Nov . 07, 2024 18:20 Back to list

From Parts To Finished Products: The Behind Story Of Sliding Window Production Line

In modern architecture, sliding screen windows are increasingly favored by consumers because of their unique design and superior functionality. However, have you ever wondered how these beautiful screen windows go from parts to finished products? Today, we take you behind the story of the insect screen sliding window production line.

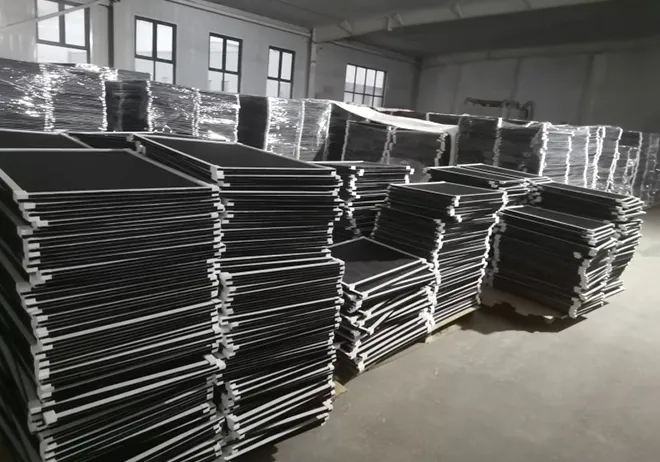

In our factory, the sliding screen windows are assembled by hand by workers. Each person is responsible for one step until the assembly is complete. This assembly process is described below.

First step——the assembly of rubber strips

Glue the strip to the window screen frame in the correct direction to ensure that it is evenly fitted; Then gently press the strip with your fingers to ensure its firm adhesion and complete the assembly.

Second step——assemble the sliding window frame

Assemble the frame with the rubber strip, and the assembly is more difficult. You can use a small hammer to smash it firmly.

Third step——Yarn pressing

Place a piece of cut screen over the assembled frame and secure the screen to the frame with a yarn press tool.

Last step——Assemble two panels into a sliding screen window.

Through the operation of the above steps, a piece of screen panel will be made, and then the two panels will be assembled into a push-pull screen through the buckle, so that the push-pull screen is completed.

No screen leaves the factory without thorough testing. Quality control teams inspect each sliding screen for defects, ensuring mesh tightness, frame alignment, and smooth sliding action. This phase is essential, as it identifies any potential issues before the screen reaches customers. Screens are also tested for durability against weather, ensuring they can withstand rain, wind, and sun exposure.

This is the last article

Products

Latest news

-

Unveiling the Allure and Practicality of Classic Mosquito Nets

NewsJul.04,2025 -

Unraveling the World of Mosquito Nets: Varieties, Costs, and Production

NewsJul.04,2025 -

Redefining Protection and Style: The World of Mosquito Nets

NewsJul.04,2025 -

Enhancing Sleep and Style with Contemporary Mosquito Nets

NewsJul.04,2025 -

Diverse Solutions in Mosquito Netting: Sizes, Varieties, and Flexibility

NewsJul.04,2025 -

Deciphering Mosquito Nets: Significance, Varieties, and Applications

NewsJul.04,2025 -

Transforming Bedrooms into Mosquito - Free Havens

NewsJul.01,2025