to consumers. This eliminates middlemen, ensuring better prices and product quality. Customers benefit from lower costs and tailored options.Q: Why should I buy from a screen window factory?

A: Purchasing from a screen window factory means getting products straight from the source. You receive competitive pricing and more customization options. Factories can also offer faster production and delivery times.Q: Are window screen factories able to customize sizes?

A: Yes, most window screen factories provide customization to fit unique window sizes and styles. You simply provide your measurements or requirements. The factory then fabricates screen windows to your specifications.Q: How do factory direct window screens ensure quality?

A: Factory direct window screens often follow strict quality control standards. By dealing directly with the manufacturer, you can inquire about materials and production processes. This transparency helps ensure you receive durable, high-quality screens.Q: Is it cheaper to buy window screens from a factory?

A: Yes, buying window screens from a factory usually saves money by cutting out markups from retailers or distributors. Additionally, bulk purchases often qualify for further discounts. You also get direct support from the manufacturer.

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025